this one I’ve been using for some time now.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Inch-pound torque wrench

- Thread starter Davesnothere

- Start date

Wheeler non digital has been working well for me. I’d like to get inch pound specific fix it sticks for rings and action screws though. They would take up less space in my range bag.

Have you had them checked? Mine have a sticker on them with a date to recalibrate. Not sure if that's a seekonk thing on general rule for torque wrenches.I've collected 6 different Seekonk Pre-Set wrenches over the years. Also have Wheeler and Magna-tip. I prefer the Seekonk Pre-Set wrenches.

It's not a Seekonk thing. It's an every torque wrench used where it matters thing.Have you had them checked? Mine have a sticker on them with a date to recalibrate. Not sure if that's a seekonk thing on general rule for torque wrenches.

In manufacturing applications, torque tools are calibrated annually and verified against a NIST traceable standard much more frequently. Sometimes as frequently as every shift depending on what they're being used for.

I like the concept of the Wheeler digital fat torque driver but have come to dislike it after using it for a year. Its now shoved in the range bag for i.c.e. and have gone back to the non digital fat wrench.I just ordered the wheeler screwdriver type digital bit-driver torque wrench. I hope it works out. Did you like your wheeler?

Dislikes,

1. Hard rubber grip is hard on your hand at higher torque. Call me a puss idc

2. Finger placement over beep hole makes it nearly impossible to hear the beep so you have to be cautious of that.

3. Battery location sucks. When you need higher torque like above 50inlbs after some use, the hard squeezing on battery cover seems to smush battery in the contacts, causing contact issues, and I now have issues often of it loosing battery contact while torquing and have no idea where the torque value ended up and it resets to 15inlbs and you have to dial it back to whatever you need it set at.

I now wish I had spent that mone on on a set of fix it sticks.

Ymmv

I Have a wheeler and its great for installing optics and whatnot but fixit sticks looks like i could pack it in my range bag a little easier for field use.

The universal fix-it version on T-handle has a ton of stack height, since the limiter is alot taller than sigle-value versions. For the shop I wouldn't recomment a universal. Better to get the singles or a good torque tool with lower stack height.

Field work Fix It Sticks

Home Shop Wiha--lots of sets to fit your needs

www.kctoolco.com

www.kctoolco.com

Home Shop Wiha--lots of sets to fit your needs

Torque Screwdriver Sets by Felo, Wera - KC Tool

Torque screwdriver sets with adjustable torque ranges in newton and inch scale. High quality torque screwdriver sets with calibration certioficate by Wiha and Wera. German Torque screwdrivers.

I looked at that link and maybe I missed it but looks like nothing goes above 55 in/lbs.

There are T handles like this one..lots of other options depends what U need.I looked at that link and maybe I missed it but looks like nothing goes above 55 in/lbs.

TorqueVario ST Plus Adjustable T-handle

TorqueVario Adjustable Torque Control T-handle comes equipped with a soft grip handle for comfort and control. Create an adjustable torque screwdriver in inch pounds with Wiha TorqueVario Torque Handle to match your specific application's torque range (44.3 - 123.9 In/lbs). The TorqueVario...

TorqueVario Adjustable Torque Control T-handle 44.3 - 123.9 In/Lbs. 5-14Nm

I just got done shopping for one to do it all. It's too expensive to get t-handles for every job and most of the high end torque wrenches that are adjustable don't come in the appropriate range I need --not low enough or not high enough, always something. And I couldn't find a good t-handle that's adjustable.

There are lots of good ones, the Seekonk I have for the DTA is great, others like CDI. But those are expensive. A lot of what you're paying for is the certification.

The fix it sticks looked handy but didn't go high enough to barrel an MRAD. They also have like a 10%+ error.

I ended up getting a "Tekton" on Amazon for less than $50 --it has a 3-4% error (same or better than most of the ones recommended on here, it's actually a good number) and it's range is 10-150 IIRC. It's small enough to fit in field kit and it works for all optics and barrels I deal with.

Why pay more for higher error? Even if wear and tear makes this one less accurate it'll still be better than many out there and cheap enough to replace.

There are lots of good ones, the Seekonk I have for the DTA is great, others like CDI. But those are expensive. A lot of what you're paying for is the certification.

The fix it sticks looked handy but didn't go high enough to barrel an MRAD. They also have like a 10%+ error.

I ended up getting a "Tekton" on Amazon for less than $50 --it has a 3-4% error (same or better than most of the ones recommended on here, it's actually a good number) and it's range is 10-150 IIRC. It's small enough to fit in field kit and it works for all optics and barrels I deal with.

Why pay more for higher error? Even if wear and tear makes this one less accurate it'll still be better than many out there and cheap enough to replace.

It's not a Seekonk thing. It's an every torque wrench used where it matters thing.

In manufacturing applications, torque tools are calibrated annually and verified against a NIST traceable standard much more frequently. Sometimes as frequently as every shift depending on what they're being used for.

At work I have to get my 2 Snap-On techangle wrenches cal'd in house every 6 months. At home for my amateur lifestyle and occasional scope mounting/hobbying, my wheeler fat wrench does just fine.

The fix it sticks looked handy but didn't go high enough to barrel an MRAD. They also have like a 10%+ error.

Fix it sticks do not have a 10% error. Where did you see that? Are you talking about the limiters or the all in one?

A test from a few years ago testing some torque wrenches.

Torque Wrenches for Precision Shooting

Thanks for the write up. I too don't really care for the borka kits. We stock the fix-it-sticks deluxe kits now. The torque limiters are quite good, in operation at least. I'll send you out a kit and you can check it out.

+/- 6% Accuracy is in line with most rotational driver styles ("screwdrivers")

See this page for accuracy comparables from Hazet in .DE

www.hazet.de

www.hazet.de

Good tools are 2-4% is typical/best in class

Screwdriver styles 5-6% is typical

Note that smaller instruments are harder to do well, this applies inch/pounds ranges being discussed (1-6nm)

www.hazet.de

www.hazet.de

See this page for accuracy comparables from Hazet in .DE

Torque wrench

www.hazet.de

www.hazet.de

Good tools are 2-4% is typical/best in class

Screwdriver styles 5-6% is typical

Note that smaller instruments are harder to do well, this applies inch/pounds ranges being discussed (1-6nm)

HAZET-WERK - Hermann Zerver GmbH & Co. KG

www.hazet.de

www.hazet.de

Last edited:

All-in-one has an error rate of +/- 10% while the limiters have a +/- error rate of 6%

according to their posted info

That is why I asked.

PSA.......I listed above a variety of torque wrenches I use for various tasks because:

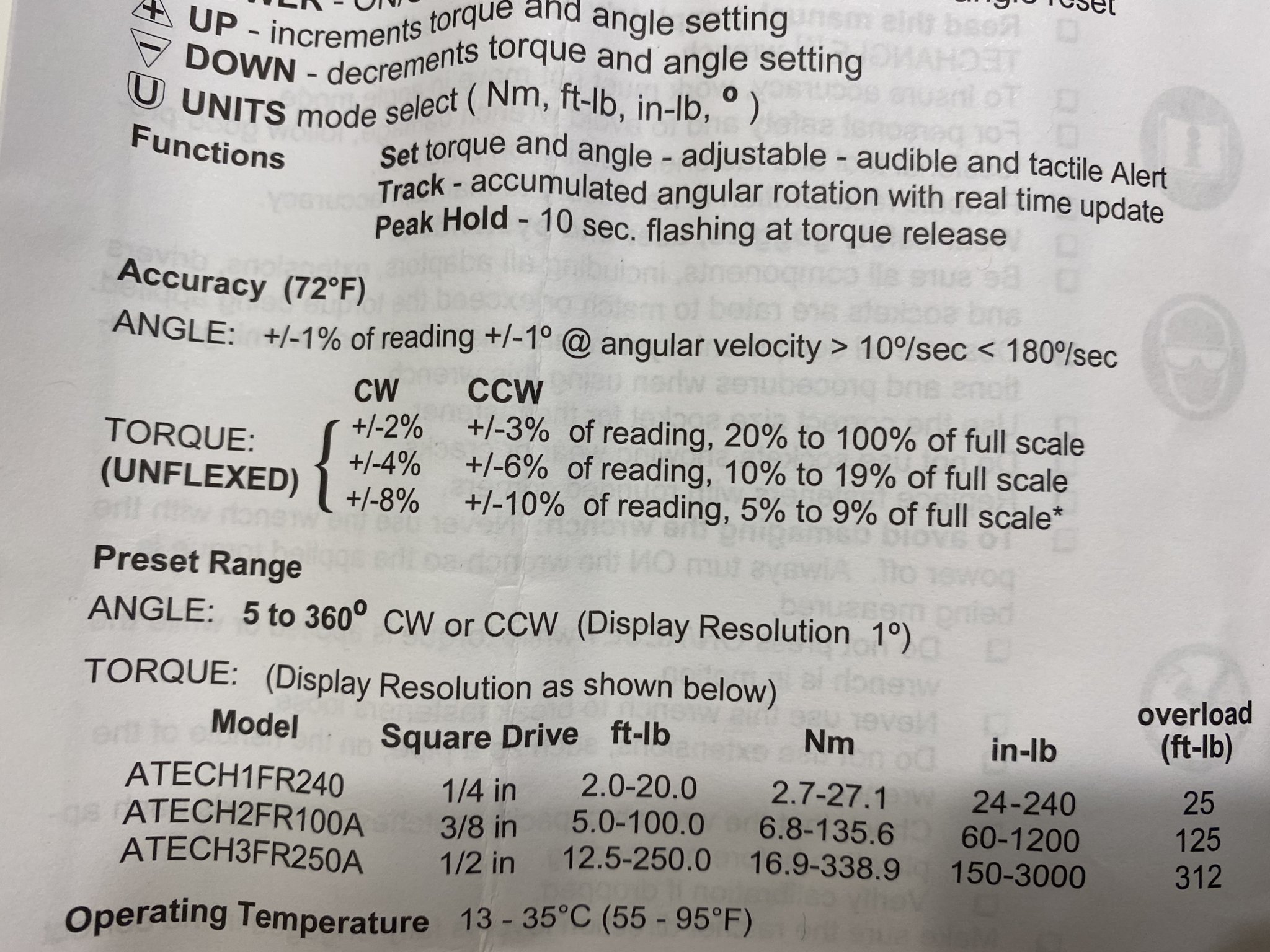

1. The "accuracy" of the tool depends often on the magnitude of tool range-of-use (0-20 v. 0-120 in-lbs) as well as ambient temperature (which is probably a moot point for indoor assembly), and the sector of the tool range that you will be using it at, i.e. lower 10%, mid 40%, or upper 10% of the tools range. For example the Snap-On that has a range of 0-120 in-lbs has a different accuracy rating depending on which range of use AND whether one is using a right / left hand threaded fastener (see photo). A 10% error rating on a 120 in--lb scale is ~12 in-pounds......more than than should be used total for most common pistol grip screw installations!

2. One should know that most often the torque tool is appropriate for a left hand thread installation as well as a more common right thread installation; no so with Fix-It sticks which have no left hand thread torque option. Snap-On torque tools can be used to torque both right / left hand fasteners.

3. Whenever practical use the torque tool that has the smallest range of use that is useful for your specific application.

1. The "accuracy" of the tool depends often on the magnitude of tool range-of-use (0-20 v. 0-120 in-lbs) as well as ambient temperature (which is probably a moot point for indoor assembly), and the sector of the tool range that you will be using it at, i.e. lower 10%, mid 40%, or upper 10% of the tools range. For example the Snap-On that has a range of 0-120 in-lbs has a different accuracy rating depending on which range of use AND whether one is using a right / left hand threaded fastener (see photo). A 10% error rating on a 120 in--lb scale is ~12 in-pounds......more than than should be used total for most common pistol grip screw installations!

