So I just recently purchased a set of Hornady Matched bushing dies on the exchange. From all I've read on the internet that is the nest step to get my ES and SD down for longer range shooting. Loaded up three groups of 10 rounds each of 6.5 CM using 140ELDM and 41.2 gr. of H4350. Brass is Prime brass. Also started to clean with SS pins and water (if that makes a difference)

Started by measuring about five fired cases. Shoulder measured 1.561

Group 3 was tumbled with corncob media and FL sized with Lee die, trimmed to length using Lee trimmer. Measuring the case to shoulder length was 1.550. Deburred inside and outside of cases, loaded with 41.2gr H4350 trickling last 0.001gr. Bullet seated with Hornady micrometer seater to 2.235 CBTO

Group 2 was cleaned with SS pins and water and sized and loaded as group 3. I di not use and lube when seating bullets but nothing felt hard. I have been told you should either lube bullet or inside of case neck when cleaning with SS pins and water. (?)

Group 1 was SS cleaned but was sizes with Hornady FL bushing die using 0.289 bushing. I adjusted till I got a shoulder bump of 0.003 or 1.558. Neck OD was 0.290 and ID was 0.263. I had used the elliptical expander when sizing and it measure 0.262~0.263. I later read that I might should not have used that expander with the bushing die(?) I did lube bullets some with unique case lube. Just got some on my hands and rubbed bullets a little.

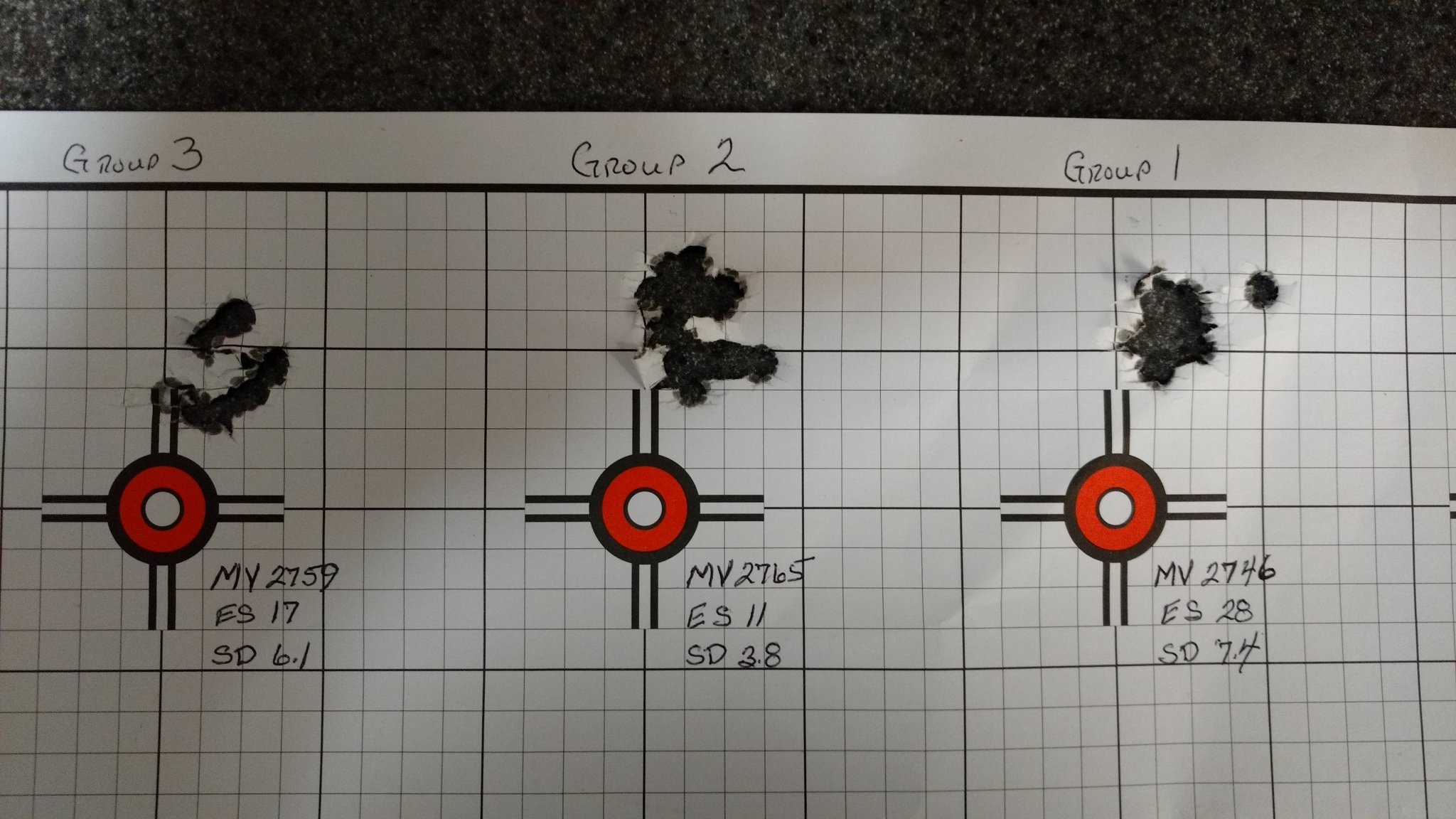

Anyway off to the range I went. These are 10 shot groups shot at 100yrds off bipod and rear squeeze bag. I shot slowly trying to keep barrel cool and had to stop and couple times to let things cool back down. It's East Texas and temp was only about 88, wind was about 8mph from the NE. Target is located almost north of bench.

I was expecting group 1 to have lowest ES and SD but that was not the case and it was the slowest avg. MV of the three.

What am I doing wrong (or right) and where should I go from here? Longer range? Larger groups?

Thanks in advance.

Started by measuring about five fired cases. Shoulder measured 1.561

Group 3 was tumbled with corncob media and FL sized with Lee die, trimmed to length using Lee trimmer. Measuring the case to shoulder length was 1.550. Deburred inside and outside of cases, loaded with 41.2gr H4350 trickling last 0.001gr. Bullet seated with Hornady micrometer seater to 2.235 CBTO

Group 2 was cleaned with SS pins and water and sized and loaded as group 3. I di not use and lube when seating bullets but nothing felt hard. I have been told you should either lube bullet or inside of case neck when cleaning with SS pins and water. (?)

Group 1 was SS cleaned but was sizes with Hornady FL bushing die using 0.289 bushing. I adjusted till I got a shoulder bump of 0.003 or 1.558. Neck OD was 0.290 and ID was 0.263. I had used the elliptical expander when sizing and it measure 0.262~0.263. I later read that I might should not have used that expander with the bushing die(?) I did lube bullets some with unique case lube. Just got some on my hands and rubbed bullets a little.

Anyway off to the range I went. These are 10 shot groups shot at 100yrds off bipod and rear squeeze bag. I shot slowly trying to keep barrel cool and had to stop and couple times to let things cool back down. It's East Texas and temp was only about 88, wind was about 8mph from the NE. Target is located almost north of bench.

I was expecting group 1 to have lowest ES and SD but that was not the case and it was the slowest avg. MV of the three.

What am I doing wrong (or right) and where should I go from here? Longer range? Larger groups?

Thanks in advance.