Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

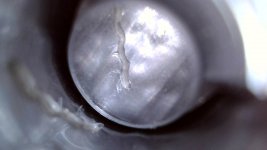

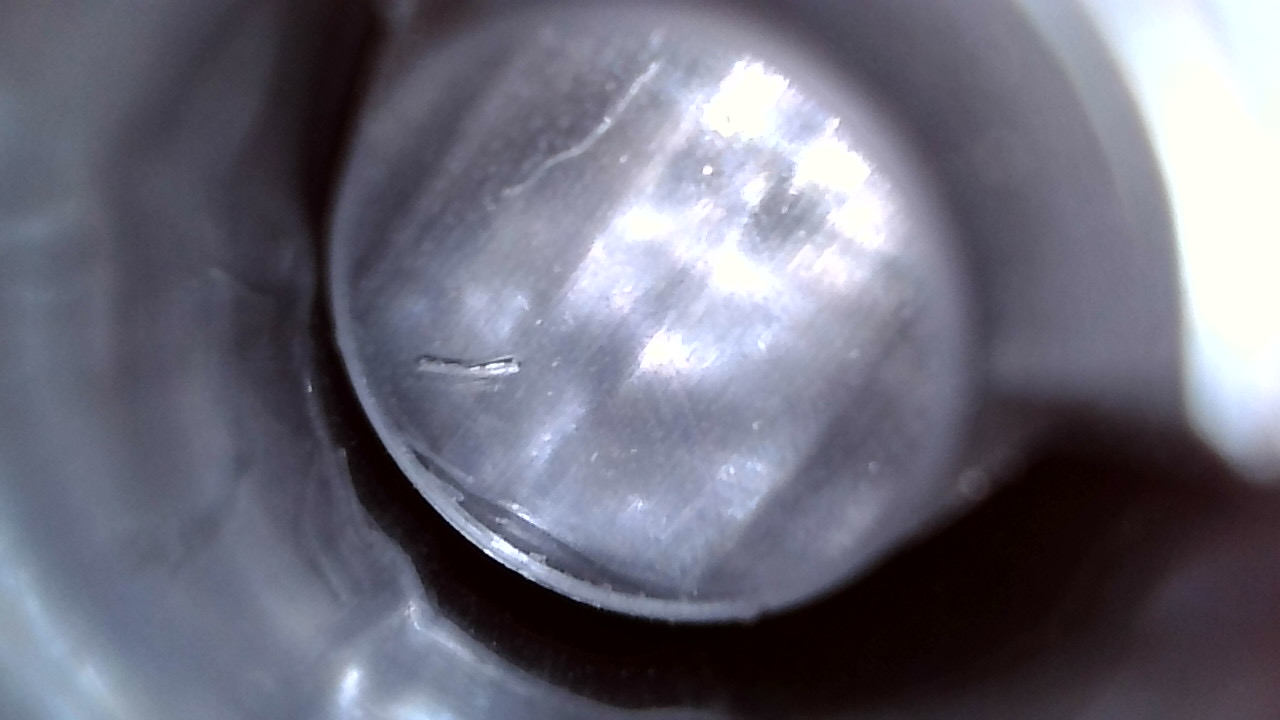

Marks on inside od 22lr barrel

- Thread starter scotty2hotty

- Start date

A bore scope does not tell you how a barrel shoots. I have seen barrels that looks bad, but shoot great, and barrel that looks great and shoot so so.

shoots good .4’sat 50 yrdsWhere are they located in the barrel!

How does it shoot now?

If ya' don't know ya' ask.

That's how ya' learn, right?

Look carefully, can you see it in two places?

In the mirror and direct from the lens looking forward?

That's a piece of cotton patch.

It's barely visible at the bottom left of the mirror on the wall of the bore

but easily identifiable as another strand of cotton in the mirror, once you've had someone explain it.

Borescopes are handy tools, keeping mine.

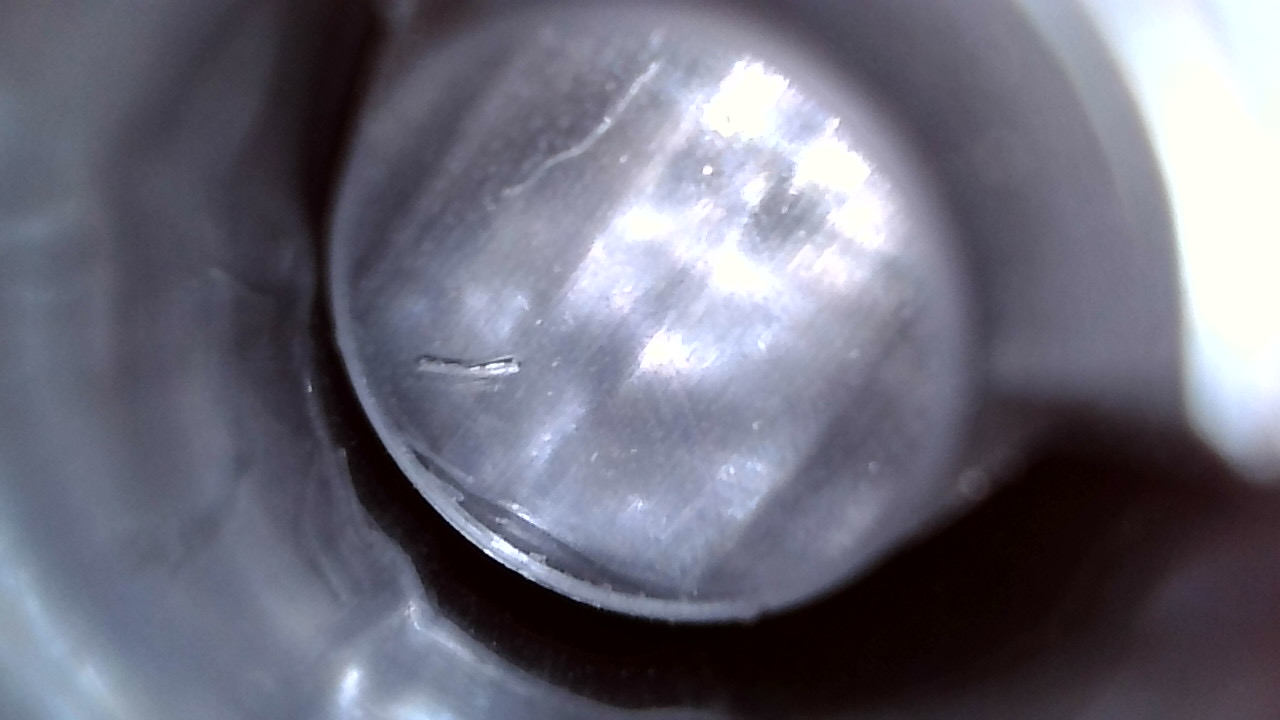

Ummmmm....is that bore a bit smoother than it should be?

Could be just at the start of the leade.

I don't see much in the way of rifling....

That's how ya' learn, right?

Look carefully, can you see it in two places?

In the mirror and direct from the lens looking forward?

That's a piece of cotton patch.

It's barely visible at the bottom left of the mirror on the wall of the bore

but easily identifiable as another strand of cotton in the mirror, once you've had someone explain it.

Borescopes are handy tools, keeping mine.

Ummmmm....is that bore a bit smoother than it should be?

Could be just at the start of the leade.

I don't see much in the way of rifling....

Last edited:

If ya' don't know ya' ask.

That's how ya' learn, right?

Look carefully, can you see it in two places?

In the mirror and direct from the lens looking forward?

That's a piece of cotton patch.

It's barely visible at the bottom left of the mirror on the wall of the bore

but easily identifiable as another strand of cotton in the mirror, once you've had someone explain it.

Borescopes are handy tools, keeping mine.

If ya' don't know ya' ask.

That's how ya' learn, right?

Look carefully, can you see it in two places?

In the mirror and direct from the lens looking forward?

That's a piece of cotton patch.

It's barely visible at the bottom left of the mirror on the wall of the bore

but easily identifiable as another strand of cotton in the mirror, once you've had someone explain it.

Borescopes are handy tools, keeping mine.

Ummmmm....is that bore a bit smoother than it should be?

Could be just at the start of the leade.

I don't see much in the way of rifling....

