I swear I've seen this before, but can't find pics or info on it.

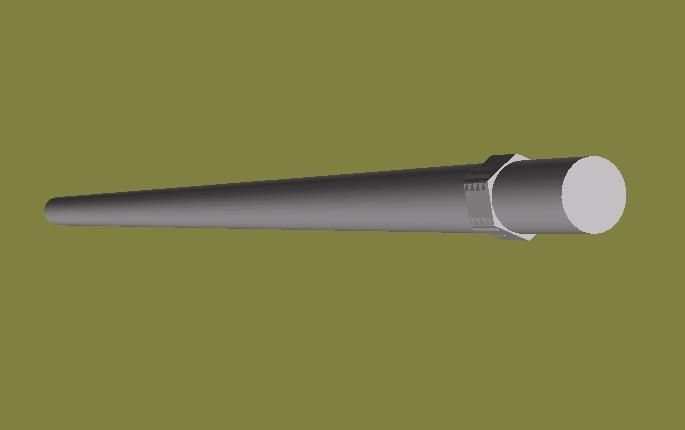

Say I want a Surgeon switch barrel and don't want to use a barrel vise. Maybe I'll just leave it in the AICS when changing barrels and clamp that in a regular vise. Can a barrel be machined just forward of the action so that it has two flat sides and an open end wrench can simply be used to snug it up? Maybe just make some witness marks so you tighten to the same place every time?

I'm sure I'm over simplifying it and I'm missing something....or it's just a terrible idea. Any experiences doing this?

Say I want a Surgeon switch barrel and don't want to use a barrel vise. Maybe I'll just leave it in the AICS when changing barrels and clamp that in a regular vise. Can a barrel be machined just forward of the action so that it has two flat sides and an open end wrench can simply be used to snug it up? Maybe just make some witness marks so you tighten to the same place every time?

I'm sure I'm over simplifying it and I'm missing something....or it's just a terrible idea. Any experiences doing this?