I'm wondering if any one knows what the optimum headspace is in a 6.5 Grendel AR15? Headspace here that I'm refering to is the distance between the bolt face and the cartridge case head when the action is locked. Most measurements I'm referencing are taken using an L.E. Wilson case gauge and a dial indicator. Factory loadings from Wolf and new brass from Lapua are .008" to .009" below SAAMI MAXIMUM for this cartridge, .003" to .004" below SAAMI minimum. Once fired brass gauges at .010" above SAAMI MAXIMUM, for a total stretch on firing of .018" to .019". Total resizing results in fairly rapid weakening of the case walls and leads to case walls failing forward of the case head. My bolt will not close on a PTG no-go gauge, which is .005" above SAAMI MAX., but it will close on a fired case, cleaned only, which registers .004" above SAAMI MAX. From this I'm guessing that there is .012" to .013" of headspace when either of these two rounds are loaded. This seems like a lot of headspace; I had an experience with a T/C Contender which had exccessive headspace of .008" to .009" and I was getting flattened primers, cupped and extruded primers and primers with the center blown out, all with factory loads. All signs disappeared when the breech face was shimmed to give a recommended headspace of .002" to .003". My plan is to hold the shell holder away from the FL die in the Grendel and allow the resized cases to protrude perhaps .002" above SAAMI MAX. This should give me about .002" of headspace. The other thing is that there is another .006" of stretch that I can't directly account for. Either the gun is stretching, (not likely because of the proximity of the locking lugs to the case head), or the case is continuing to stretch during that instant when the bolt starts to unlock, but before there is a significant reduction in pressure. After all this, my question is whether a headspace of .002" in the AR15 Grendel will compromise consistent bolt closure? This is in an Alexander upper circa 2007.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

Quick Shot Challenge: What’s the most underrated gear you never leave home without?

Contest ends Wednesday, join now for the chance to win free Hide merch!

Join contest

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing Headspace in 6.5 Grendel AR15

- Thread starter Lew Hodge

- Start date

-

- Tags

- 6.5 grendel problem

I had a Sabre def. Grendel barrel with excessive headspace that gave me fits until I finally figured out what was going on. Same issues you were seeing with that TC, pressure signs etc. I could never get it to group well either, always shot two groups, two in one spot, three in the other. Messed with it off and on for years till I finally bit the bullet and re barreled it.

It should run fine leaving the cases sized long, but its still not going to be ideal. And I wouldn't go chasing velocity with pressure if this is going to be your solution rather than a re barrel. I'd also run some of the heavier walled brass in it. I've noticed that my Lapua brass is thinner at the web than the Hornady brass I have. It tends to show more stretching when unsupported. Assuming they're still made to the same specs I would recommend you use the heavier Hornady (or one of the other makers doing 6.5G brass now) if they also have a heavier wall. You could also fireform 7.62x39 brass which is thicker. I used to do it when actual Grendel brass was still hard to come by. I bought myself a bunch of KP (made by Lapua) 7.62x39 for half what 6.5g was going for and that got me started. Very simple process for this cartridge but you'll have slightly shorter necks.

As far as reliability, hard to say. If you're keeping the chamber fairly clean I doubt you'll ever have an issue. Even just stuffing a chamber brush in every 100 rounds or so (not a full cleaning) will probably keep you trouble free.

It should run fine leaving the cases sized long, but its still not going to be ideal. And I wouldn't go chasing velocity with pressure if this is going to be your solution rather than a re barrel. I'd also run some of the heavier walled brass in it. I've noticed that my Lapua brass is thinner at the web than the Hornady brass I have. It tends to show more stretching when unsupported. Assuming they're still made to the same specs I would recommend you use the heavier Hornady (or one of the other makers doing 6.5G brass now) if they also have a heavier wall. You could also fireform 7.62x39 brass which is thicker. I used to do it when actual Grendel brass was still hard to come by. I bought myself a bunch of KP (made by Lapua) 7.62x39 for half what 6.5g was going for and that got me started. Very simple process for this cartridge but you'll have slightly shorter necks.

As far as reliability, hard to say. If you're keeping the chamber fairly clean I doubt you'll ever have an issue. Even just stuffing a chamber brush in every 100 rounds or so (not a full cleaning) will probably keep you trouble free.

Thanks Vodak; great advice! Strange, that I did find the Grendel's sweet spot last year; it was 27.5 gr. AR Comp behind a 120gr. A-Max by Hornady. All bullets in pretty much the same hole, way less than 1/4" center to center and with all load increments; the headspace issue notwithstanding! Of course, as soon as I got there, Hornady ceased production of the A-Max. I'm fiddling around with Hornady SSTs now, but results are similar to what you had with the Sabre def. Scenars are the same and I have never had a decent group with Nosler Partition! Great 3 shot group, with the other two off somewhere. I also have PPV brass, from the days when that was all you could get from Alexander. Primer pockets seem to swell in these cases; after a few cycles, primers won't hold. I have favored case life over a few more fps. For now, I will try setting cases long and see what happens. UnfortunatlyI have a new box of Lapua that I am loading right now, but this will be a test, leaving the cases long after the very first firing, with no total resizing. Hornady brass will be next. Thanks again for your reply; it is greatly appreciated! BTW, is there a die set to convert from 7.2X39 to Grendel?

Lew

Lew

Have you tried the ELD-M's? I think they're supposed to be pretty close to the A-Max with a different compound of plastic in the tip.

You don't need any special dies. Just run the 7.62x39 brass into your full length sizing (well lubed in the neck) and it will put a tiny shoulder in and size just the neck down to fit. Use a slower powder, back down at least a full grain from published minimums and let them rip. I was getting almost as good results while fireforming as I was with factory brass shooting at 100Y. If the factory brass works for you its not really worth the effort. But if you're seeing stretching still it might be worth a try. There are some old posts still available on the Grendel forums with more info that you should definitely familiarize yourself prior to attempting it.

You don't need any special dies. Just run the 7.62x39 brass into your full length sizing (well lubed in the neck) and it will put a tiny shoulder in and size just the neck down to fit. Use a slower powder, back down at least a full grain from published minimums and let them rip. I was getting almost as good results while fireforming as I was with factory brass shooting at 100Y. If the factory brass works for you its not really worth the effort. But if you're seeing stretching still it might be worth a try. There are some old posts still available on the Grendel forums with more info that you should definitely familiarize yourself prior to attempting it.

Thanks again Vodak! I use full length dies with bushings; are you going from 30 cal. to 6.5 in one neck sizing operation? I could break up the process by using several different bushings, easing the neck down to 6.5. Do you have a favorite company for the 7.62 X 39 brass? Do you recommend neck reaming after this operation? I could go back to the standard FL die, if the bushings don't have sufficient taper to do this. I suspect that they don't. Will put ELDs on list.

I used a one piece die and did it in one shot. It's just the neck that's being moved, and only 1mm. If the brass is new, or freshly annealed it should be fine. I was fortunate enough to find a few hundred pieces of new KP branded brass, which was made by Lapua. That was the best of what I used. But I also had acceptable results from some small runs of Winchester, Midway branded, and a batch of unmarked brass. Once real Grendel brass became available it just wasn't worth the effort to me anymore.

I do recommend at least checking to see if you're getting a brass doughnut in the neck. When I was doing this I never had a problem with it The false shoulder is formed in the neck of the 7.62x39 case. So it shouldnt be a problem until it's been shot enough to flow forward. I think the most any of my formed cases were shot was probably five times, and I never saw it migrate up to case neck. I did neck turn the unmarked brass as it was pretty wonky. But I didn't have a reamer back then or I might have done it that way for piece of mind. My goal was just to have shootable brass though, not to get precision ammunition out of it.

