I’m working on putting this yugo 48 Mauser into a new “semi inlet” walnut stock I got on eBay. I’ve never done any stock work and my only reference was the factory mil stock.

Working on getting the action and bottom metal fit into the inlet without any tension on the middle of the bottom metal. I made a pillar for the rear screw. Thinking about building something for the front screw once I get the correct distance between action and BM.

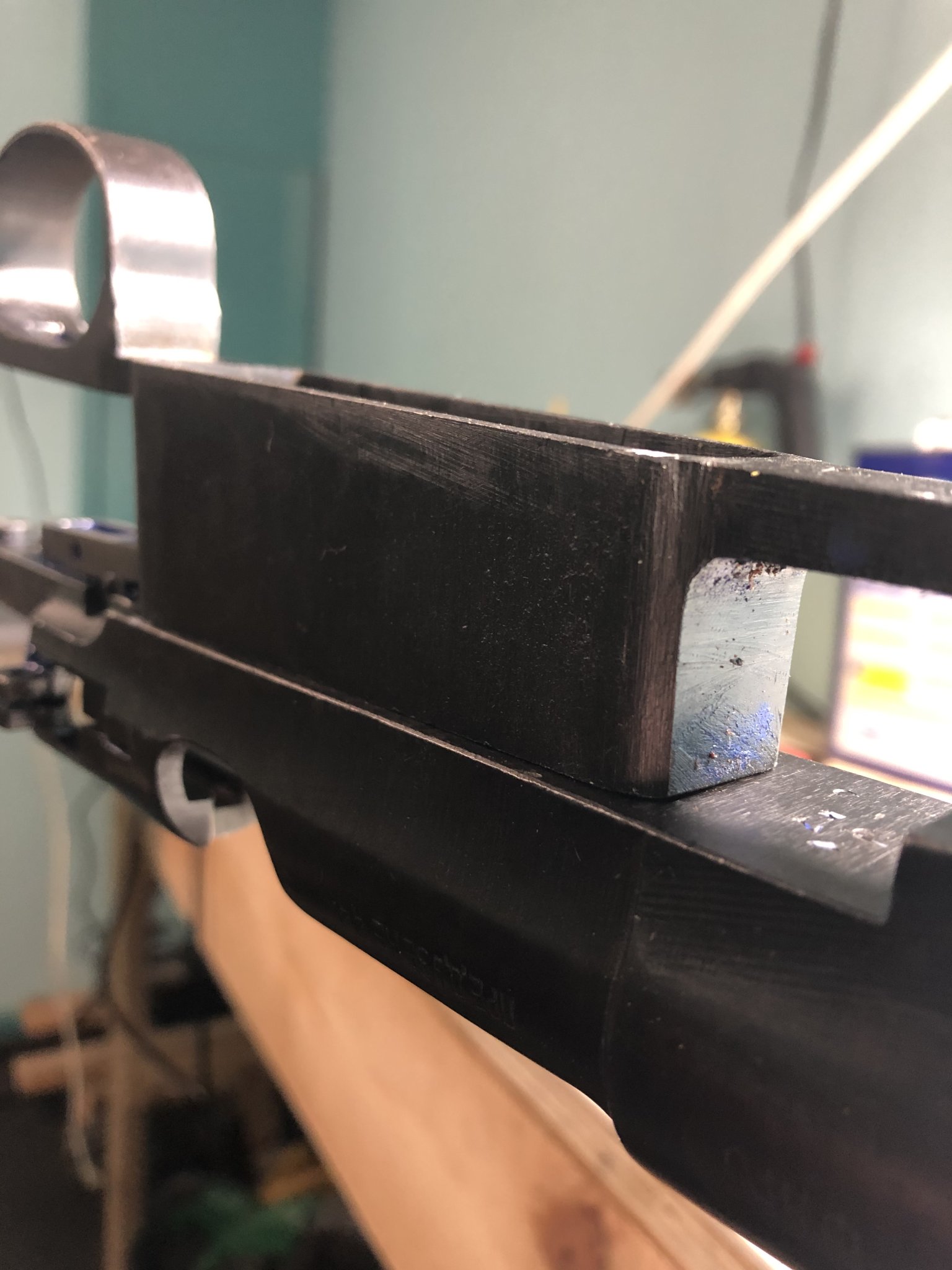

How critical is the top of the mag box touching the bottom of the action like the first pic. What about a little gap like the second?

Working on getting the action and bottom metal fit into the inlet without any tension on the middle of the bottom metal. I made a pillar for the rear screw. Thinking about building something for the front screw once I get the correct distance between action and BM.

How critical is the top of the mag box touching the bottom of the action like the first pic. What about a little gap like the second?