Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

Winner! Quick Shot Challenge: What’s the dumbest shooting myth you’ve heard?

View thread

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing in lb torque wrench.

- Thread starter lsm62

- Start date

Re: in lb torque wrench.

Whia makes a decent one that's highly adjustable and Amazon.com carries it for about $60

The one I keep in my range bag/pack is the Borka because I don't need the extra adjustability of the Whia and it is a far less complicated design, less likely to fail in the field.

Whia makes a decent one that's highly adjustable and Amazon.com carries it for about $60

The one I keep in my range bag/pack is the Borka because I don't need the extra adjustability of the Whia and it is a far less complicated design, less likely to fail in the field.

Re: in lb torque wrench.

Check with NAPA. I picked up a nice 1/4 inch ratchet style wrench a couple years ago from them. Don't remember the cost but wasn't cheap.

Check with NAPA. I picked up a nice 1/4 inch ratchet style wrench a couple years ago from them. Don't remember the cost but wasn't cheap.

Re: in lb torque wrench.

The Borka will cover all your rifle needs and is cheaper than buying snap on or other type torque wrenches. Most click type wrenches don't cover all the torque ranges that the Borka does so you would wind up buying at least two different wrenches of any brand to do that task.

The Borka will cover all your rifle needs and is cheaper than buying snap on or other type torque wrenches. Most click type wrenches don't cover all the torque ranges that the Borka does so you would wind up buying at least two different wrenches of any brand to do that task.

Re: in lb torque wrench.

The Borka is an excellent option that is easy to use for all the jobs you listed, it highly compact and portable, and won't break the bank at around $100.

The Borka is an excellent option that is easy to use for all the jobs you listed, it highly compact and portable, and won't break the bank at around $100.

Re: in lb torque wrench.

Brownells has them (Borka). The model with the most settings is like 70 bucks.

Brownells has them (Borka). The model with the most settings is like 70 bucks.

Re: in lb torque wrench.

thanks guys. anyone heard of or used the Wheeler Engineering FAT (Firearm Accurizing Torque) Torque Wrench Screwdriver? at the moment its a toss up between that and the Wiha 28506 TorqueVario-S Torque Screwdriver, 10-50 Inch Pound. would like the borka but these carry more available adjustment.

thanks guys. anyone heard of or used the Wheeler Engineering FAT (Firearm Accurizing Torque) Torque Wrench Screwdriver? at the moment its a toss up between that and the Wiha 28506 TorqueVario-S Torque Screwdriver, 10-50 Inch Pound. would like the borka but these carry more available adjustment.

Re: in lb torque wrench.

Borka Tools ATD-1080-CRS, adjustment range 10-80 inch-lbs. Buy it here

SH members reviews are here

Borka Tools ATD-1080-CRS, adjustment range 10-80 inch-lbs. Buy it here

SH members reviews are here

Re: in lb torque wrench.

I have the FAT Wrench and I'm completely satisfied with it. It does its job and came with all the bits that I have needed so far and a hard case. I am on a budget so I couldnt buy the most expensive wrench out there but the fat wrench gets the job done. However, if you can afford a more expensive one then go for it.

I have the FAT Wrench and I'm completely satisfied with it. It does its job and came with all the bits that I have needed so far and a hard case. I am on a budget so I couldnt buy the most expensive wrench out there but the fat wrench gets the job done. However, if you can afford a more expensive one then go for it.

Re: in lb torque wrench.

I have a Wheeler Fat wrench, 25 and 6 shipping and it is yours. No tips but only used once or twice.

I have a Wheeler Fat wrench, 25 and 6 shipping and it is yours. No tips but only used once or twice.

Re: in lb torque wrench.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: lsm62</div><div class="ubbcode-body">looking for an in/lb torque wrench for scope rings, bottom metal, stock to action and so forth. any suggestions other than snap on? </div></div>

What an original question, to which I for one am glad that it has come up. Topic's like these sure need to be discussed at length to remove any doubt or suspicion.

Thank you, OP, for bringing this up. Maybe we should make a sticky out of it. And while we're at it, flush/delete anything spoken of, which is more than 27 hours old. Obsolete, anyways.

the 'why'

The 'which'

And the 'which'

Another option

Explained a bit

Another option

Or this,

Or or this,

Or maybe even this, if you're not seeing a pattern yet, you should be.

Now, maybe there is someone here who has something new and insightful to add, which will part the seas and reverse the rotation of the earth so that the sun rises in the West.

(little humor there....)

Point is, those links are all (should be?) to THREADS started regarding this topic pretty much unanimously. Maybe perusing can help oneself?

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: lsm62</div><div class="ubbcode-body">looking for an in/lb torque wrench for scope rings, bottom metal, stock to action and so forth. any suggestions other than snap on? </div></div>

What an original question, to which I for one am glad that it has come up. Topic's like these sure need to be discussed at length to remove any doubt or suspicion.

Thank you, OP, for bringing this up. Maybe we should make a sticky out of it. And while we're at it, flush/delete anything spoken of, which is more than 27 hours old. Obsolete, anyways.

the 'why'

The 'which'

And the 'which'

Another option

Explained a bit

Another option

Or this,

Or or this,

Or maybe even this, if you're not seeing a pattern yet, you should be.