I have a couple hundred unformed KP cases left just in case I ever feel the need to reload for my AK or some other wildcat. If you can't get the real stuff to work for you, and want to go down this road shoot me a PM, I'd sell you some.

I do recommend at least checking to see if you're getting a brass doughnut in the neck. When I was doing this I never had a problem with it The false shoulder is formed in the neck of the 7.62x39 case. So it shouldnt be a problem until it's been shot enough to flow forward. I think the most any of my formed cases were shot was probably five times, and I never saw it migrate up to case neck. I did neck turn the unmarked brass as it was pretty wonky. But I didn't have a reamer back then or I might have done it that way for piece of mind. My goal was just to have shootable brass though, not to get precision ammunition out of it.

I have a couple hundred unformed KP cases left just in case I ever feel the need to reload for my AK or some other wildcat. If you can't get the real stuff to work for you, and want to go down this road shoot me a PM, I'd sell you some.

Been checking 7.62X39mm brass; none available except Lapua from Midway. Everyone else is out. Lapua brass has had some issues lately. I really need to neck ream Grendel cases; the inside of the necks is not really ready to go; getting way different amounts of force to seat bullets. Chamfering necks , of course. My understanding is that neck reaming is to be done after firing, so there's nothing I can do until the first firing. Reamers are out too, Brownell's and Midway. Other retailers are light weight when it comes to anything precision. For now I will load my last box of A-Max, hold short in the resize die and see what kind of case life I'll end up with.

I load for many calibers from 50 BEO down to 204 Ruger and a number of pistols up to 460 S&W. I live in N. Idaho and there's no point going out into the forest with a backup gun that won't do the job. If you've got any tips for loading, I'd be happy to hear them. Thanks again.

One thing I did learn from a forum, is to try full synthetic motor oil (5W20 in this case) as sizing lube. Particularly with resizing 50 BEO cases, it's nearly impossible to get the case into the die with other lubes and getting it out of the press is a nightmare, where I've expected the rim to snap off every time. The synthetic oil is probably the slipperiest stuff on the planet and sizing these cases has become a breeze. Only drawback is that you have to clean again to remove oil. It's worth it, to save my shoulders and the press, not to mention the cases.

Lew

I load for many calibers from 50 BEO down to 204 Ruger and a number of pistols up to 460 S&W. I live in N. Idaho and there's no point going out into the forest with a backup gun that won't do the job. If you've got any tips for loading, I'd be happy to hear them. Thanks again.

One thing I did learn from a forum, is to try full synthetic motor oil (5W20 in this case) as sizing lube. Particularly with resizing 50 BEO cases, it's nearly impossible to get the case into the die with other lubes and getting it out of the press is a nightmare, where I've expected the rim to snap off every time. The synthetic oil is probably the slipperiest stuff on the planet and sizing these cases has become a breeze. Only drawback is that you have to clean again to remove oil. It's worth it, to save my shoulders and the press, not to mention the cases.

Lew

Had a chance to run a few rounds that were sized long through the Grendel. All rounds cycled fine and the group wasn't too bad. Three in one hole and two in another 3/8" away. Interesting that primer flattening has all been but eliminated in a near max. load. The original radius corner on the edge of the primer cup is intact and if there is flattening, I can't see it. Same result as with the T/C after adjusting headspace.

I've been reloading some .223 brass from a couple of friends' ARs. I'm also getting the same .010" reading above SAAMI Max. on once fired cases, (Wilson case gauge), just like my Grendel AR. I haven't tried to close the bolt on these cases, yet, as these are not my guns, but I'm almost certain that the bolt will not close on them. If they did they would be closing on a nogo gauge of .005" above SAAMI Max., PLUS another .005". Again I'm seeing a stretch of around .006" or so in the AR that I cannot account for????

