Hi Everyone,

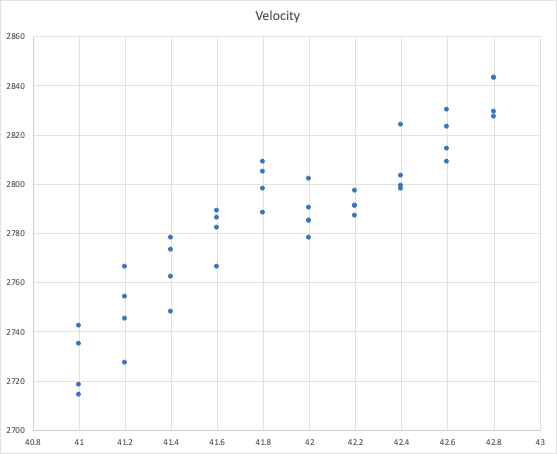

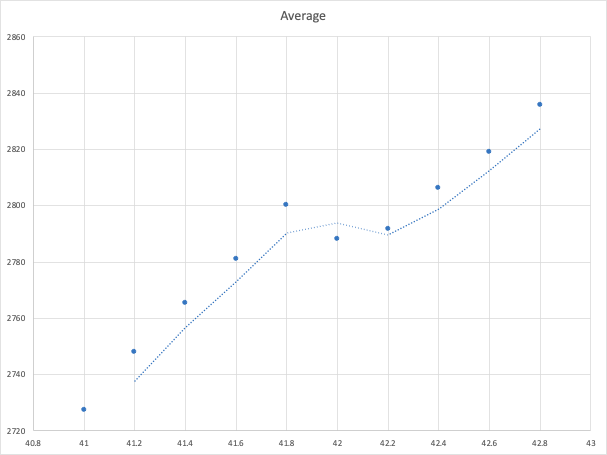

I recently completed my load development for a new barrel and wanted to check if I am on the right track with picking 42.3 grains as my node. That group shot well, but I noticed I might need to bump the shoulder back .001 as the rounds are slightly tight on close as I used brass previously fired from another barrel. Will bumping the shoulder back change the case capacity and require me to verify my node again, or can I continue to send it?

Lapua 6.5 CM Brass

Barnes 6.5 127 GN LRXBT

H4350

CCI 450

I appreciate everyone's advice and feedback!

Cheers!

I recently completed my load development for a new barrel and wanted to check if I am on the right track with picking 42.3 grains as my node. That group shot well, but I noticed I might need to bump the shoulder back .001 as the rounds are slightly tight on close as I used brass previously fired from another barrel. Will bumping the shoulder back change the case capacity and require me to verify my node again, or can I continue to send it?

Lapua 6.5 CM Brass

Barnes 6.5 127 GN LRXBT

H4350

CCI 450

I appreciate everyone's advice and feedback!

Cheers!