Now, maybe there is someone here who has something new and insightful to add, which will part the seas and reverse the rotation of the earth so that the sun rises in the West.

(little humor there....)

Point is, those links are all (should be?) to THREADS started regarding this topic pretty much unanimously. Maybe perusing can help oneself?

Re: in lb torque wrench.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Sean the Nailer</div><div class="ubbcode-body">

Now, maybe there is someone here who has something new and insightful to add, which will part the seas and reverse the rotation of the earth so that the sun rises in the West.

(little humor there....)</div></div>

Ok, Sean, I will give it a try. When I was young, lots of instruments went in for calibration cycles and got tweaked. Now days, instruments are more likely to stay put and unaltered, and we have "check standards" that move around.

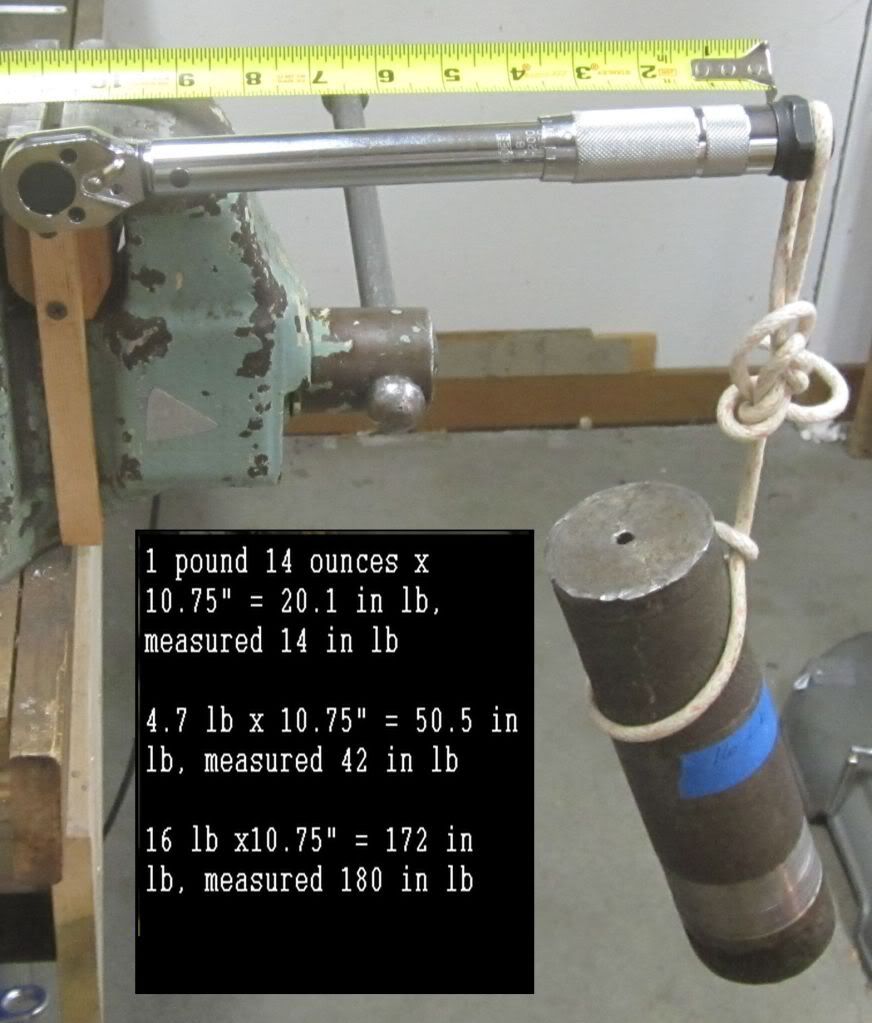

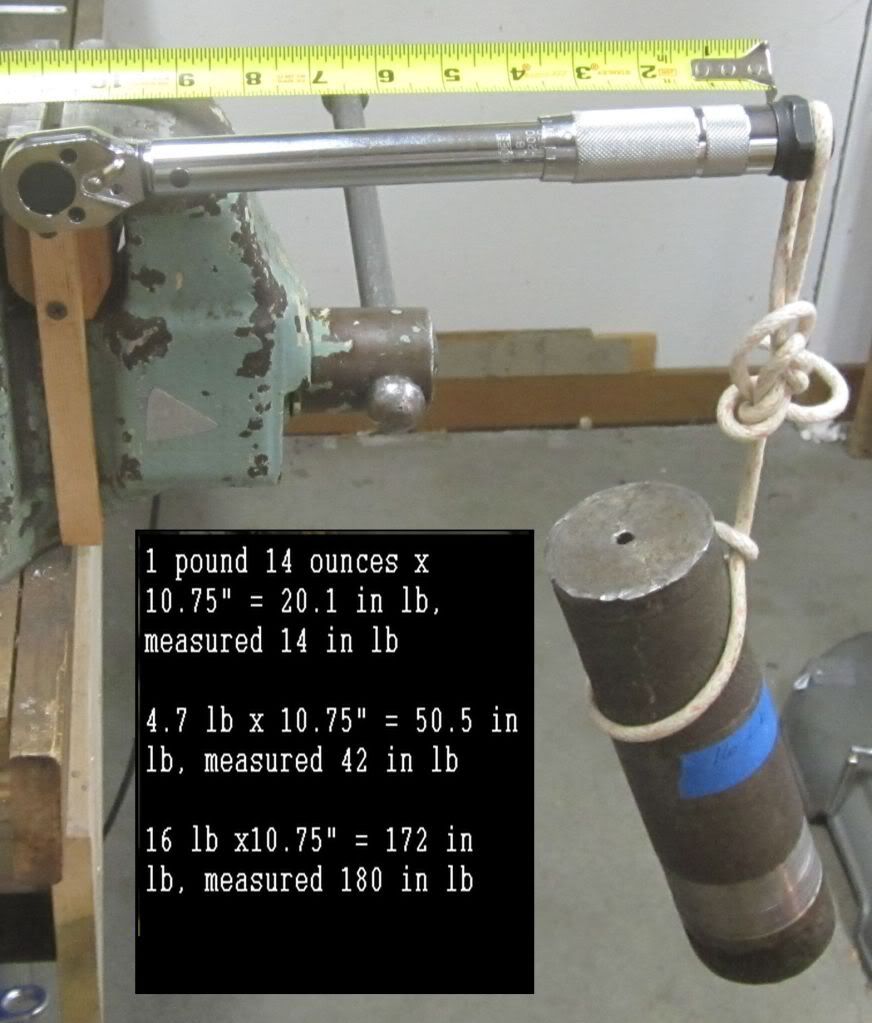

I bought this $20 inch pound torque wrench a couple weeks ago to put on some 10-32 scope mount screws with only three turns of engagement. I calculated the torque at the threshold of yeild for dry, lubed, and waxed threads and the verified those numbers by testing on some .1" thick steel.

http://www.snipershide.com/forum/ubbthre...390#Post2675390

http://www.harborfreight.com/1-4-quarter-inch-drive-click-stop-torque-wrench-2696.html

This a $20 inch pound torque wrench from Harbor freight.

I read the reviews, and some guy broke one after another and they did not work.

I went to the store and was playing with one, and was about to break it when someone pointed out that there is not sound, you have to see it toggle, and it does not toggle far.

http://en.wikipedia.org/wiki/Technical_standard

In this case the "primary standards" were:

Detecto medical beam scale 350 lb

Trimer mail scale 4 lb

Stanley Power Lock tape measure 25'

The "Check standards" were:

1 1/4" wrench that weighed 1 pound 14 ounces

1.5" diameter 9" long round stock steel weighed 4.5 lb

2.75" diameter 9.75" long round stock steel weighed 16 pounds

The distance was 10.75" and I weighed the rope too.

What does it all mean?

a) When I want to apply 20 inch pounds to my scope mounts screws, I had better set that wrench for 14 inch pounds.