Thanks just bought the bore scope 2nd time using it, I swore it didn't even look like a fiber I was trying to find it again for 2 hours

Thanks just bought the bore scope 2nd time using it, I swore it didn't even look like a fiber I was trying to find it again for 2 hours

2 hours you could have been shooting the rifle that shoots good. Lock the bore scope up.

I agree, I looked through a scope at the bore of my Savage MK II, that is EXTREMELY accurate, and was frightened out of my wits(LOL)2 hours you could have been shooting the rifle that shoots good. Lock the bore scope up.

Why would anyone want a borescope?

Will it make y'er rifle more accurate? Not really.

Will it improve ammunition quality? No.

What use is it?

It's a diagnostic tool. It allows the inspection of the bore

when looking for possible reasons for poor results.

Check for carbon ring? Yes.

Check for burrs in the leade? Yes.

Check for lead deposits or copper fouling? Yes.

Check for throat erosion or rifling wear? Yes.

Check for cracks or fissures caused by hammer forging? Yes.

It allows you to inspect for problems and to increase y'er knowledge

of what occurs inside the bore as barrel wear accumulates.

Y'all do know rimfire cartridges eat away at the rifling with every shot fired.

It can actually be watched and documented over time. For that a borescope is handy.

I find it useful.

Will it make y'er rifle more accurate? Not really.

Will it improve ammunition quality? No.

What use is it?

It's a diagnostic tool. It allows the inspection of the bore

when looking for possible reasons for poor results.

Check for carbon ring? Yes.

Check for burrs in the leade? Yes.

Check for lead deposits or copper fouling? Yes.

Check for throat erosion or rifling wear? Yes.

Check for cracks or fissures caused by hammer forging? Yes.

It allows you to inspect for problems and to increase y'er knowledge

of what occurs inside the bore as barrel wear accumulates.

Y'all do know rimfire cartridges eat away at the rifling with every shot fired.

It can actually be watched and documented over time. For that a borescope is handy.

I find it useful.

Whenever a bore scope pic is posted it is inevitable that the peanut gallery will come out of the woodwork and sing “throw it away” in three part harmony. And it is as snarky and as empty of intelligence the first time it’s said as every time thereafter.Why would anyone want a borescope?

Will it make y'er rifle more accurate? Not really.

Will it improve ammunition quality? No.

What use is it?

It's a diagnostic tool. It allows the inspection of the bore

when looking for possible reasons for poor results.

Check for carbon ring? Yes.

Check for burrs in the leade? Yes.

Check for lead deposits or copper fouling? Yes.

Check for throat erosion or rifling wear? Yes.

Check for cracks or fissures caused by hammer forging? Yes.

It allows you to inspect for problems and to increase y'er knowledge

of what occurs inside the bore as barrel wear accumulates.

Y'all do know rimfire cartridges eat away at the rifling with every shot fired.

It can actually be watched and documented over time. For that a borescope is handy.

I find it useful.

And yes, that is a very good list of valid uses of a bore scope. Also pretty handy for checking baffles when you shoot your can 50 yds down range (ask me how I know…lol).

And also agree….how the fuck is someone supposed to learn about what is and is not valid insights from bore scope examination except by using one and asking. I’m pretty sure the knowledge didn’t spring to fullness in some minds in their sleep.

That kind of reply…as empty of any actual content or thought…is as inevitable as the sun rising in the east every morning….for at least the next billion years! Haha.

Why would anyone want a borescope?

Will it make y'er rifle more accurate? Not really.

Will it improve ammunition quality? No.

What use is it?

It's a diagnostic tool. It allows the inspection of the bore

when looking for possible reasons for poor results.

Check for carbon ring? Yes.

Check for burrs in the leade? Yes.

Check for lead deposits or copper fouling? Yes.

Check for throat erosion or rifling wear? Yes.

Check for cracks or fissures caused by hammer forging? Yes.

It allows you to inspect for problems and to increase y'er knowledge

of what occurs inside the bore as barrel wear accumulates.

Y'all do know rimfire cartridges eat away at the rifling with every shot fired.

It can actually be watched and documented over time. For that a borescope is handy.

I find it useful.

Yup those .22s eat barrels. Only about 800 rounds and you have to rebarrel the way they eat away the rifling. Lol

Rob, ya'need to talk to lowlight about getting us a [sarcasm font].

