To save money. Anyone have any tricks to add weight to a cheap factory rifle stock. Such as adding foam or some kind of putty.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mods to factory stocks

- Thread starter BigPineyTradingPost

- Start date

most stocks have ways to open the back and taking action out there's likely a way to put some in the foreend even if you have to dremelGood one.

you could make some formed lead ingots too if you had the means

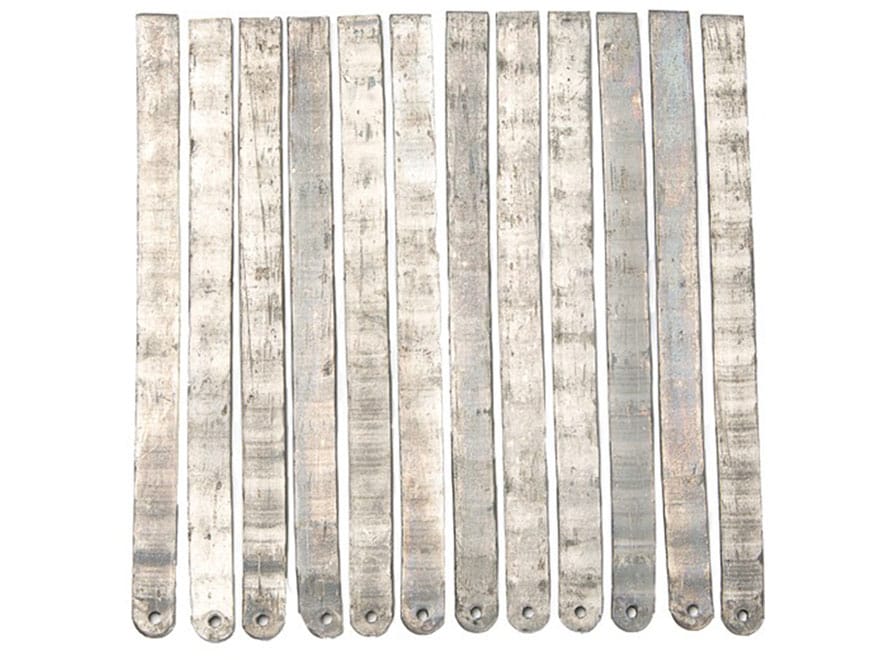

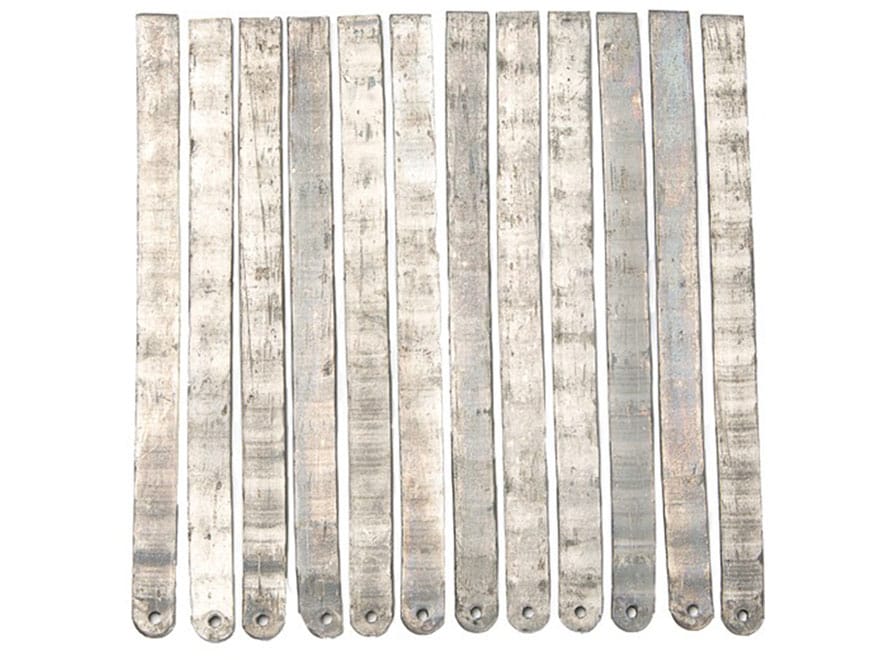

I used lead decoy weights and packed them in with Devcon to add 2lbs to a KRG Bravo. Can’t see it, but you can feel it.

ads.midwayusa.com

ads.midwayusa.com

Rig'Em Right Strap Decoy Weight 4oz Lead Pack of 12

Rig'Em Right Strap Weights stay where they're dropped. For storage, simply wrap the line around the keel and secure the flexible Strap Weight to the...

I would think lead bird shot would be the most efficient and easiest to get exactly the weight you wanted and were you wanted it.

Add the shot to the voids or channels in the stock and then seal it in with epoxy or whatever you prefer depending on the material.

