Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oversized Barrel Extension Preventing Installation Of Barrel on Thermo Fitted Upper Receiver

- Thread starter Fire4EffectCA

- Start date

Doubt.Actually, none of the recommendations here were going to work with the first BCM M4 receiver I received. I spoke with another manufacturer of upper receivers and they stated I would have cracked the upper receiver if I proceeded any further as recommended here.

Technicians at BCM also confirmed the combination of the BCM M4 upper receiver I received and the barrel extension on the CLE barrel would not work. The barrel extension was 0.001” too large.

This is why BCM provided me with a replacement upper receiver with a barrel extension bore that was 0.001” larger than the first BCM M4 upper receiver. I followed BCM’s install instructions with the new receiver and I was able to install the CLE barrel in the BCM upper receiver.

I want to know who said the upper would crack.

So which BCM receiver do you have the Mk1 or mk2?

Mk2 is thermofit intentionally undersized

BCM’s mil-spec max diameter for a barrel extension is .9987” and that’s the max with which the BCM Mark 2 upper receivers are designed to fit with. Since my barrel extension measured 1.0000” at the index pin end it was 0013” over the max.

BCM went through their inventory and sent me an upper receiver that was at the high end of their specification which allowed the thermofit procedure to work.

BCM’s mil-spec max diameter for a barrel extension is .9987” and that’s the max with which the BCM Mark 2 upper receivers are designed to fit with. Since my barrel extension measured 1.0000” at the index pin end it was 0013” over the max.

BCM went through their inventory and sent me an upper receiver that was at the high end of their specification which allowed the thermofit procedure to work.

No offense but 0.0013 over size isn’t really a big deal. I literally did match up with 0.0046 over size (average measurements from 12 different point between receiver and extension) last week, it went fine.

No offense but 0.0013 over size isn’t really a big deal. I literally did match up with 0.0046 over size (average measurements from 12 different point between receiver and extension) last week, it went fine.

The interference fit was not .0013”. The size of the barrel extension exceeded BCM’s maximum of .9987” for a barrel extension by .0013”. BCM's maximum barrel extension diameter for their thermofit upper receiver is .9987”.

It did not. Your calipers are unable to accurately measure what you are claiming. Resolution does not equal accuracy. The fact is you may know within .002 or so of the actual dimension. That is if you were a machinist that used the tool daily and has a good feel.The interference fit was not .0013”. The size of the barrel extension exceeded BCM’s maximum of .9987” for a barrel extension by .0013”. BCM's maximum barrel extension diameter for their thermofit upper receiver is .9987”.

BCM was being kind by entertaining your numbers and offering a replacement. Even more so when you claim the barrel extension is oversized. I would have told you to take it up with CLE.

Wait is this you…..

Unable To Seat New Barrel In New BCM Upper Receiver > Build It Yourself > AR15.COM

Firearm Discussion and Resources from AR-15, AK-47, Handguns and more! Buy, Sell, and Trade your Firearms and Gear.

Oversized Barrel Extension Preventing Installation Of Barrel In Thermo Fitted Upper Receiver > Build It Yourself > AR15.COM

Firearm Discussion and Resources from AR-15, AK-47, Handguns and more! Buy, Sell, and Trade your Firearms and Gear.

LOL

Type bigger. It may convince us.

Sooooo what’s the measurement of your barrel extension and receiver?The interference fit was not .0013”. The size of the barrel extension exceeded BCM’s maximum of .9987” for a barrel extension by .0013”. BCM's maximum barrel extension diameter for their thermofit upper receiver is .9987”.

As JBoomhauer has explained calipers are not gonna work…well. Calipers will give you a rough idea or allow you to maybe see how things are trending “IF” you’re skilled like in the sense you’re doing this every day, then you might be able to get a way with it but honesty you’re gonna want a micrometer. And you’ll probably want to take measurements at multiple points along with the extension and the receiver bore. Often times I’ve found something like say a barrel extension is assumed by the laymen (no offense) to be a cylinder but actually can have some pronounced tapered and oblong features once you really get down into it.

Bottom line is I can’t imagine BCM is wildly below M16 TDP specs. Like I said I jammed a 0.9996 extension into a fairly under sized 0.9950 receiver (these again are rough averages) all it took was a few meaty taps from a plastic hammer, no cracked receiver.

Results are pretty not bad.

Assuming parts info the op posted is correct. I am a little surprised an oversized barrel extension would fit in a undersize thermofit lower. Because of both being purposely out of spec, I assumed there would be a no go due to tolerance stacking.

I actually find this really interesting

I actually find this really interesting

It did not. Your calipers are unable to accurately measure what you are claiming. Resolution does not equal accuracy. The fact is you may know within .002 or so of the actual dimension. That is if you were a machinist that used the tool daily and has a good feel.

BCM was being kind by entertaining your numbers and offering a replacement. Even more so when you claim the barrel extension is oversized. I would have told you to take it up with CLE.

Wait is this you…..