I'm tracking wear in a CZ 455 factory barrel.

It was pointed out it hasn't been done to back up claims of improved accuracy

after sending 2 bricks downrange to polish the rifling in a new 22lr barrel.

I'm doing just that. You can see the difference after 1000 shots.

I'm almost at 2000 shots and will be documenting the changes again.

I'm easily entertained.

I'm tracking wear in a CZ 455 factory barrel.

It was pointed out it hasn't been done to back up claims of improved accuracy

after sending 2 bricks downrange to polish the rifling in a new 22lr barrel.

I'm doing just that. You can see the difference after 1000 shots.

I'm almost at 2000 shots and will be documenting the changes again.

I'm easily entertained.

Yes, you are right. It seems that lead is harder than steel, and rapidly wears out the bore(LOL) I do agree however, there is a use for borescope’s when accuracy degrades in center fire firearms.Yup those .22s eat barrels. Only about 800 rounds and you have to rebarrel the way they eat away the rifling. Lol

Accuracy degrades then give it a good cleaning. If your round count is high, you should be keeping a round count book, then barrel is probably going and time for a new one. Not rocket science.

How the hell have I done this for 30 years and never had one of these wonder tools that has all the answers! LOL

How the hell have I done this for 30 years and never had one of these wonder tools that has all the answers! LOL

I can answer that.

30 years ago there were no usb borescopes.

The dang things were expensive as heck and only gunsmiths and airframe techs needed them.

Now you can buy one for less than a brick of cheap 22lr and so why not?

Another toy for the work bench and it's fun to mess with.

30 years ago there were no usb borescopes.

The dang things were expensive as heck and only gunsmiths and airframe techs needed them.

Now you can buy one for less than a brick of cheap 22lr and so why not?

Another toy for the work bench and it's fun to mess with.

I can answer that.

30 years ago there were no usb borescopes.

The dang things were expensive as heck and only gunsmiths and airframe techs needed them.

Now you can buy one for less than a brick of cheap 22lr and so why not?

Another toy for the work bench and it's fun to mess with.

Not really the answer as I still don't have a need for one. Nothing to do with cost. No need for another toy to take up space.

I wouldn't have bought one either Rob.

During a discussion of 22lr barrel break in it was pointed out I had no proof of barrel wear.

How could a lead 22lr cause wear to a steel barrel? How could I verify the process?

Needed a cheap borescope to document wear over time. It's been educational.

During a discussion of 22lr barrel break in it was pointed out I had no proof of barrel wear.

How could a lead 22lr cause wear to a steel barrel? How could I verify the process?

Needed a cheap borescope to document wear over time. It's been educational.

Lead wear on the barrel would probably be very minimal but the lead bullet getting embedded with carbon particles and the carbon

wearing the barrel, that I would believe.

wearing the barrel, that I would believe.

The particle that acts as an abrasive is silica.

Basically crushed glass that generates the spark that ignites the primer when impacted.

Part of the primer mix found in all rimfire cartridges.

It causes that fine linear scratch pattern seen in the rifling.

Silica is harder than steel and is blown into the bore with every shot fired.

Each succeeding shot pushes the silica along the rifling and acts as a polishing agent.

I can see in a series of images taken at 100 shot intervals that the new barrel tool marks

are being worn smooth. Good thing my OCD is willing to play with these long term projects.

Basically crushed glass that generates the spark that ignites the primer when impacted.

Part of the primer mix found in all rimfire cartridges.

It causes that fine linear scratch pattern seen in the rifling.

Silica is harder than steel and is blown into the bore with every shot fired.

Each succeeding shot pushes the silica along the rifling and acts as a polishing agent.

I can see in a series of images taken at 100 shot intervals that the new barrel tool marks

are being worn smooth. Good thing my OCD is willing to play with these long term projects.

The particle that acts as an abrasive is silica.

Basically crushed glass that generates the spark that ignites the primer when impacted.

Part of the primer mix found in all rimfire cartridges.

It causes that fine linear scratch pattern seen in the rifling.

Silica is harder than steel and is blown into the bore with every shot fired.

Each succeeding shot pushes the silica along the rifling and acts as a polishing agent.

I can see in a series of images taken at 100 shot intervals that the new barrel tool marks

are being worn smooth. Good thing my OCD is willing to play with these long term projects.