I'm guessing, thinking back to my mechanical engineering days, regarding impact and the elevation of stress levels, that with the ejector pushing the case forward, or at least against the limit of the ejector claw, that a force of 50K PSI, acting against roughly 1/8 sq. in. of the inside of the case head, slamming the case head .019" to .020", free running against the bolt face, could possibly increase the stress by as much as four times, or about 24K #s instead of about 6K#s. This might be a significant factor in premature bolt failure. Only a guess at this point, but interesting.

Did you ever get to measure headspace after rebarreling the Sabre def? I could see rebarreling resulting in the same situation, unless you were lucky enough to get a perfect barrel. Seems that brass manufacturers and maybe gun manufacturers are making their guns to be on the "safe side" of making sure the bolt closes. This is OK for safety, but it makes reloading for accuracy more difficult.

I've been reloading some .223 brass from a couple of friends' ARs. I'm also getting the same .010" reading above SAAMI Max. on once fired cases, (Wilson case gauge), just like my Grendel AR. I haven't tried to close the bolt on these cases, yet, as these are not my guns, but I'm almost certain that the bolt will not close on them. If they did they would be closing on a nogo gauge of .005" above SAAMI Max., PLUS another .005". Again I'm seeing a stretch of around .006" or so in the AR that I cannot account for????

I'm guessing, thinking back to my mechanical engineering days, regarding impact and the elevation of stress levels, that with the ejector pushing the case forward, or at least against the limit of the ejector claw, that a force of 50K PSI, acting against roughly 1/8 sq. in. of the inside of the case head, slamming the case head .019" to .020", free running against the bolt face, could possibly increase the stress by as much as four times, or about 24K #s instead of about 6K#s. This might be a significant factor in premature bolt failure. Only a guess at this point, but interesting.

Did you ever get to measure headspace after rebarreling the Sabre def? I could see rebarreling resulting in the same situation, unless you were lucky enough to get a perfect barrel. Seems that brass manufacturers and maybe gun manufacturers are making their guns to be on the "safe side" of making sure the bolt closes. This is OK for safety, but it makes reloading for accuracy more difficult.

I'm wondering if any one knows what the optimum headspace is in a 6.5 Grendel AR15? Headspace here that I'm refering to is the distance between the bolt face and the cartridge case head when the action is locked. Most measurements I'm referencing are taken using an L.E. Wilson case gauge and a dial indicator. Factory loadings from Wolf and new brass from Lapua are .008" to .009" below SAAMI MAXIMUM for this cartridge, .003" to .004" below SAAMI minimum. Once fired brass gauges at .010" above SAAMI MAXIMUM, for a total stretch on firing of .018" to .019". Total resizing results in fairly rapid weakening of the case walls and leads to case walls failing forward of the case head. My bolt will not close on a PTG no-go gauge, which is .005" above SAAMI MAX., but it will close on a fired case, cleaned only, which registers .004" above SAAMI MAX. From this I'm guessing that there is .012" to .013" of headspace when either of these two rounds are loaded. This seems like a lot of headspace; I had an experience with a T/C Contender which had exccessive headspace of .008" to .009" and I was getting flattened primers, cupped and extruded primers and primers with the center blown out, all with factory loads. All signs disappeared when the breech face was shimmed to give a recommended headspace of .002" to .003". My plan is to hold the shell holder away from the FL die in the Grendel and allow the resized cases to protrude perhaps .002" above SAAMI MAX. This should give me about .002" of headspace. The other thing is that there is another .006" of stretch that I can't directly account for. Either the gun is stretching, (not likely because of the proximity of the locking lugs to the case head), or the case is continuing to stretch during that instant when the bolt starts to unlock, but before there is a significant reduction in pressure. After all this, my question is whether a headspace of .002" in the AR15 Grendel will compromise consistent bolt closure? This is in an Alexander upper circa 2007.