2. One should know that most often the torque tool is appropriate for a left hand thread installation as well as a more common right thread installation; no so with Fix-It sticks which have no left hand thread torque option. Snap-On torque tools can be used to torque both right / left hand fasteners.

3. Whenever practical use the torque tool that has the smallest range of use that is useful for your specific application.

Fix it sticks do not have a 10% error. Where did you see that? Are you talking about the limiters or the all in one?

A test from a few years ago testing some torque wrenches.

Torque Wrenches for Precision Shooting

Thanks for the write up. I too don't really care for the borka kits. We stock the fix-it-sticks deluxe kits now. The torque limiters are quite good, in operation at least. I'll send you out a kit and you can check it out.forums.gunhive.com

Yeah, the adj. one.

Here's what I got:

https://www.amazon.com/TEKTON-TRQ21101-4-Inch-Dual-Direction-1-1-16-9/dp/B01M12284X

10-150 inch/lbs, dual direction, 4% accuracy forward (not 3% like I thought) 6% reverse, 8.8" long, $43. Absolutely perfect for a field kit, fine for the shop too but if you mount scopes daily it may behoove you to get a better tool. I don't, I mount a few a year during a busy year I'm sure most are fine for swapping barrels, etc.

I looked and I wasn't able to find a similar, higher quality wrench with these specs.

Well, you could always go with this. It is +/- 2% clockwise and +/- 3% counterclockwise. Control angle accuracy to +/- 1% of reading +/- 1 degree. The link shows it as a 1/2 drive but the item is a 1/4 drive 12-240 in.lbs

CDI Torque 2503CASG 1/2 Drive Computorq Steel Grip Electronic Wrench - - Amazon.com

If you want more choices, start on page 98, they have several

CDI Torque Tools CDI Torque Tools (bluetoad.com)

CDI Torque 2503CASG 1/2 Drive Computorq Steel Grip Electronic Wrench - - Amazon.com

If you want more choices, start on page 98, they have several

CDI Torque Tools CDI Torque Tools (bluetoad.com)

I have that 1/4" tekton clicker. It blows compared to a CDI or Precision Instruments. It hardly clicks and IMO is very easy to go over your target torque spec. YMMV.I just got done shopping for one to do it all. It's too expensive to get t-handles for every job and most of the high end torque wrenches that are adjustable don't come in the appropriate range I need --not low enough or not high enough, always something. And I couldn't find a good t-handle that's adjustable.

There are lots of good ones, the Seekonk I have for the DTA is great, others like CDI. But those are expensive. A lot of what you're paying for is the certification.

The fix it sticks looked handy but didn't go high enough to barrel an MRAD. They also have like a 10%+ error.

I ended up getting a "Tekton" on Amazon for less than $50 --it has a 3-4% error (same or better than most of the ones recommended on here, it's actually a good number) and it's range is 10-150 IIRC. It's small enough to fit in field kit and it works for all optics and barrels I deal with.

Why pay more for higher error? Even if wear and tear makes this one less accurate it'll still be better than many out there and cheap enough to replace.

Just saw your second post. That range is way too wide for precision work. A torque wrench of any kind is going to be most accurate in the middle of its range. IIRC they make one that goes up to 75 inch lbs, at the very least I'd return it for that one.

Recently had a caveman/bloke at rifle club bring up some issues with his rifle.

Vibrations, unable to zero consistently.

Yup, him no use torque tools.

Him make hand adjustments.

Him say no need for tools.

I asked him, if you don't need to torque the fittings....why the fuck are there torque settings in the manuals and spec sheets?

He agreed to let someone torque up his rifle and scope... et voila!

Rifle does okay now.

Vibrations, unable to zero consistently.

Yup, him no use torque tools.

Him make hand adjustments.

Him say no need for tools.

I asked him, if you don't need to torque the fittings....why the fuck are there torque settings in the manuals and spec sheets?

He agreed to let someone torque up his rifle and scope... et voila!

Rifle does okay now.

Similar threads

- Replies

- 4

- Views

- 197

- Replies

- 3

- Views

- 416

- Replies

- 4

- Views

- 1K

- Replies

- 14

- Views

- 851