Add the shot to the voids or channels in the stock and then seal it in with epoxy or whatever you prefer depending on the material.

Perfect!!!!!I would think lead bird shot would be the most efficient and easiest to get exactly the weight you wanted and were you wanted it.

Add the shot to the voids or channels in the stock and then seal it in with epoxy or whatever you prefer depending on the material.

I did the lead shot thing but just tied the shot into cut off fingers of Nitrile gloves, easy to remove or add weight.

But I also found that the real cheap stock I did it to (a Thompson factory stock) had way too much flex to truly benefit from additional weight. While firing, the stock was flexing at the action (ie the foregrip tended to stay in place for a moment due to the flex) A much stiffer cheap Boyd's stock did more for my cheap rifle than weight....

If your stock is already stiff, go for the weight....

But I also found that the real cheap stock I did it to (a Thompson factory stock) had way too much flex to truly benefit from additional weight. While firing, the stock was flexing at the action (ie the foregrip tended to stay in place for a moment due to the flex) A much stiffer cheap Boyd's stock did more for my cheap rifle than weight....

If your stock is already stiff, go for the weight....

I did the lead shot thing but just tied the shot into cut off fingers of Nitrile gloves, easy to remove or add weight.

But I also found that the real cheap stock I did it to (a Thompson factory stock) had way too much flex to truly benefit from additional weight. While firing, the stock was flexing at the action (ie the foregrip tended to stay in place for a moment due to the flex) A much stiffer cheap Boyd's stock did more for my cheap rifle than weight....

If your stock is already stiff, go for the weight....

An old mod for flexible USGI fiberglass M14 stocks is to epoxy carbon fiber arrow shafts on the sides. It's impressively effective. I've also built up fiberglass layers as well, but that takes a little more effort. Could probably work for a factory stock. Another idea to stiffen it would be to use a full length arca rail.

I have plenty of old Carbon arrows.An old mod for flexible USGI fiberglass M14 stocks is to epoxy carbon fiber arrow shafts on the sides. It's impressively effective. I've also built up fiberglass layers as well, but that takes a little more effort. Could probably work for a factory stock. Another idea to stiffen it would be to use a full length arca rail.

I have plenty of old Carbon arrows.

Problem is gluing anything to plastic... most cheap rifle stocks are plastic not fiberglass. About the only adhesive I found that will stay attached to plastic stocks is Plexus. Super expensive and not readily available as far as I know.

we recently had a series of posts on just this topic...i have used Duct Seal very successfully to fill the void in buttstock, i wrap the Duct Seal in Saran Wrap so that i can easily remove it should i chose to. It's very heavy/dense...and cheap.

Here's the series of posts: https://www.snipershide.com/shootin...for-multi-purpose-stock.6964243/#post-8001019

Here's the series of posts: https://www.snipershide.com/shootin...for-multi-purpose-stock.6964243/#post-8001019

Problem is gluing anything to plastic... most cheap rifle stocks are plastic not fiberglass. About the only adhesive I found that will stay attached to plastic stocks is Plexus. Super expensive and not readily available as far as I know.

I used 100 grit sand paper to scuff the inside of a factory Tikka stock and JB welded my Picatinny rail's anchor nut in. Seemed to work. No idea on long term durability though.

Problem is gluing anything to plastic... most cheap rifle stocks are plastic not fiberglass. About the only adhesive I found that will stay attached to plastic stocks is Plexus. Super expensive and not readily available as far as I know.

I've glued lots of stuff to plastic. Clean, scuff, clean, clean again, pour epoxy. Devcon and acuglass also work for bedding, no reason they couldn't secure some carbon into routered channels.

And it keeps surprising me, but JB Weld will stick to damn near everything so long as you're not putting it in tension it holds up admirably.

I've used plastic balloons which I placed in the cavity to be filled and then filled them up with annealed steel shot, tied off the balloon and stuffed some empty balloons around it to make sure the weight did not shift. Now I'm using KRG's forend weight, and the heavy LOP spacers. Epoxy is permanent and I like to keep my options open in case I want to replace the barreled action.I would think lead bird shot would be the most efficient and easiest to get exactly the weight you wanted and were you wanted it.

Add the shot to the voids or channels in the stock and then seal it in with epoxy or whatever you prefer depending on the material.

I've used plastic balloons which I placed in the cavity to be filled and then filled them up with annealed steel shot, tied off the balloon and stuffed some empty balloons around it to make sure the weight did not shift. Now I'm using KRG's forend weight, and the heavy LOP spacers. Epoxy is permanent and I like to keep my options open in case I want to replace the barreled action.

That's another good option, many ways to skin that cat ?

Since the original question was regarding the flimsy Tupperware stocks I personally wouldn't have any reservations about making it permanent since the next realistic step is an upgrade.