I’ve got a New Remington 700 308 win I picked up this winter and just got around to being able to shoot last weekend.

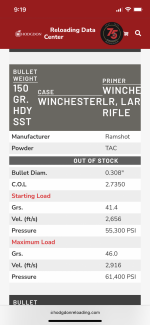

So far the only ammo to go through it are the reloads I’ve done for it. I was using data published from Hodgdon for Hornady SST 150gr and Ramshot Tac. The brass used was Starline LRP and the primers were Federal GM210M.

All the brass from the lowest charge to the highest either had ejector wipe, ejector ring or both. I also had some factory Hornady 150 SP that I chambered and pulled out without firing and that had ejector wipe on it as well. While closing the bolt with the reloads and the factory ammo, both feel heavier than what I think to be normal. Possible it’s the rifle, or due to the ejector wipe?

I’ve attached a few picture below.

The first photo is the 44 grain charge. You can see the ring around the “W” in win

The second photo is from the 43.6 grain charge and it starts at the “3 and goes towards the S and T where there is a ring”

In the third photo the factory Hornady ammo and it starts at the “ N in win and goes over to the N in Hornady”

Any insight would be greatly appreciated, thanks!

So far the only ammo to go through it are the reloads I’ve done for it. I was using data published from Hodgdon for Hornady SST 150gr and Ramshot Tac. The brass used was Starline LRP and the primers were Federal GM210M.

All the brass from the lowest charge to the highest either had ejector wipe, ejector ring or both. I also had some factory Hornady 150 SP that I chambered and pulled out without firing and that had ejector wipe on it as well. While closing the bolt with the reloads and the factory ammo, both feel heavier than what I think to be normal. Possible it’s the rifle, or due to the ejector wipe?

I’ve attached a few picture below.

The first photo is the 44 grain charge. You can see the ring around the “W” in win

The second photo is from the 43.6 grain charge and it starts at the “3 and goes towards the S and T where there is a ring”

In the third photo the factory Hornady ammo and it starts at the “ N in win and goes over to the N in Hornady”

Any insight would be greatly appreciated, thanks!

Attachments

-

ED72E8DC-F238-41FF-8486-582A8AF29447.jpeg317.7 KB · Views: 278

ED72E8DC-F238-41FF-8486-582A8AF29447.jpeg317.7 KB · Views: 278 -

98F5149D-A5FA-470F-8DF9-6958800EEA8A.jpeg324.7 KB · Views: 309

98F5149D-A5FA-470F-8DF9-6958800EEA8A.jpeg324.7 KB · Views: 309 -

9A947E4A-4E91-41FF-A709-68CF3D90A09A.jpeg308.8 KB · Views: 283

9A947E4A-4E91-41FF-A709-68CF3D90A09A.jpeg308.8 KB · Views: 283 -

23BE7521-4B1E-44D8-8263-1607ADF09499.jpeg517.2 KB · Views: 245

23BE7521-4B1E-44D8-8263-1607ADF09499.jpeg517.2 KB · Views: 245 -

3079D83A-926A-4BCF-813F-6881A12F89EF.png919.6 KB · Views: 280

3079D83A-926A-4BCF-813F-6881A12F89EF.png919.6 KB · Views: 280