I got the threaded flush cups from GrovTech today, so I figured I would do a how to.

First thing is to measure the OD of the cups to see what size drill bit you will need. The GrovTec threaded cups are about .55" so I went with a 5/8" bit (.600")

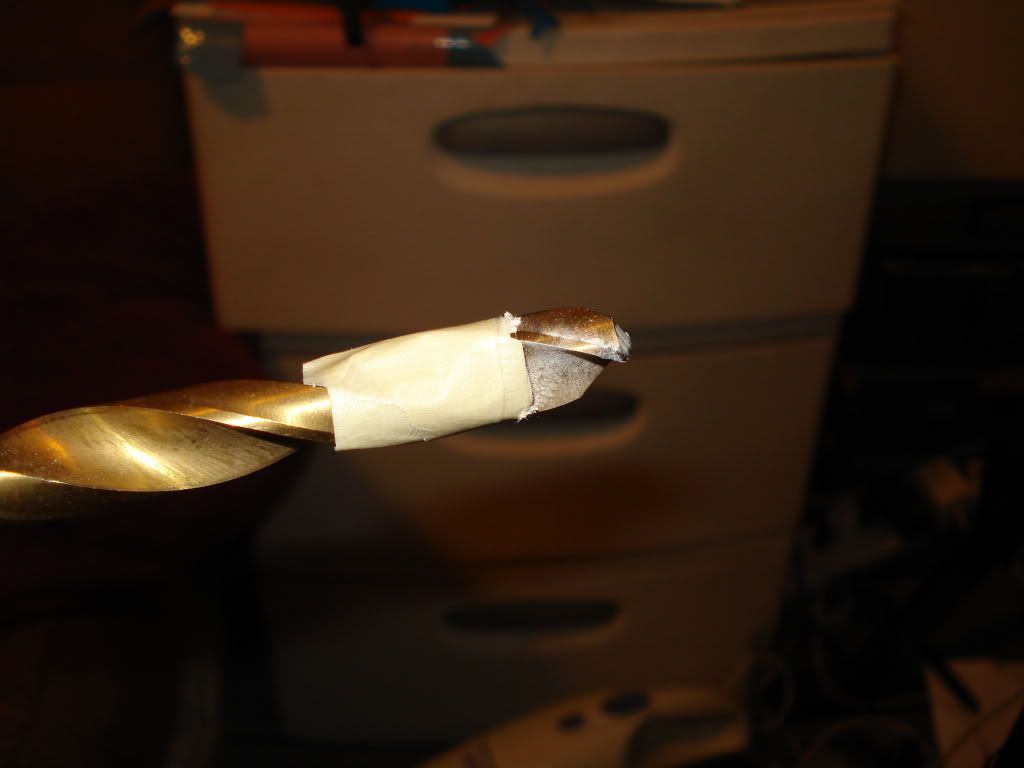

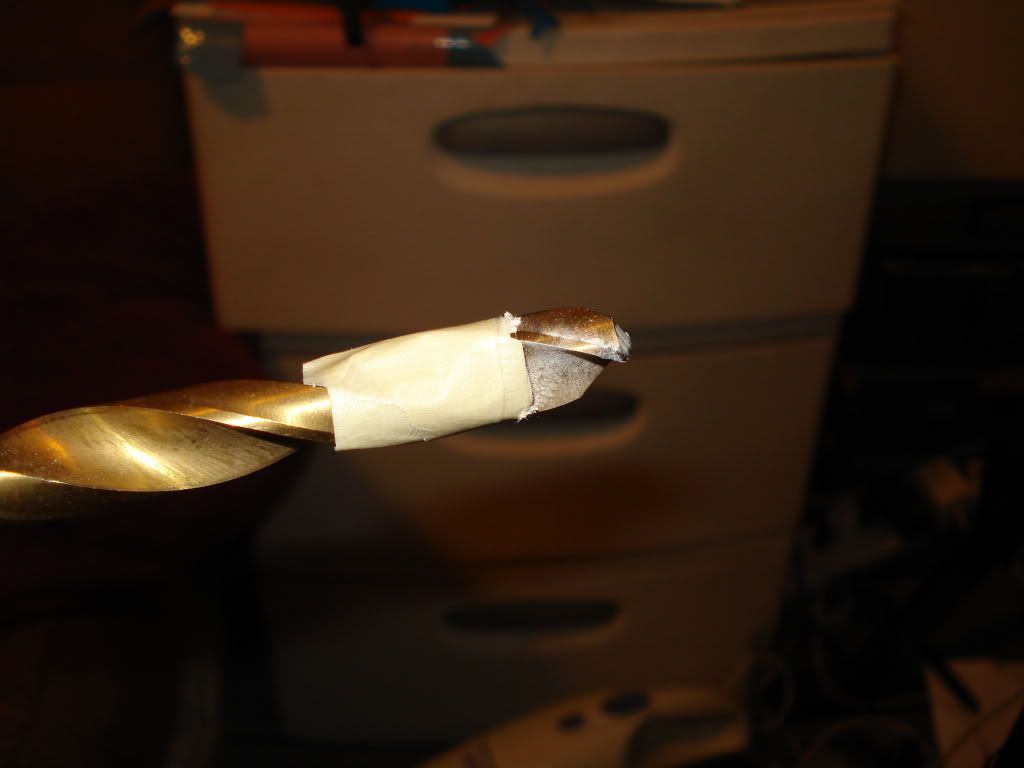

I measured the cups length (1/2") and put tape on the drill bit so I dont drill too deep.

Then I drill the hole, After I drilled the hole and checked to make sure it is deep enough for the cup, I installed a ball mill on my Dremel and made some cuts on the inner wall of the hole all the way around so the bedding can create a mechanical lock and not pull out

Then take a allen wrench that fits the flush cup, and tape it leaving just a tip of the wrench exposed. Make sure you put enough tape on the wrench so it fits the cup snug, this will keep any bedding compound from seeping into the cup.

insert it into the cup

Now mix up whatever bedding compound you are going to be using, I used JB QUICK, you can use anything you want, ie: Steel Bed, Devcon or Marine Tex. Apply the epoxy in the hole making sure you get it on the walls of the hole, and also apply it to the flush cup makeing sure it goes in between the threads to create a good lock.

Insert the cup in the hole until it is flush with the stock, make sure it is flush, if you insert it too deep, your swivel will not seat/lock in properly. Clean all the extra epoxy that oozed out and let it set.

Sice I was using JB QUICK, I didnt have a lot of time to take pics of some of the steps because it sets in 4 minutes.

Here is the finished project

First thing is to measure the OD of the cups to see what size drill bit you will need. The GrovTec threaded cups are about .55" so I went with a 5/8" bit (.600")

I measured the cups length (1/2") and put tape on the drill bit so I dont drill too deep.

Then I drill the hole, After I drilled the hole and checked to make sure it is deep enough for the cup, I installed a ball mill on my Dremel and made some cuts on the inner wall of the hole all the way around so the bedding can create a mechanical lock and not pull out

Then take a allen wrench that fits the flush cup, and tape it leaving just a tip of the wrench exposed. Make sure you put enough tape on the wrench so it fits the cup snug, this will keep any bedding compound from seeping into the cup.

insert it into the cup

Now mix up whatever bedding compound you are going to be using, I used JB QUICK, you can use anything you want, ie: Steel Bed, Devcon or Marine Tex. Apply the epoxy in the hole making sure you get it on the walls of the hole, and also apply it to the flush cup makeing sure it goes in between the threads to create a good lock.

Insert the cup in the hole until it is flush with the stock, make sure it is flush, if you insert it too deep, your swivel will not seat/lock in properly. Clean all the extra epoxy that oozed out and let it set.

Sice I was using JB QUICK, I didnt have a lot of time to take pics of some of the steps because it sets in 4 minutes.

Here is the finished project