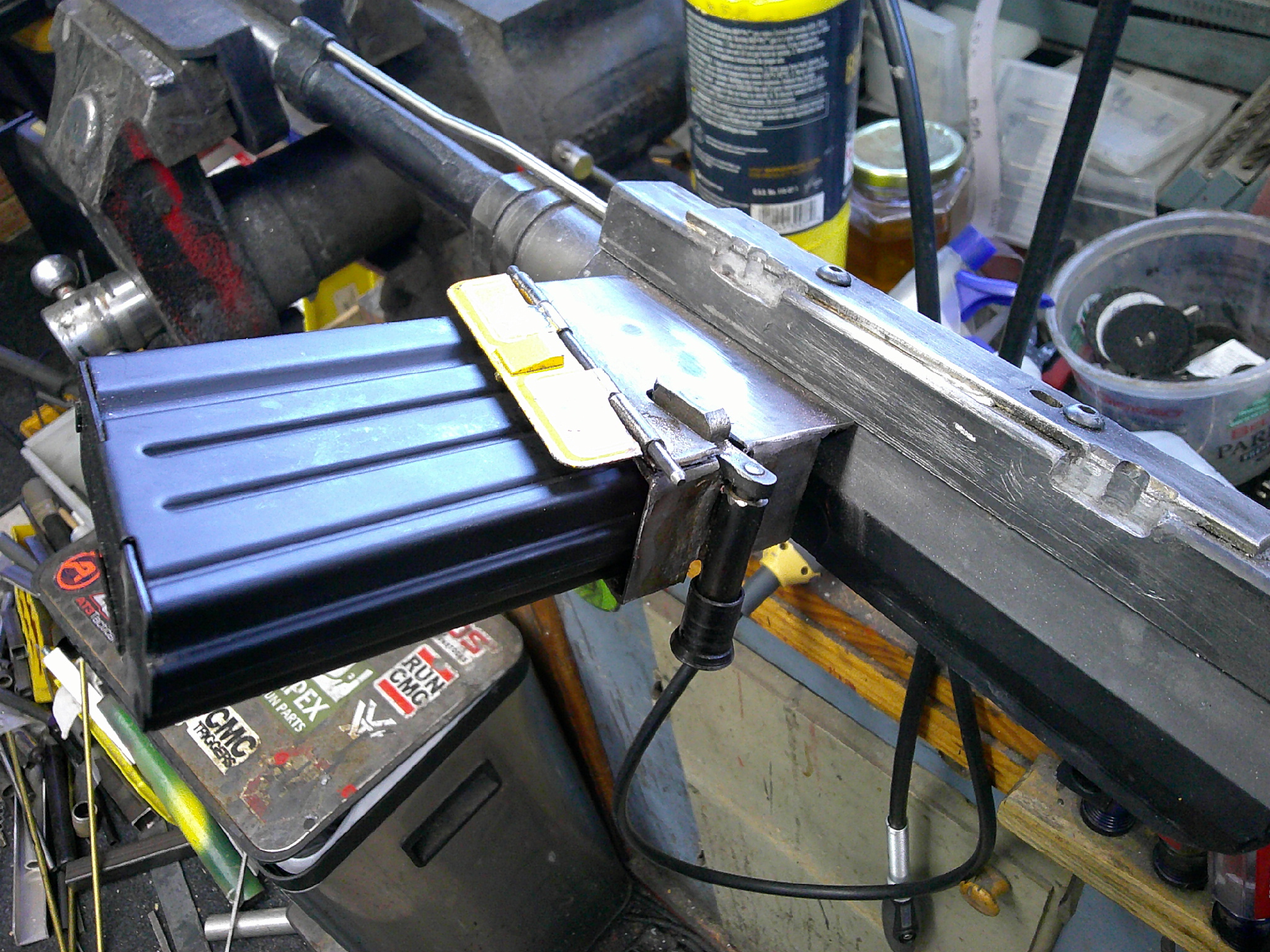

I just made this part for my new project. Can you identify what weapon? Being the Hide, I'm pretty sure your first guess will be wrong....it neither vibrates nor does it need batteries. Here's a clue: it's a muzzle brake; but, to what firearm?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Project: Fallshirmjaeger Gewehr 42 NEW: Test Fire Video

- Thread starter buffalowinter

- Start date

Tho

Edit: forgot the question mark. Because I definitely do not know what I am talking about.

Thompson .45I just made this part for my new project. Can you identify what weapon? Being the Hide, I'm pretty sure your first guess will be wrong....it neither vibrates nor does it need batteries. Here's a clue: it's a muzzle brake; but, to what firearm?View attachment 8353032

Edit: forgot the question mark. Because I definitely do not know what I am talking about.

Dickfer?

Fallschirmjägergewehr 42

Dickfer: QED quod erat demonstrandum

Correct, FG 42

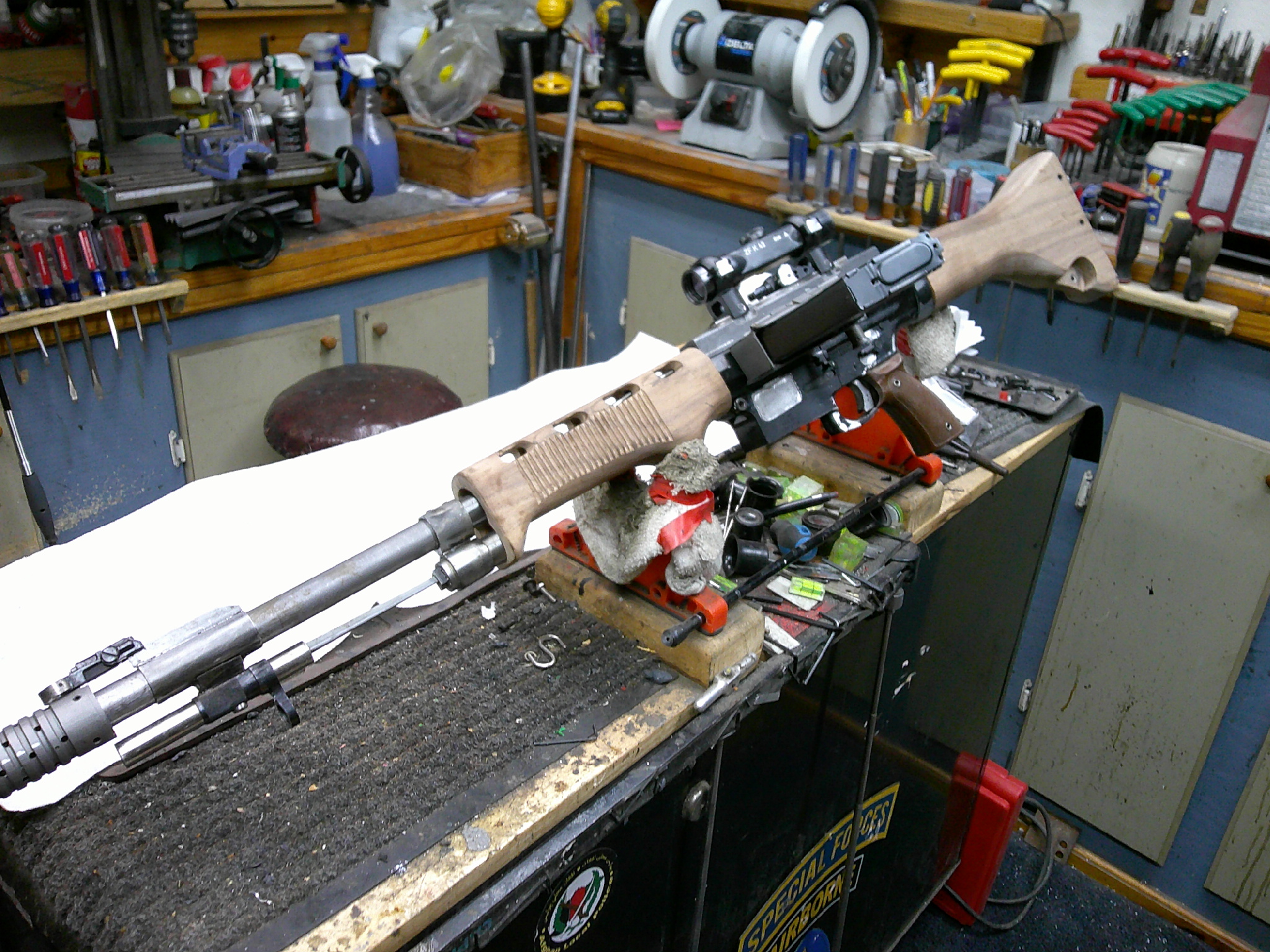

I'm building a sort of product improved FG 42 based on a VisMod AR-10

Little late for Valentine's Day there, good buddy.

Gathering parts. The more I look into it, the better I like this project. I'm going to base this on a side charging AR 10 in .308.

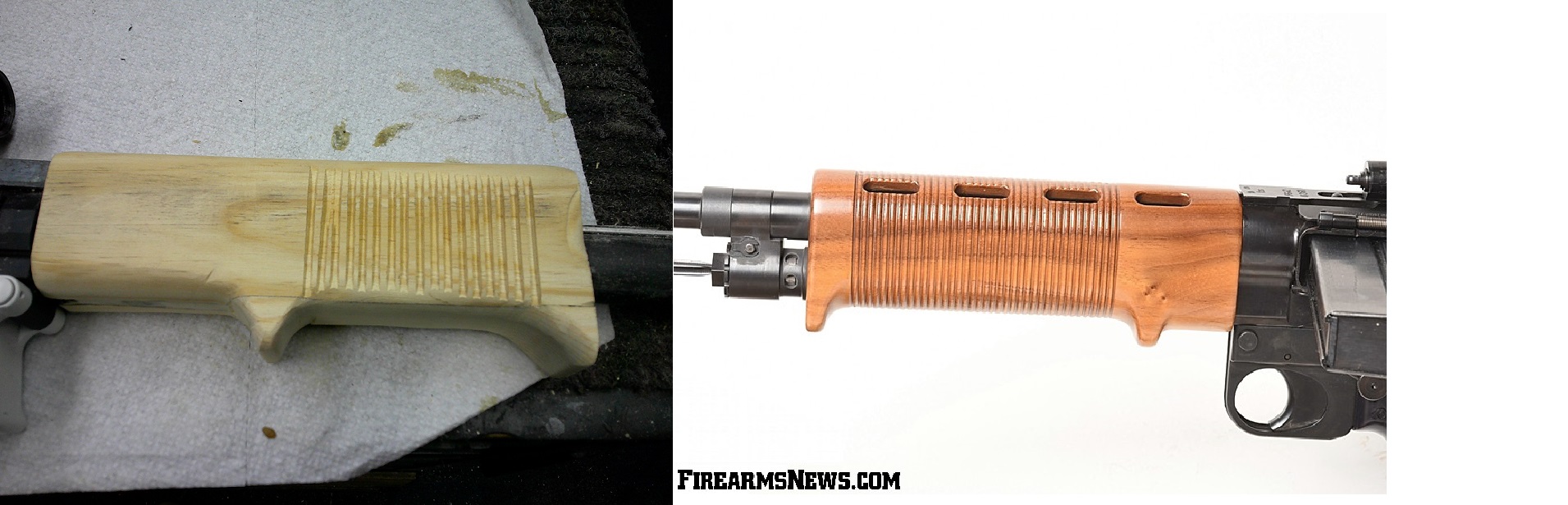

Was trying to sort out what grips to use that would closely match the originals. Who knew? There are a lot of repro FG 42 grips for sale. These are from NC Ordnance.

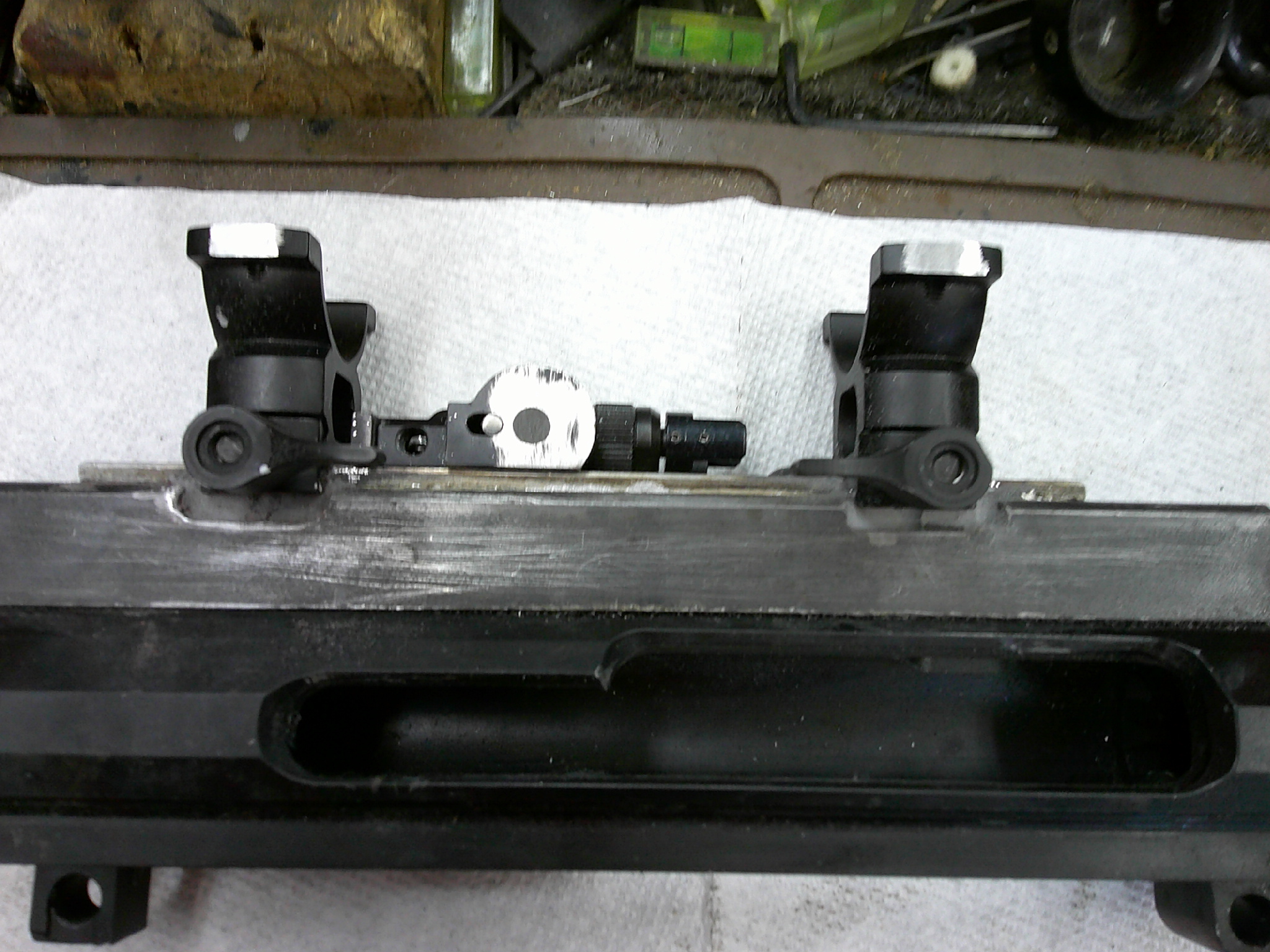

This will be the rear sight, after modifications.

I'll modify this Griffin Armament front sight

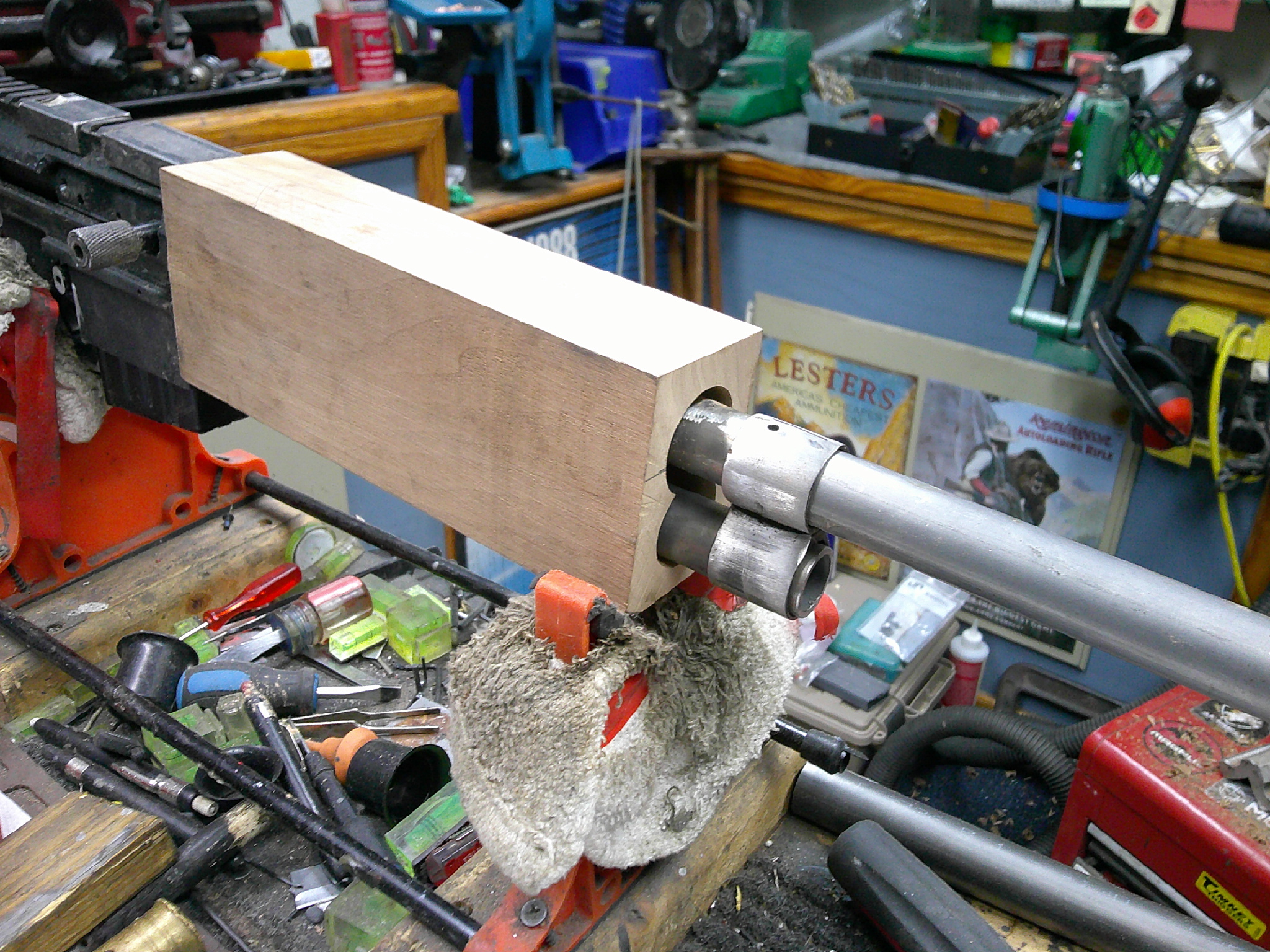

Making a pine prototype of the butt stock. Once all the dimensions are worked out, the final butt stock will be made from beech.

Enlarged the ports on the brake and did an initial Cerakote. There are some spanner cuts on the muzzle of the brake that have to be done once it is installed.

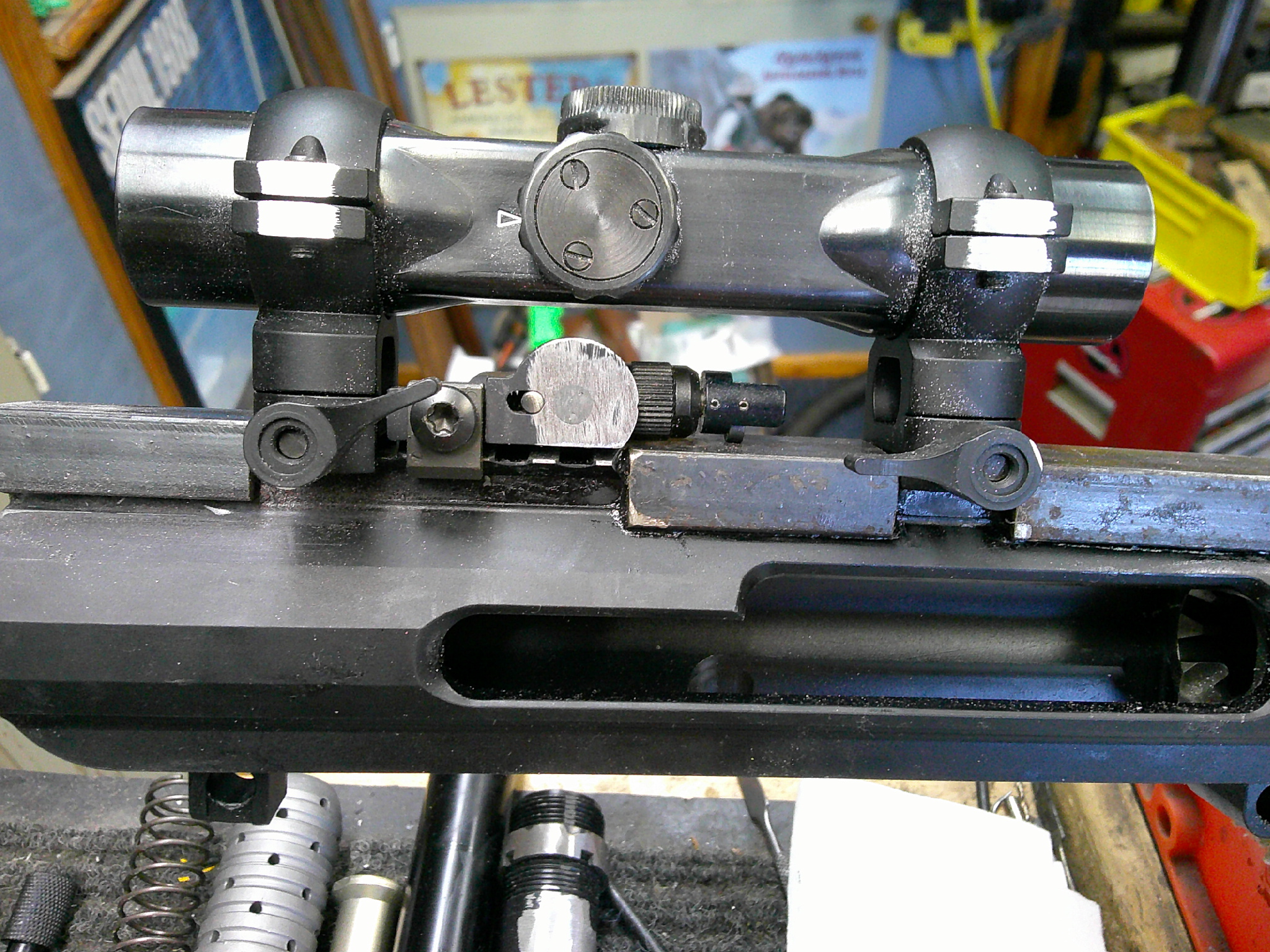

I'll being modifying a repro ZF 4 scope with quick release mounts

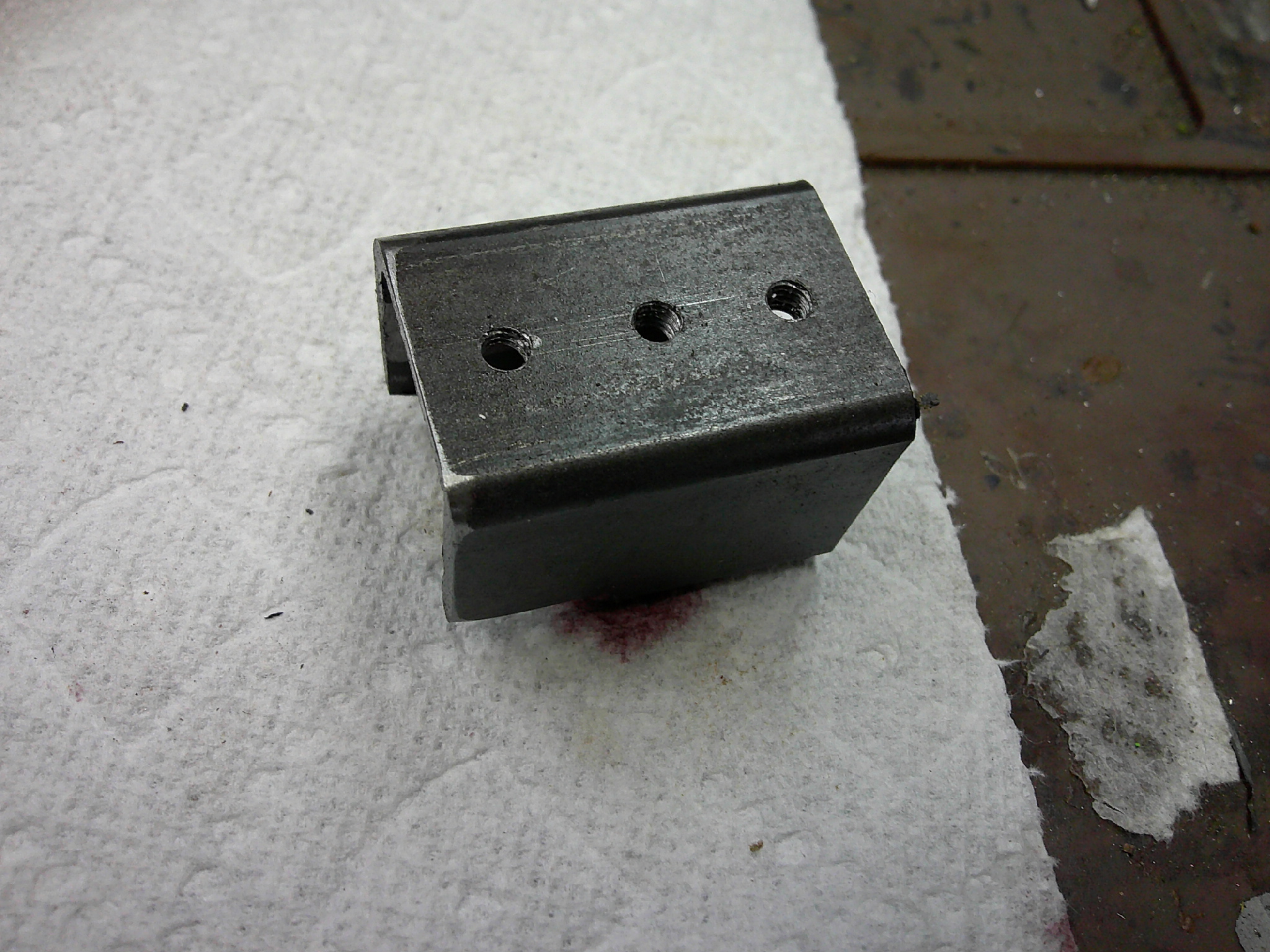

I'll be re-creating the "look" of the side loading magazine by manufacturing a "magazine holder" type redi-mag that will be non-functional, except that it can carry a loaded mag.

Was trying to sort out what grips to use that would closely match the originals. Who knew? There are a lot of repro FG 42 grips for sale. These are from NC Ordnance.

This will be the rear sight, after modifications.

I'll modify this Griffin Armament front sight

Making a pine prototype of the butt stock. Once all the dimensions are worked out, the final butt stock will be made from beech.

Enlarged the ports on the brake and did an initial Cerakote. There are some spanner cuts on the muzzle of the brake that have to be done once it is installed.

I'll being modifying a repro ZF 4 scope with quick release mounts

I'll be re-creating the "look" of the side loading magazine by manufacturing a "magazine holder" type redi-mag that will be non-functional, except that it can carry a loaded mag.

Last edited:

Prototype stock finished. The stock is a couple inches longer than the original to accept a full length AR-10 buffer tube. I think for the final copy I'll make an exact replica and use a carbine tube. I'll test fire the upper with a carbine lower and a rifle lower and see what works best.

Last edited:

Scope and iron sights mounted on modified receiver.

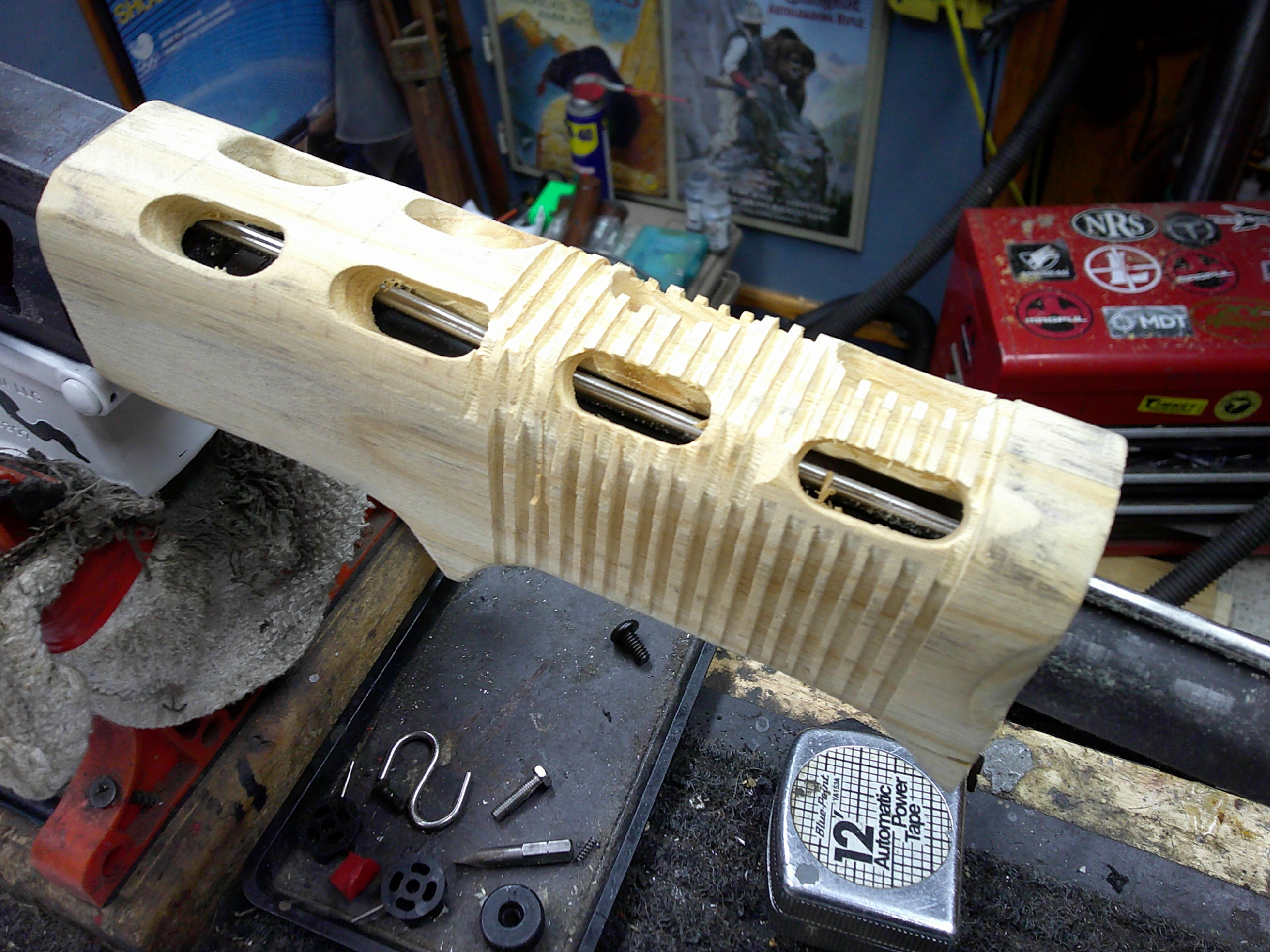

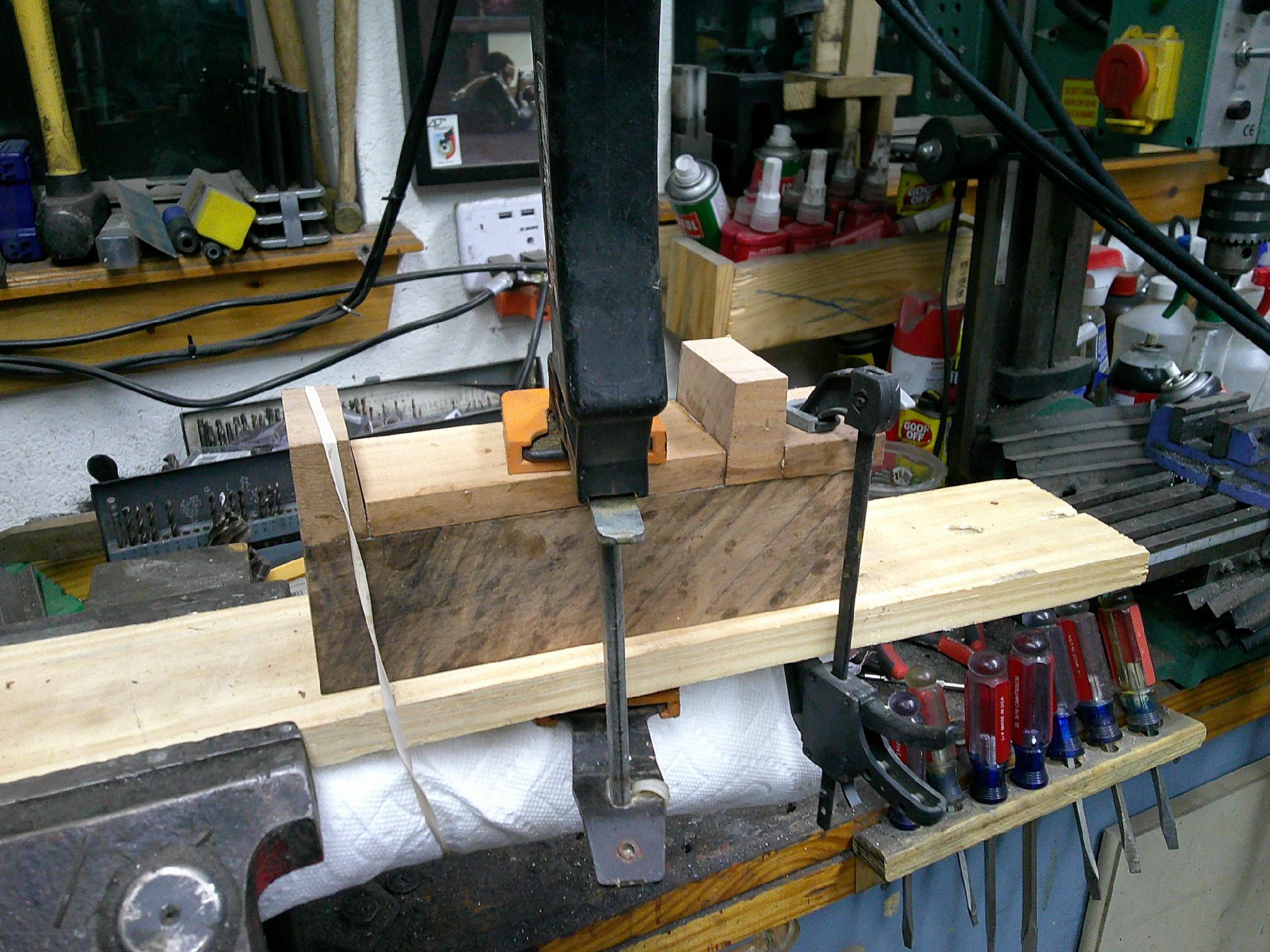

Making the prototype fore end from laminated pine...probably the most difficult part of the project. Already two lessons learned that saves me wasting expensive Birch and Beech blanks.

Coming together. Have to drill the vent holes and then make a dado joint for the little wings. The proportions will be correct on the final model.

Last edited:

Came out pretty well. The final will be longer and closer to proportion but still a little longer than the original to blend better with the mid-length gas tube. I could weld up the gas port and drill a carbine length gas port but I would run into the same problem the original German designers had with too much gas pressure. They solved it by having a stepped chamber where the cartridge would expand into these steps to relieve the pressure and slow blowback. I could probably fix it with an adjustable gas block, but at this point it's not worth it. Plus, the upper functions fine, that is why the snow camo lower is on the rifle. The final will have a lot sharper edges using hardwood rather than scrap pine.

I find your posts absolutely fascinating sir- looking forward to see how it ends up.Came out pretty well. The final will be longer and closer to proportion but still a little longer than the original to blend better with the mid-length gas tube. I could weld up the gas port and drill a carbine length gas port but I would run into the same problem the original German designers had with too much gas pressure. They solved it by having a stepped chamber where the cartridge would expand into these steps to relieve the pressure and slow blowback. I could probably fix it with an adjustable gas block, but at this point it's not worth it. Plus, the upper functions fine, that is why the snow camo lower is on the rifle. The final will have a lot sharper edges using hardwood rather than scrap pine.

View attachment 8358302

View attachment 8358303

View attachment 8358304

View attachment 8358305

View attachment 8358306

-LD

I did just find an ar-10 308 pistol barrel with a carbine length gas tube. I'm going to thread a barrel extension on and then pin and weld to 19.7 inches. That will make the gas system hidden under the handguard and the handguard an exact copy..I find your posts absolutely fascinating sir- looking forward to see how it ends up.

-LD

Apologize for prying but if you don't mind me asking- for the past few years that I've had an account here you continue to post amazing builds but your profile suggests an 18 series background and I'm just curious where your machining prowess comes from? Obviously no requirement to respond back but dang I've been so impressed with what you've been able to produce (and as a hobby I'd imagine which is ever more so impressive to me).I did just find an ar-10 308 pistol barrel with a carbine length gas tube. I'm going to thread a barrel extension on and then pin and weld to 19.7 inches. That will make the gas system hidden under the handguard and the handguard an exact copy..

-LD

Been tinkering/building guns for 50 years. Retired from the Army in the mid 90's and started competing in Cowboy Action Shooting. I was continually disappointed in the gunsmithing available to make my cowboy guns match grade and capable of winning a World Championship. So, I started working on my own guns, learning by doing. This resulted in 7 World Champion titles in different shooting sports. When the internet came around in the early 2000's the information available was a godsend. I upgraded my equipment with a mini-mill, mini-lathe, heavy duty drill press with machinist table, and a barn full of wood working and metal working tools. Welders, sanders, saws, grinders etc. I started with just doing file work. I'm still good at the lost art of doing old school file work and making stocks from blanks. A lot of it is art and design. I was a professional artist for about 10 years after I retired, specializing in Native American sculpture/3d collage art. Those creative skills transfer well to gun design and bringing ideas to reality.Apologize for prying but if you don't mind me asking- for the past few years that I've had an account here you continue to post amazing builds but your profile suggests an 18 series background and I'm just curious where your machining prowess comes from? Obviously no requirement to respond back but dang I've been so impressed with what you've been able to produce (and as a hobby I'd imagine which is ever more so impressive to me).

-LD

Native American Horse Stick sculptures.

I also made the picture frame in the background. Plus a lot of our furniture and cabinetry in our house...which I designed.

Thank you sir- your posts speak for themselves and I'm humbled that you took the time to respond back to me. I'll continue to look forward to what you're able to build and keep history alive. Stunning work by the way.Been tinkering/building guns for 50 years. Retired from the Army in the mid 90's and started competing in Cowboy Action Shooting. I was continually disappointed in the gunsmithing available to make my cowboy guns match grade and capable of winning a World Championship. So, I started working on my own guns, learning by doing. This resulted in 7 World Champion titles in different shooting sports. When the internet came around in the early 2000's the information available was a godsend. I upgraded my equipment with a mini-mill, mini-lathe, heavy duty drill press with machinist table, and a barn full of wood working and metal working tools. Welders, sanders, saws, grinders etc. I started with just doing file work. I'm still good at the lost art of doing old school file work and making stocks from blanks. A lot of it is art and design. I was a professional artist for about 10 years after I retired, specializing in Native American sculpture/3d collage art. Those creative skills transfer well to gun design and bringing ideas to reality.

Native American Horse Stick sculptures.

View attachment 8358396

I also made the picture frame in the background. Plus a lot of our furniture and cabinetry in our house...which I designed.

View attachment 8358397

-LD

That little factoid is quite incredible. I have said it before, and I'll say it again: You got skills(!).So, I started working on my own guns, learning by doing. This resulted in 7 World Champion titles in different shooting sports.

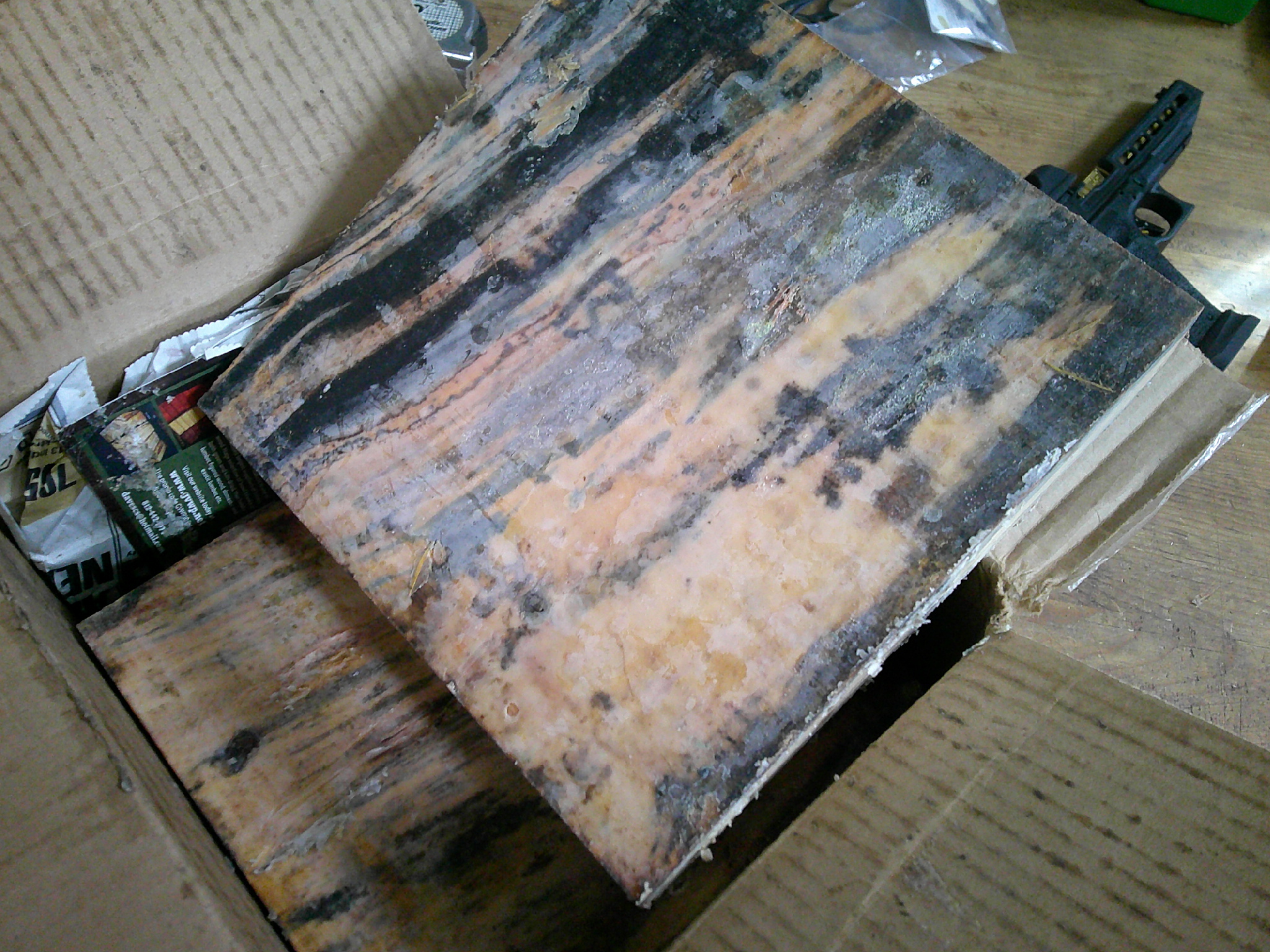

Got the birch blank, here's what it looks like, covered in protective wax.

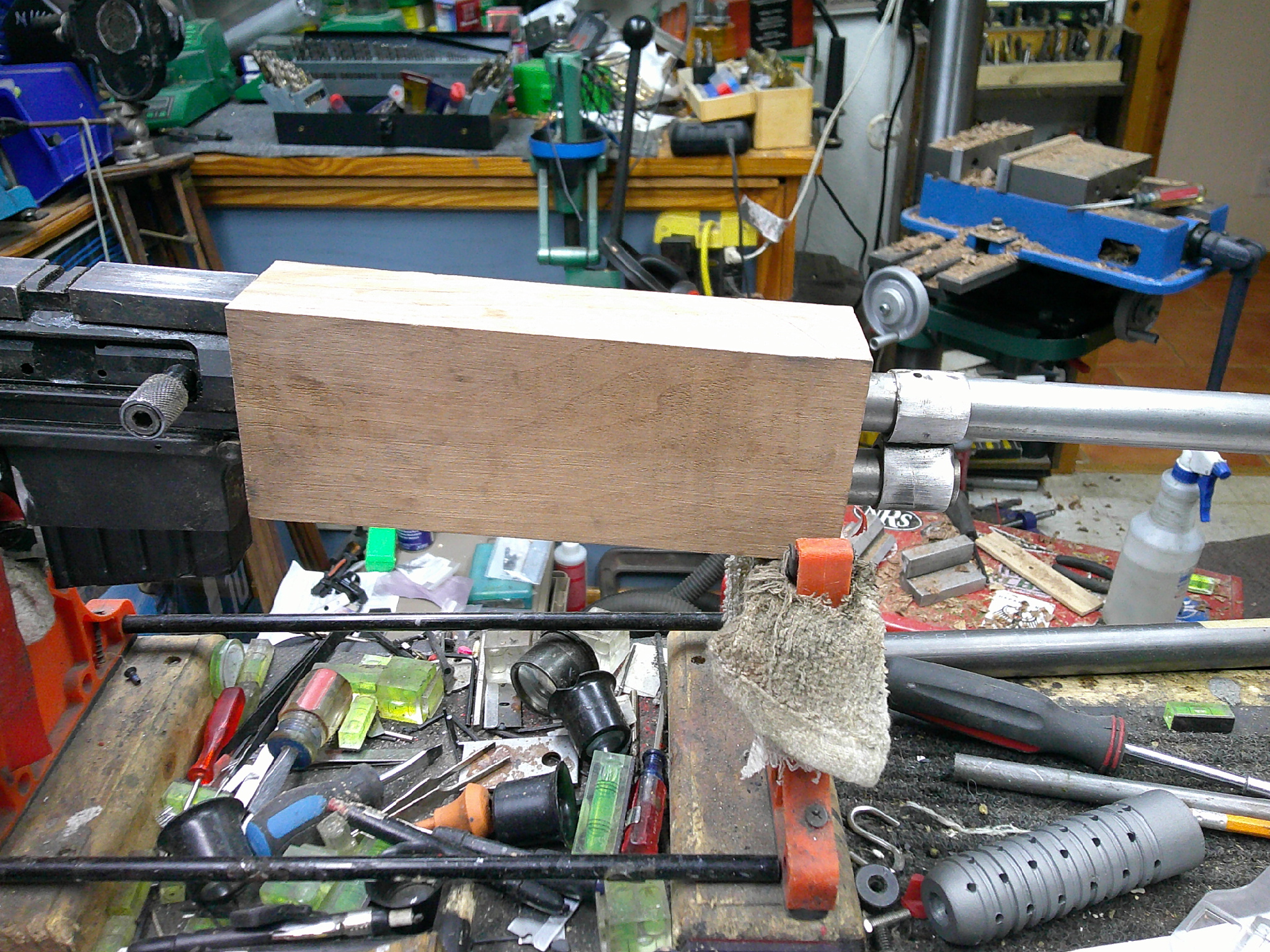

Cut down and sanded to stock gross dimensions.

Here's the forearm with the little side "wing" added. Came out pretty good. Overall length is good but needs to be a little wider. Have to move the bottom "wing" about an inch to the rear.

Have a little bit of cutting, welding and fabricating to make the MG 42 bipod semi-correct.

Cut down and sanded to stock gross dimensions.

Here's the forearm with the little side "wing" added. Came out pretty good. Overall length is good but needs to be a little wider. Have to move the bottom "wing" about an inch to the rear.

Have a little bit of cutting, welding and fabricating to make the MG 42 bipod semi-correct.

Last edited:

Started work on the stock using birch. Also started on the lower and pistol grip. I'm at the point where you have to do several things at once to get them all to line up.

Stock and lower

Lower. Had to modify the trigger guard, mag well, and tang for the grip.

Had to turn down a KAK buffer tube and drilled the thru hole for stock. Lots of mods to the stock ferrule, castle nut, and back plate.

No point in cleaning up, it's just going to be a mess tomorrow too.

Stock and lower

Lower. Had to modify the trigger guard, mag well, and tang for the grip.

Had to turn down a KAK buffer tube and drilled the thru hole for stock. Lots of mods to the stock ferrule, castle nut, and back plate.

No point in cleaning up, it's just going to be a mess tomorrow too.

Stock is ready for oil. Shaped, sanded, battle damage applied, and final sanded.

Almost forgot the details, Stock ferrules, sling cutout and ferrule, and takedown button.

Getting ready to bed and shape fore end . Going to use two threaded screws thru stock bushings to attach to the barrel nut.

The plan continues to evolve. The problem with AR type conversions is the gas tube really distracts from the illusion. I had originally planned to use a 19.7" barrel with a mid-length tube. I switched to a 12.7" carbine barrel with a carbine tube. The hand guard will completely hide the gas tube. I pinned and welded a barrel extension to get the original 19.7".

Handguard in walnut

Mock up

The good news is, I test fired the upper with the carbine barrel and the lower with a binary trigger and it worked flawlessly. The binary trigger really throws some rounds down range. The bad news is, the thing really has stout recoil. So much so, that after only 20 rounds, the Birch stock developed cracks. Now I'm making a new stock in Walnut from a stock blank, i.e. quarter sawn. I suspect the Birch stock cracked from being flat sawn, which is not as strong as quarter sawn. The strongest, and also very authentic for German arms, is a lamination, which I may do on the follow on FG 42.

New Walnut blank

Handguard in walnut

Mock up

The good news is, I test fired the upper with the carbine barrel and the lower with a binary trigger and it worked flawlessly. The binary trigger really throws some rounds down range. The bad news is, the thing really has stout recoil. So much so, that after only 20 rounds, the Birch stock developed cracks. Now I'm making a new stock in Walnut from a stock blank, i.e. quarter sawn. I suspect the Birch stock cracked from being flat sawn, which is not as strong as quarter sawn. The strongest, and also very authentic for German arms, is a lamination, which I may do on the follow on FG 42.

New Walnut blank

Made a new stock in Walnut. Much better.

Working on the handguard. Fitted to receiver and work on gas block started.

Well, it's a 12.7" barrel, I figure it can only get better.Will the pin and welded extension cause any issues with accuracy?

Working on front sight. A pretty complicated piece. It includes an integral bayonet mount and sling mount. The bipod mounts between the sight mount and the muzzle brake. The bayonet pulls forward out of its mount and then locks back into it.

Re-did the scope and iron sight mount

Re-did the scope and iron sight mount

Working on the magazine well which serves as a "Redi-Mag". The gun loads thru the normal AR-10 mag well.

Waiting on bipod parts. test fire #2 tomorrow, then metal prep, Cerakote, and wood finish.

Down to details and building bipod. Then bead blast, prep for Cerakote Glacier Black and finish.

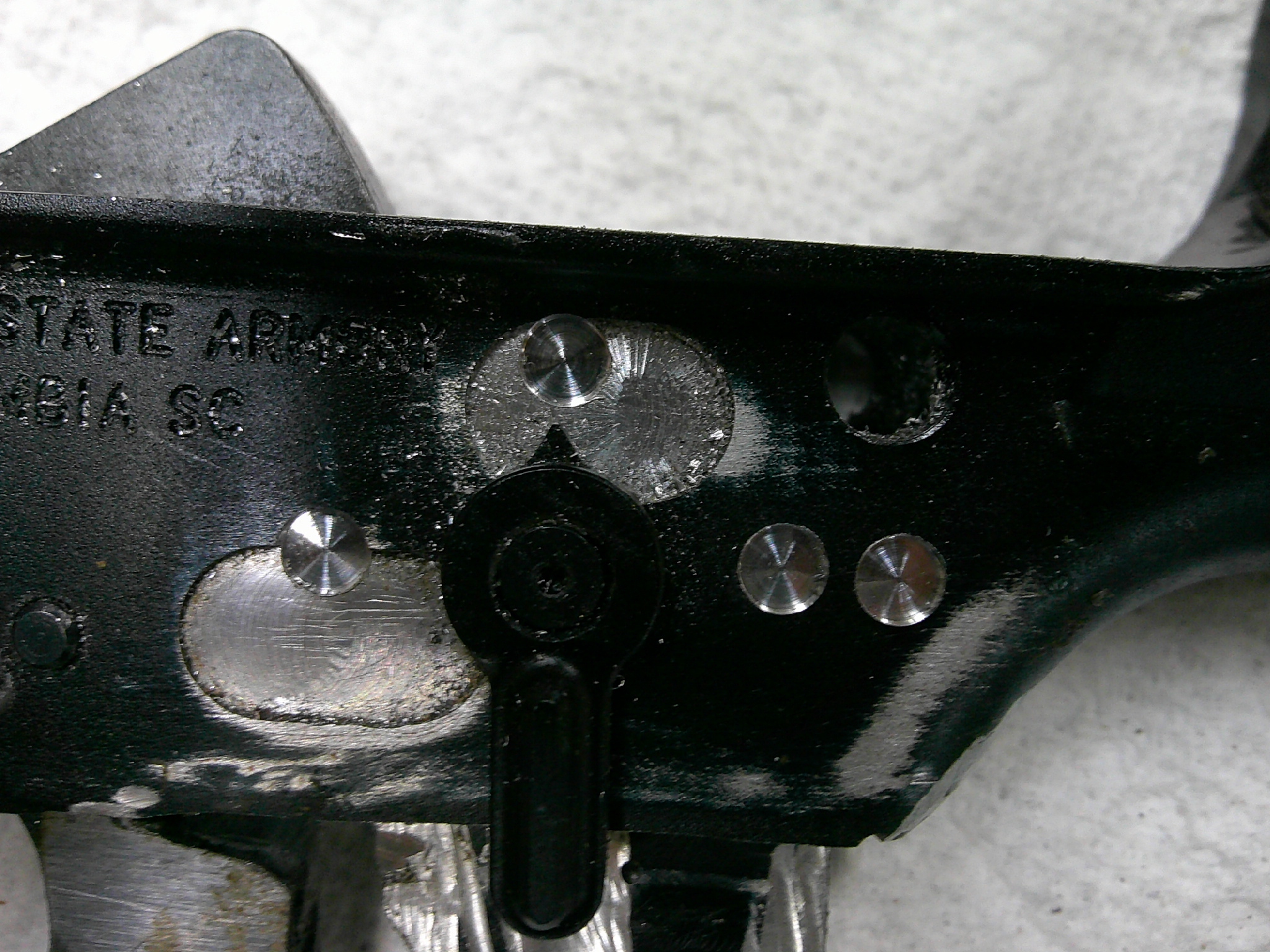

Receiver markings

Markings for fire controls. green dot for safe, red dot for semi, two red dots for binary.

Bipod bridge

Fronsight, sling, bayonet assembly.

Solid trigger

Walnut butt stock and fore end finished in Danish Red Mahogany oil. Final coat of wax in a couple of days.

Receiver markings

Markings for fire controls. green dot for safe, red dot for semi, two red dots for binary.

Bipod bridge

Fronsight, sling, bayonet assembly.

Solid trigger

Walnut butt stock and fore end finished in Danish Red Mahogany oil. Final coat of wax in a couple of days.

Last edited:

Two steps forward, one step back. Am re-doing the fore end for the fourth, maybe fifth time. It was too shallow to accept a full length bayonet. Also. the cooling slots weren't right and the top too thin for the cut ribbing. So, I decided to just build a new one. And, a new bayonet. I am down to Walnut scraps so am having to laminate pieces together...the same as the German's did. At least a laminated stock has many advantages, but it is time intensive.

Walnut scraps and slices of old butt stocks cut and glued together to make the new fore end.

Cerakoted the metal parts today. Here is the lower receiver getting its red and green enamel fire selection controls.

Attention to detail...even if it's non-functional detail. Stock take-down button.

Walnut scraps and slices of old butt stocks cut and glued together to make the new fore end.

Cerakoted the metal parts today. Here is the lower receiver getting its red and green enamel fire selection controls.

Attention to detail...even if it's non-functional detail. Stock take-down button.

Nearing completion. Finished the fourth and final iteration of the fore end. This one will accept the full size bayonet. On to the oil finish and then final assembly.

Made a more correct fire control selector.

Made a more correct fire control selector.

Finished. Exactly one month from start to finish. Shooting video to come.

One of the laminated pieces of Walnut was from a piece of exhibition grade wood I had left over.

Bayonet

One of the laminated pieces of Walnut was from a piece of exhibition grade wood I had left over.

Bayonet

Last edited:

Similar threads

Precision Rifle Gear

Chronograph Testing: Gun Mount vs. Static

- Replies

- 3

- Views

- 456

- Replies

- 8

- Views

- 2K