Don't overthink it too much; just back the die out to bump the shoulders back .002-.004" after that first firing and you're good to go. You will see some variation from one case to another, hence the bump range rather than an exact value. Make sure to punch fired primers out of a few cases before using them as your shoulder bump baseline; the primers can affect the reading even if you don't see a crater.

Primer flattening is usually a false pressure sign that is really caused by headspace. As you found out, eliminating the headspace issue gets rid of the primer flattening a lot of the time.

I have not had that much trouble with my 6.5g upper but it is way over gassed.

Could not use my can on it.

New spring and h2 buffer helped and agb waiting for me to get off my lazy ass.

Is it possible you have a type 1 bolt? Causing problems?

I seem to have a tight chamber for a reference my fired brass is 1.218 .

I bump back to 1.214 runs fine.

Hornady factory ammo is 1.212.

This is just a comparison.

Could not use my can on it.

New spring and h2 buffer helped and agb waiting for me to get off my lazy ass.

Is it possible you have a type 1 bolt? Causing problems?

I seem to have a tight chamber for a reference my fired brass is 1.218 .

I bump back to 1.214 runs fine.

Hornady factory ammo is 1.212.

This is just a comparison.

Last edited:

Thanks for your reply Snuby; not sure if I have a type 1 bolt, but it goes back to 2007, so maybe it could be. The only problem I've had with the 6.5G is short case life, with everything discussed before. After the first firing, I can limit stretch and resize to .008" instead of .018 to .019". Can't avoid that big stretch in first firing as long as Lapua and Wolf make short cases.

Are you using a case comparator to measure the shoulder?

One that measures at the shoulder datum (0.350 for 6.5g) to cartridge base?

Or a case gauge as stated earlier?

Something about your wording of that confuses me.

I want to make sure we are talking about the same measurement.

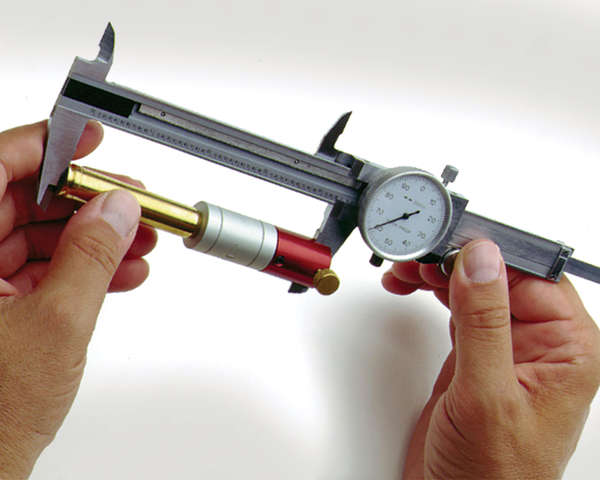

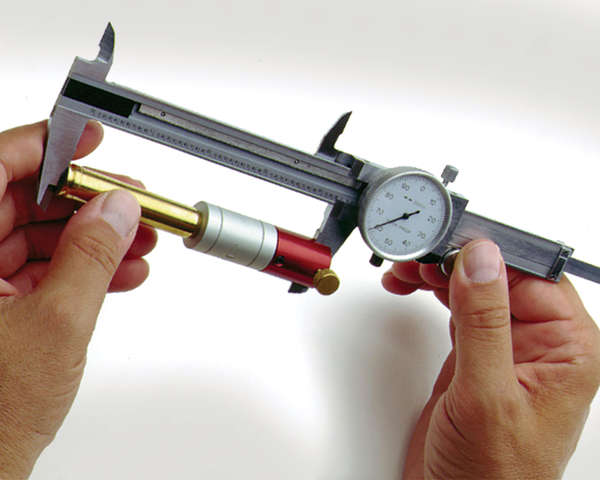

Cartridge gauge

Headspace comparitor

One that measures at the shoulder datum (0.350 for 6.5g) to cartridge base?

Or a case gauge as stated earlier?

Something about your wording of that confuses me.