b) Then I got all the accuracy needed for $20.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Sean the Nailer</div><div class="ubbcode-body">

Now, maybe there is someone here who has something new and insightful to add, which will part the seas and reverse the rotation of the earth so that the sun rises in the West.

(little humor there....)</div></div>

Ok, Sean, I will give it a try. When I was young, lots of instruments went in for calibration cycles and got tweaked. Now days, instruments are more likely to stay put and unaltered, and we have "check standards" that move around.

I bought this $20 inch pound torque wrench a couple weeks ago to put on some 10-32 scope mount screws with only three turns of engagement. I calculated the torque at the threshold of yeild for dry, lubed, and waxed threads and the verified those numbers by testing on some .1" thick steel.

http://www.snipershide.com/forum/ubbthre...390#Post2675390

http://www.harborfreight.com/1-4-quarter-inch-drive-click-stop-torque-wrench-2696.html

This a $20 inch pound torque wrench from Harbor freight.

I read the reviews, and some guy broke one after another and they did not work.

I went to the store and was playing with one, and was about to break it when someone pointed out that there is not sound, you have to see it toggle, and it does not toggle far.

http://en.wikipedia.org/wiki/Technical_standard

In this case the "primary standards" were:

Detecto medical beam scale 350 lb

Trimer mail scale 4 lb

Stanley Power Lock tape measure 25'

The "Check standards" were:

1 1/4" wrench that weighed 1 pound 14 ounces

1.5" diameter 9" long round stock steel weighed 4.5 lb

2.75" diameter 9.75" long round stock steel weighed 16 pounds

The distance was 10.75" and I weighed the rope too.

What does it all mean?

a) When I want to apply 20 inch pounds to my scope mounts screws, I had better set that wrench for 14 inch pounds.

b) Then I got all the accuracy needed for $20.

Re: in lb torque wrench.

The Borka set up is slick, Beau busted his out when we mounted my USO scope. I was really impressed.

The Borka set up is slick, Beau busted his out when we mounted my USO scope. I was really impressed.

Similar threads

- Replies

- 3

- Views

- 377

- Replies

- 19

- Views

- 914