Justin's description about what can cause wear on a 22lr bore is correct. Yes, it is a very slow process. But, if you shoot weekly matches you will burn through lots of ammo thru the same rifle. In the 2020 season, I fired over 20,000 rds of 22lr, most of which went thru the same rifle. The rifle still shoots fine but you can see the wear. I ran about half that thru a CZ in 2021 and it started to no longer shoot well. Bore issues were the main culprit. That fine abrasive embeds into the lead projectile and scrapes all the way down the bore.

JG26_Irish,Justin's description about what can cause wear on a 22lr bore is correct. Yes, it is a very slow process. But, if you shoot weekly matches you will burn through lots of ammo thru the same rifle. In the 2020 season, I fired over 20,000 rds of 22lr, most of which went thru the same rifle. The rifle still shoots fine but you can see the wear. I ran about half that thru a CZ in 2021 and it started to no longer shoot well. Bore issues were the main culprit. That fine abrasive embeds into the lead projectile and scrapes all the way down the bore.

So how many rounds through the bore before accuracy declined?

I have said for years, I had a CZ452 I used in monthly competition (CMP Rimfire Sporter, Rimfire Silhouette), and at around 17000 rounds accuracy started deteriorating fast. Slugging revealed the bore’s tightest point was near the chamber and from there it opened up to the point I couldn’t believe a fired round wasn’t rattling down the bore.

I had purchased this rifle new, and used a weedwhacker patch pull cleaner after every match (chamber to muzzle).

It was about half way thru the season. About 8k rds. The CZ bore is tighter than most. There was wear at the throat and a big carbon ring that had not been cleaned out despite my regular cleaning. The leads looked like they had been hit with hammers. Most had metal protruding into the groves a tiny bit. Cleaned this all up and it is now shooting as good as ever. Once you get an inch down the bore, it looks ok. I would post tats from the last range session but they are out in the car.JG26_Irish,

So how many rounds through the bore before accuracy declined?

I have said for years, I had a CZ452 I used in monthly competition (CMP Rimfire Sporter, Rimfire Silhouette), and at around 17000 rounds accuracy started deteriorating fast. Slugging revealed the bore’s tightest point was near the chamber and from there it opened up to the point I couldn’t believe a fired round wasn’t rattling down the bore.

I had purchased this rifle new, and used a weedwhacker patch pull cleaner after every match (chamber to muzzle).

If y'er interested in barrel wear, contact the folks who have to deal with it as part of the factory testing.

Thousands of rounds a week sent through a barrel during batch grading.

Ask Eley, RWS, and Lapua how many rounds are tested before the test barrels are replaced.

I had heard quarter million but the answer is substantially less.

Customer service from each company asked the factory for the answer.

The replacement numbers were as low as 60k up to 180k depending on steel hardness.

Thousands of rounds a week sent through a barrel during batch grading.

Ask Eley, RWS, and Lapua how many rounds are tested before the test barrels are replaced.

I had heard quarter million but the answer is substantially less.

Customer service from each company asked the factory for the answer.

The replacement numbers were as low as 60k up to 180k depending on steel hardness.

Last edited:

I’ve heard the “crushed glass” statement for decades, mentioned it to a friend, here was his response:The particle that acts as an abrasive is silica.

Basically crushed glass that generates the spark that ignites the primer when impacted.

Part of the primer mix found in all rimfire cartridges.

It causes that fine linear scratch pattern seen in the rifling.

Silica is harder than steel and is blown into the bore with every shot fired.

Each succeeding shot pushes the silica along the rifling and acts as a polishing agent.

I can see in a series of images taken at 100 shot intervals that the new barrel tool marks

are being worn smooth. Good thing my OCD is willing to play with these long term projects.

I only know that I could find ZERO references to the use of silica in priming compound formulas.

I know that looking at the crystals I can find under my microscope they are foliated (repeated)and trapezoidal so have perfect cleavage.

This negates any possibility of the crystals I see as being quartz.

