Re: LA Bounty bolt fixture

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 300sniper</div><div class="ubbcode-body">

edit: if i remember correctly from back when i drew it up in cad, assuming about .006" of bolt body to receiver clearance, if the rear of the bolt is pushed to one extreme and the front of the bolt the other, there was less than .00015" of gap between the extreme end of one lug.

</div></div>

Close, but you have one too many Zero's in there. I did some tests and so did Greg Tannel a while back (can be seen in his bolt sleeving video) about this very topic.

Like you mentioned, if the front of the bolt was resting on the lower part of the action (which it may with the back of the bolt pushed up) and the back of the bolt raised the front of the lug will walk forward from less than .001 to slightly under .002" depending on how much clearance is around the bolt.

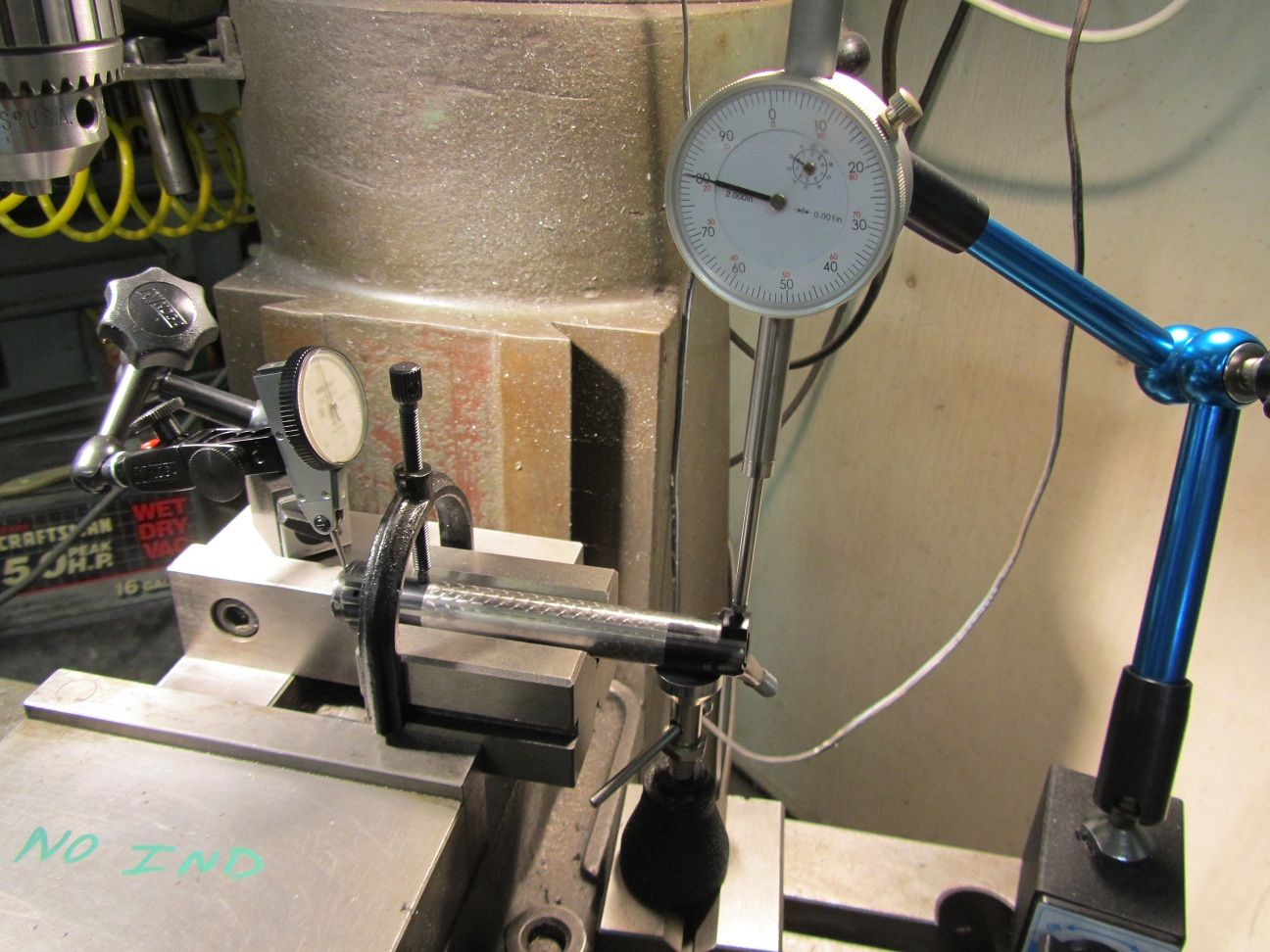

Here is a picture of what I did and here is the results I came up with.

With a Remington 700 Long Action bolt.

Back of bolt raised up.... Front top lug advanced forward...

.005 up = .001 forward

.008 up = .0013 forward

.010 up = .0016 forward

.012 up = .0018 forward

Remington Short Action bolt

.005 up = .0007 forward

.008 up = .0011 forward

.010 up = .0013 forward

.012 up = .0015 forward

As you can see from the data with the rear of the bolt body about .008 up the front of the lug goes roughly .001 forward. I know that is not a lot but when you have 60,000 PSI in the chamber pushing back the bolt face, your top lug moves back under that pressure until it contacts the internal lugs of the action while your bottom lug is essentially the pivot point. This is just another variable in the equation that is eliminated by sleeving, grinding bumps or have a tight bolt fit will correct. What makes an action really accurate...keeping the bolt tight and locked up before and during ignition.

I think we all have built actions that shoot really well with just a straight trued action and bolt with plenty of clearance. But when its your job to do it every time, your suggestion for the customer is always going to be to deal with the bolt one way or another to tighten it up.

Give Gordy Gritters, Jim Borden, William Roscoe, Mike Bush or Greg Tannel a call and see what they think. Heck, I bet the GAP Templar has a bolt clearance around or less than .003. They seem to have the formula down for building very accurate rifles for quite some time now and their rifles are all over the world in real life scenarios with out any hitches.

Bottom line, your main accuracy is coming from your barrel, crown, chamber/throat and barrel shoulder junction. Everything else seems to be the icing on the cake and helping deliver the accuracy every time.

Mark