Like a lot of reloaders, I have several digital calipers ranging in price from $20 to $100 and was using them at will for just about anything reloading. But then I noticed some were more accurate or inaccurate than others -- particularly giving me different readings on headspaces when using a Hornady L-N-L setup.

Do any of you know of a common household object, such as a nickel or a quarter coin, that has a precise width or thickness that I can check all of these digitals against.

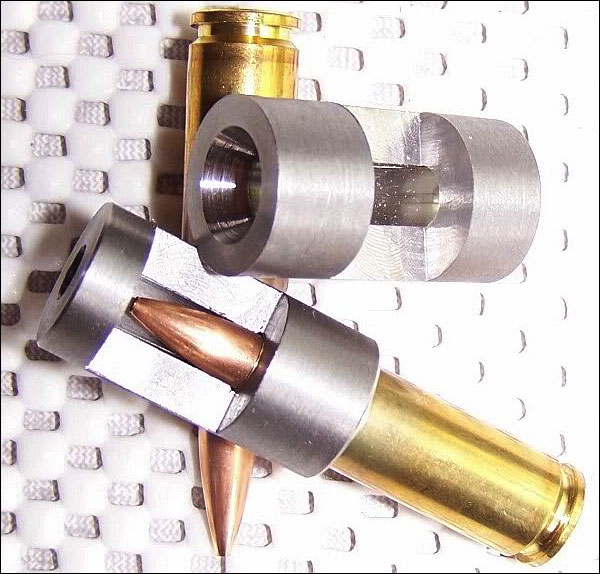

BTW, I try mimicking new, virgin Lapua brass measurements when setting up my sizing dies in .223 and .308. That is when I swapped out a digital caliper and got a widely different reading on the new Lapua. And it's not the brass.

Do any of you know of a common household object, such as a nickel or a quarter coin, that has a precise width or thickness that I can check all of these digitals against.

BTW, I try mimicking new, virgin Lapua brass measurements when setting up my sizing dies in .223 and .308. That is when I swapped out a digital caliper and got a widely different reading on the new Lapua. And it's not the brass.