i saw a discussion here the other day about bolt truing and hating to use the steady rest. i came up with a simple solution that allows all operations to be done in one setup, and no steady rest. it was so obvious, once i thought of it, it was one of those "why didn't i think of that before" moments.

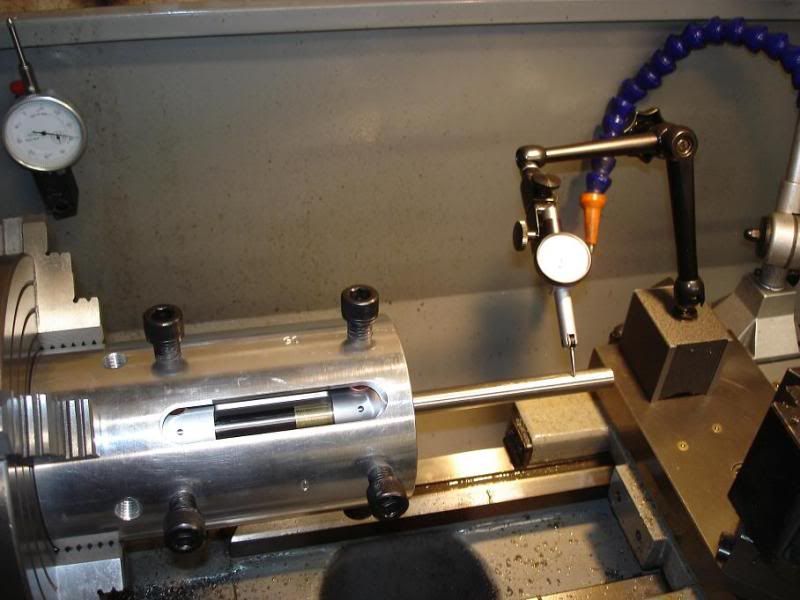

i already had my action truing jig that i made a while back. a bolt wouldn't fit in it because of the handle. i machined a slot in the jig to allow the bolt handle to fit though. i thread my 1/2-13 mandrel that i had been using for bolt work into the rear of the bolt. this is where the rear adjusting screws ride on. the front adjusting screws are against the bolt body. i give it enough stickout to be able to indicate in a couple spots and have enough room to get a tool on the rear of the lugs.

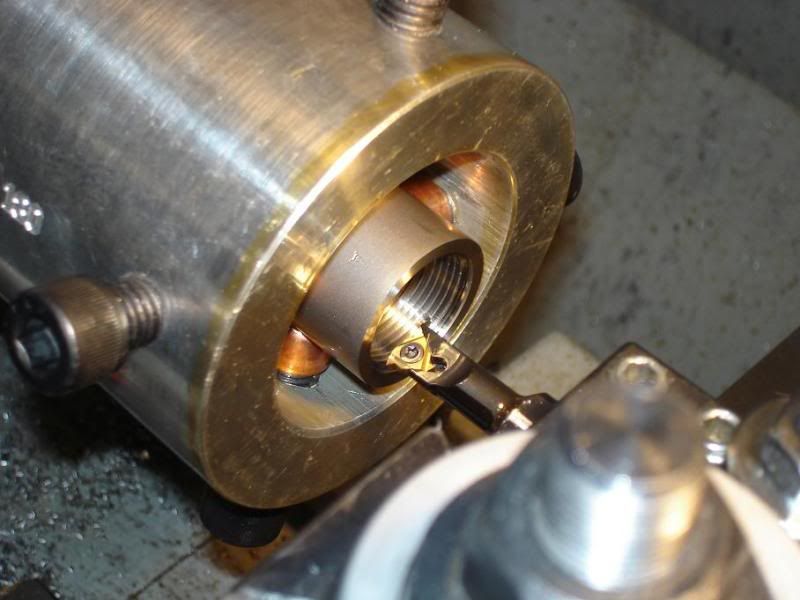

this is not a set up for heavy machining or high rpm but it worked great for this purpose. once the bolt was done i could go straight to truing the receiver in the same jig.

i already had my action truing jig that i made a while back. a bolt wouldn't fit in it because of the handle. i machined a slot in the jig to allow the bolt handle to fit though. i thread my 1/2-13 mandrel that i had been using for bolt work into the rear of the bolt. this is where the rear adjusting screws ride on. the front adjusting screws are against the bolt body. i give it enough stickout to be able to indicate in a couple spots and have enough room to get a tool on the rear of the lugs.

this is not a set up for heavy machining or high rpm but it worked great for this purpose. once the bolt was done i could go straight to truing the receiver in the same jig.