The person commenting is apparently assuming ALL silicate minerals are a 7 on the Mhos scale. There are MANY silicate minerals and the majority are all softer than steel. I do not give a single fuck what someone else misunderstands but you can’t cut a hard something with a soft something. If you are cutting something then there must be a contamination that is harder than the material being cut or there is a significant difference in tenacity. This different tenacity can be misleading. If a hard yet mailable surface is acted upon by a softer but higher tenacity and less mailable surface then it can leave scratching. It doesn’t actually remove material but rather mash it out of the way. Enough of that can eventually cause the surface of the more mailable to stuff of through cracking because of overwork. Cutting would be when the harder material actually removed material through direct action.

They silicate group is quite extensive and are often strongly piezoelectric. My guess is there may be an additive in primer compounds that manufactures use to help initiate ignition over the already sensitive material. It could also be used as a filler to lessen the need for the more expensive and volatile primer compounds. Either way If they do then the individual manufacturers keep it a protected secret because I spent quite a bit of time trying to identify the crystals I found. I could find no specific reference to them. I CERTAINLY DID NOT FIND ANY REFERENCES TO CRUSHED GLASS. Only the basic compound formulas. Lead styphanate, lead (2) azide, silver azide and potassium perchlorate are among the most widely used compounds components.

It may be the potassium perchlorate is forming the crystals during decomposition I have found and what people see that the assume through guessing that is glass.

_____________________________

Me: Do you mind if I post this?

_____________________________

Don’t care.

People will not understand it or try to pick it apart with bullshit opinion.

If they are silicates the problem is it’s the biggest mineral group on the planet. People see that word and look it up the first thing they see is quartz at a 7 on the scale. Yes a hardened steel file is only 6.5 so quartz will destroy it. Gun steel is actually quite soft steel. Not nearly as hard as people think. The problem is most silicate minerals are significant softer. They don’t read that far.

As far as the crystals I can see under my microscope (not unburned powder granules) absolutely have perfect cleavage planes. That rules out glass in any form as well as that first hit….quartz. Neither posses perfect cleavage.

I can crush those crystals under a piece of copper wire. Quite easily. If I isolate them and rub them on a hammer face under microscopic observation, they do leave marks. No metal was removed but it was absolutely left with a deformed surface. Not cut.

Unfortunately enough of that action overworks that surface layer and eventually the surface breaks free from inter crystalline cracking. Basically this, the steel gets worked quite extensively as individual crystals in the lattice but only a few microns deep. The steel underneath doesn’t get worked at all. Basically producing the same effect as bending a piece back and forth until it breaks. The steel isn’t affected anywhere except when it was getting bent. At a microscopic level it looks like abrasive action to the naked eye.

Your friend is weak with the Google fu.

A quick search brings up pages of references,

including Eley's problems with extreme bore erosion due to too much silica.

www.bevfitchett.us

www.bevfitchett.us

A patent search turns up multiple primer applications from companies

including the chemical composition. Silica is up to 20% of the total content.

Also, try this...

Disassemble a few rimfire cartridges.

Separate into component piles

Bullets

Powder

Primer

Brass

Rub the brass on a flat piece of steel

Check for scratches

Rub the bullet on a flat piece of steel

Check for scratches

Burn the pile of powder on a glass surface

Use the bullet to rub the burn residue on a flat steel plate

Check for scratches

Burn the pile of primer on a glass surface

Use a bullet to rub primer residue on a steel plate.

Check for scratches.

Guess which material I found causes scratches?

A quick search brings up pages of references,

including Eley's problems with extreme bore erosion due to too much silica.

Priming Compositions - Chemical Analysis Of Firearms

Priming compositions for firearms ammunition are mixtures which, when subjected to percussion, provide a sudden burst of flame that serves to ignite the

www.bevfitchett.us

www.bevfitchett.us

A patent search turns up multiple primer applications from companies

including the chemical composition. Silica is up to 20% of the total content.

Also, try this...

Disassemble a few rimfire cartridges.

Separate into component piles

Bullets

Powder

Primer

Brass

Rub the brass on a flat piece of steel

Check for scratches

Rub the bullet on a flat piece of steel

Check for scratches

Burn the pile of powder on a glass surface

Use the bullet to rub the burn residue on a flat steel plate

Check for scratches

Burn the pile of primer on a glass surface

Use a bullet to rub primer residue on a steel plate.

Check for scratches.

Guess which material I found causes scratches?

Last edited:

Similar threads

- Replies

- 13

- Views

- 875