Unable To Seat New Barrel In New BCM Upper Receiver > Build It Yourself > AR15.COM

Firearm Discussion and Resources from AR-15, AK-47, Handguns and more! Buy, Sell, and Trade your Firearms and Gear.www.ar15.com

Oversized Barrel Extension Preventing Installation Of Barrel In Thermo Fitted Upper Receiver > Build It Yourself > AR15.COM

Firearm Discussion and Resources from AR-15, AK-47, Handguns and more! Buy, Sell, and Trade your Firearms and Gear.www.ar15.com

LOL

Type bigger. It may convince us.

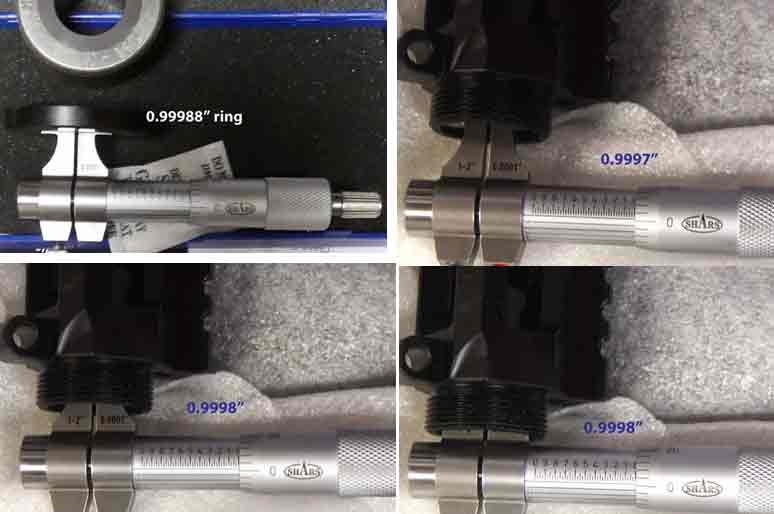

After my initial post I post I purchased a Mitutoyo micometer and confirmed my measurements with the Mitutoyo caliper were spot on. See attached photo.

Before my initial post here I had extensive conversations with Paul at Compass Lake about my options. Conrad did offer to buy the barrel back if it was not going to work for me, but I wanted to find a way to mount the barrel. BCM provided the solution and excellent support.

Attachments

Assuming parts info the op posted is correct. I am a little surprised an oversized barrel extension would fit in a undersize thermofit lower. Because of both being purposely out of spec, I assumed there would be a no go due to tolerance stacking.

I actually find this really interesting

You sir understand the issue perfectly.

0.0013" don't sound like much to me.

0.0046" sounds like A LOT.

I typically go for about 0.002", thermal slip fit.

220 to 240F for the receiver (oven), 4F for the barrel (freezer),

Spray on shim for about 0.002".

Both micrometers, inside/outside used are checked with blocks/rings.

0.0046" sounds like A LOT.

I typically go for about 0.002", thermal slip fit.

220 to 240F for the receiver (oven), 4F for the barrel (freezer),

Spray on shim for about 0.002".

Both micrometers, inside/outside used are checked with blocks/rings.

0.0013" don't sound like much to me.

0.0046" sounds like A LOT.

I typically go for about 0.002", thermal slip fit.

220 to 240F for the receiver (oven), 4F for the barrel (freezer),

Spray on shim for about 0.002".

Both micrometers, inside/outside used are checked with blocks/rings.

The mil-spec outside diameter of a barrel extension is 0.9987 -.0008/+0.0". I don’t know what BCM’s thermal slip fit spec is nor the variance for BCM’s forged upper receiver bores. If BCM’s thermal slip fit spec were .002” at 0.9987”, then the total thermal slip fit I was observing would be greater than .002”.

BTW, I did measure around 225˚F at the receiver bore before inserting the barrel extension, but I did not put the barrel in the freezer.

To clarify, what are the no shit actually dimensions of the barrel extension and receiver that you are attempting to fit?The mil-spec outside diameter of a barrel extension is 0.9987 -.0008/+0.0". I don’t know what BCM’s thermal slip fit spec is nor the variance for BCM’s forged upper receiver bores. If BCM’s thermal slip fit spec were .002” at 0.9987”, then the total thermal slip fit I was observing would be greater than .002”.

BTW, I did measure around 225˚F at the receiver bore before inserting the barrel extension, but I did not put the barrel in the freezer.

Reading back through the thread multiple times as I understand it you have a barrel and a receiver that aren’t going together but I can’t find you giving and actual measurements of those parts on hand.

I do see you referencing M16 TDP specifications (mil-spec) and possibly regurgitating what a company promises their dimensions are but I’ve measured enough barrel extensions and receivers to recognize that those specifications are simply the manufacturers “best intentions”. I always look at technical packages as contracts between the manufacturers and the customer, you trust its “xxxx +/- xxx” but it’s still prudent to verify.

What you get in real life is creating a specific and unique circumstance of tolerances. To crowd source more potential solutions for your circumstances (which is what I assume is the intention of this thread), it would be helpful to clarify you measurements and the tools used to gather them because (and I don’t think I am alone in this) it’s a little unclear based off the information you have provided so far.

Similar threads

- Replies

- 18

- Views

- 980

- Replies

- 22

- Views

- 2K

- Replies

- 15

- Views

- 3K

- Replies

- 165

- Views

- 27K

- Replies

- 16

- Views

- 3K