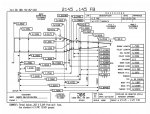

Someone knowledgeable please check to see if i’m reading the attached reamer print correctly. This is for a 6.5 PRC. I’m wanting a tight chamber to minimize working brass. Willing to neck turn to keep proper dimensions. I’ve been told about 12 thou case neck thickness is optimal.

ID of neck = .2989

bullet = .264 + .024 case neck thickness = .288

bullet = .264 + .026 case neck thickness = ..290

Whether I go with 12 thou or 13 thou it appears I will be overworking my brass. I have 500 Lapua cases due the 1st of Feb-2021. I will then fire form cases 3Xs neck sizing only prior to sending off for custom dies.

it appears to me I will be expanding my brass necks 10 thou if I’m reading the print correctly. I’m hoping an expert will tell me if I’m reading the attached print correctly.

My goal is for the chamber to be 3-4 thou over. The rifle is a mag fed bolt. I hear the benchrest shooters use as little a 2 thou over. I‘m picking 3-4 as a compromise to minimize brass working while probably avoiding jams.

I’m headed to my reloading shop with my 1st build to measure chamber ID’s. I know that I’m currently using a .291 bushing while sizing on my ADG brass (no neck turning).

Appreciate knowledgeable feedback. Cross posted.

ID of neck = .2989

bullet = .264 + .024 case neck thickness = .288

bullet = .264 + .026 case neck thickness = ..290

Whether I go with 12 thou or 13 thou it appears I will be overworking my brass. I have 500 Lapua cases due the 1st of Feb-2021. I will then fire form cases 3Xs neck sizing only prior to sending off for custom dies.

it appears to me I will be expanding my brass necks 10 thou if I’m reading the print correctly. I’m hoping an expert will tell me if I’m reading the attached print correctly.

My goal is for the chamber to be 3-4 thou over. The rifle is a mag fed bolt. I hear the benchrest shooters use as little a 2 thou over. I‘m picking 3-4 as a compromise to minimize brass working while probably avoiding jams.

I’m headed to my reloading shop with my 1st build to measure chamber ID’s. I know that I’m currently using a .291 bushing while sizing on my ADG brass (no neck turning).

Appreciate knowledgeable feedback. Cross posted.