I want to make sure we are talking about the same measurement.

Cartridge gauge

Headspace comparitor

I've gone by the position of the cases in an L.E.Wilson case gauge. Using that gauge tells me that Lapua ans Wolf unfired cases are .003" to .004" short of SAAMI MIN. If these cases were at SAAMI MAX in the beginnig, I would have a headspace of .004", which would probably be pretty reasonable. BTW, I agree completely about the GD liberals!

You are correct that Lapua sizes their cases a little short; in my chambers (both 6.5 Grendel and 243 LBC, a 6 Grendel wildcat, 4 different barrels total) the Lapua brass results in right about .010" clearance when new. All factory ammo does this to some extent though, most people just don't notice because it's not common to measure shoulder position of loaded factory ammo.

You can get away with up to ~.020" clearance (headspace is what we're really talking about, just based on the actual cartridge and not a gauge) on that first firing, IF you bump shoulders correctly after that. Measuring to the shoulder datum is the best way to do it, and it's really simple with a digital caliper. IME bumping .008" is too much; you'll get much better life from your cases if you adjust that to .002-.004" bump relative to fired cases from that same barrel. That adjustment is as simple as backing the die off a hair and locking down the die lock ring again.

Don't worry about what SAAMI max or min are. Adjust the sizing die to match your chamber, not a SAAMI spec.

You can get away with up to ~.020" clearance (headspace is what we're really talking about, just based on the actual cartridge and not a gauge) on that first firing, IF you bump shoulders correctly after that. Measuring to the shoulder datum is the best way to do it, and it's really simple with a digital caliper. IME bumping .008" is too much; you'll get much better life from your cases if you adjust that to .002-.004" bump relative to fired cases from that same barrel. That adjustment is as simple as backing the die off a hair and locking down the die lock ring again.

Don't worry about what SAAMI max or min are. Adjust the sizing die to match your chamber, not a SAAMI spec.

I never did bother to check it. I have a Wilson case gauge length, but the fired rounds will not fit into it to measure the change. Maybe I'll bore out a 0.350 collar to use as a head space gauge next time I can get in front of a lathe. I do have a few fired and unsized cases sitting around from the barrel still.Did you ever get to measure headspace after rebarreling the Sabre def? I could see rebarreling resulting in the same situation, unless you were lucky enough to get a perfect barrel. Seems that brass manufacturers and maybe gun manufacturers are making their guns to be on the "safe side" of making sure the bolt closes. This is OK for safety, but it makes reloading for accuracy more difficult.

I never did bother to check it. I have a Wilson case gauge length, but the fired rounds will not fit into it to measure the change. Maybe I'll bore out a 0.350 collar to use as a head space gauge next time I can get in front of a lathe. I do have a few fired and unsized cases sitting around from the barrel still.

You can just use a piece of sized 9mm brass the same way. It's a little more awkward to hold that and the Grendel brass you're measuring in the caliper, but it works and is a lot better than just eyeballing a case gauge. The gauge is NOT your rifle's chamber anyway; you should size to the chamber, not the gauge. If you want best results, forget about SAAMI specs and size to match the chamber. Your ammo, your rifle; it doesn't need to match anyone else's standard.

@Yondering Agreed, I would have only been using the gauge to measure growth of the fired case (minus elastic deformation) from a new or fully resized piece of brass. The case gauge would have been usable to measure shoulder set back, but not with my situation. The neck of the gauge being tighter than the neck of the chamber prevents it from holding a fired case. Using sized 9mm is a good idea assuming my dies leave it at .350", but my pistol dies are set up at the same friends house who has the lathe. It would work for set back though regardless of the ID. Actually, now that I think of it, I do have a crusty old set of 357 mag dies here, maybe I'll play with those. Thanks for the idea!

Similar threads

- Replies

- 5

- Views

- 341

- Replies

- 24

- Views

- 2K

- Replies

- 15

- Views

- 552