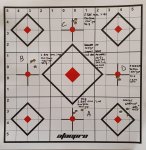

I plan to work towards a ladder test for my 6.5CM loads but wont be starting with the bullet in the lands because the bullet would barely be in the case. So I decided to follow Bergers advice and try several different seating depths 40 Thou apart, they are the groups A,B,C,D in the attached pic. corresponding to jumps of 210/170/130/90 Thou. At 90 thou the rounds are at an OAL of 2.925" and are on the verge of magazine feeding issues so shorter jumps are not viable. At 90 Thou there is .1265" of bearing surface engaged in the neck.

Now onto those results ... can anyone offer any advice as to why the 90 Thou group shot in a completely different position compared to all the other groups? The group size at 90 Thou and 130 Thou both were reasonably tight at .270" (100m). I'm trying to decide whether I should proceed with load development at 90 Thou Jump or 130 Thou jump. I previously did a charge weight test to arrive at 42.4 Gr powder as a basis for this test but I will revisit the charge weight via a ladder test in the near term.

Now onto those results ... can anyone offer any advice as to why the 90 Thou group shot in a completely different position compared to all the other groups? The group size at 90 Thou and 130 Thou both were reasonably tight at .270" (100m). I'm trying to decide whether I should proceed with load development at 90 Thou Jump or 130 Thou jump. I previously did a charge weight test to arrive at 42.4 Gr powder as a basis for this test but I will revisit the charge weight via a ladder test in the near term.