A few moments where I depreciate the value of my neighborhood. Living amongst senior citizens has its advantages during times like this, as most are deaf as a post.

The data log reveals some interesting stuff. Idle lands around 1050rpm once it warms up. A 0-100% throttle whack sends the RPM to over 3,800 in 400ths of a second. The impressive (or scary) part is that during the blip, the atmosphere inside the engine changes from 14" of vacuum to +11psi worth of boost. This one has some big lungs, lol.

Still lots to do, but it at least starts and moves now.

The dry sump oil pump belt alignment has a small tracking error that I'm still working on. I have a .025" shim on the pump mount now that seems to help. I might have to add a little more.

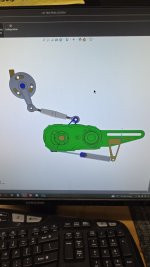

The next big problem to solve is power management. This is a small tire car, and I estimate the engine to land somewhere around 2k for power output. Putting all of that to a 10" wide radial tire is asking a lot. I am not a fan of 2-step rev limiting strategies on blower motors as it's hell on parts. The mass of a pair of rotors whirling around as they are rapidly +/- in rpm as the computer pulls/adds cylinders (ignition) is not a good thing. A friend who's much smarter than I am has a pretty clever alternative solution using a stock GM throttle-by-wire throttle body. I ordered a pair and am dissecting them now for the upcoming experimental transplant surgery.

If it works, the engine will no longer crackle and pop. It'll just increase rpm, hold, and accelerate off the line with smooth/linear progression. Add some peripherals (traction control), and we might have a good solution for how to launch/control this dumb thing.

The data log reveals some interesting stuff. Idle lands around 1050rpm once it warms up. A 0-100% throttle whack sends the RPM to over 3,800 in 400ths of a second. The impressive (or scary) part is that during the blip, the atmosphere inside the engine changes from 14" of vacuum to +11psi worth of boost. This one has some big lungs, lol.

Still lots to do, but it at least starts and moves now.

The dry sump oil pump belt alignment has a small tracking error that I'm still working on. I have a .025" shim on the pump mount now that seems to help. I might have to add a little more.

The next big problem to solve is power management. This is a small tire car, and I estimate the engine to land somewhere around 2k for power output. Putting all of that to a 10" wide radial tire is asking a lot. I am not a fan of 2-step rev limiting strategies on blower motors as it's hell on parts. The mass of a pair of rotors whirling around as they are rapidly +/- in rpm as the computer pulls/adds cylinders (ignition) is not a good thing. A friend who's much smarter than I am has a pretty clever alternative solution using a stock GM throttle-by-wire throttle body. I ordered a pair and am dissecting them now for the upcoming experimental transplant surgery.

If it works, the engine will no longer crackle and pop. It'll just increase rpm, hold, and accelerate off the line with smooth/linear progression. Add some peripherals (traction control), and we might have a good solution for how to launch/control this dumb thing.

Last edited: