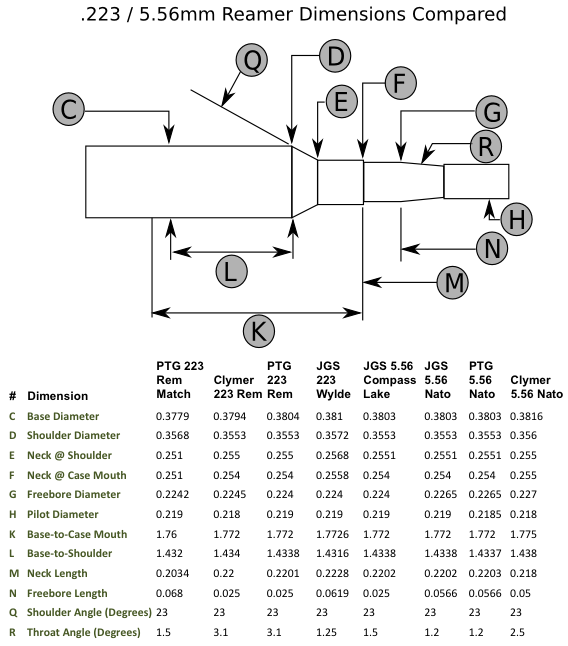

Just started reloading. Hornady classic press, have a 18" AR .223 wylde chamber. I was using some LC 223 brass from some remanufactured black hills with 77s, I succesfully loaded .308 using once fired Federal brass from gmmm. The bullets (Hornady 75 bthp) wouldnt seat in the neck, I would slowly adjust the die but most didnt seat, some did. I ended up smooshing a few of pieces of brass trying to get the neck tension needed. Is there a difference in 223 and 556 brass? Like dont load 223 brass using 556 powder charges? Is it my .223 wylde chamber causing the 223 brass to grow and not seat the bullet tightly? Was using 23gr of Varget just to start. A grain under hornadys max 223 load but it was under the service rifle 223 section in the Hornady book. I was using RCBS 308 dies and a new set of Hornady dies for 223. I also over lubed the 308 sizing die and got a case stuck in the die, any way to get it out?

Thanks im just starting out with all this.

Thanks im just starting out with all this.