Just removed a barrel from a thermal for upper. Little heat from a torch and a wooden dowel and it taps right out. Easy peasy.Everything I build the last 6 or so years has been thermal fit with a heat gun, I just haven’t messed with pulling a barrel yet. I did see someone mentioned a JP video so I’ll definitely check it out. I generally try to avoid a torch whenever possible..

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Precisions ar upper? Build help….

- Thread starter lycokayaker

- Start date

I use loctite high temperature bering sleeve on the barrel extension. Johnson paste wax in the reciever where it contacts the extension acting as a release agent ...when you want to seperate, no heat needed, just a (1" for AR 15 or 30 mm for AR 10) oak dowel machined down relief to fit the barrel extension, insert in reciever, hang on to barrel and slam oak dowel on the concrete floor, barrel begins to seperate from reciever...easy.

Here soon I will pull down my old X-Caliber 22N barrel and see how the spray on shim held up.

Over 5 years and about 3200 shots. New barrel about a month away.

A question I have about these Thermal Fit assemblies. How much Interference in I.D. vs O.D. do you end up with?

Any measurements to determine a little interference, medium, or a lot?

Since aluminum and steel have different coeficients of expansion, how warm (during shooting) do the parts have to be to lose that interference?

Thermal fit at shop temperatures, or thermal fit at range temperatures.

Probably doesn't matter as long as the assembly doesn't just slide together and wobble but how warm (with heat gun or torch) do you get the aluminum when you assemble?

With a tolerance range of both extension and receiver bore, wouldn't it be nice to know both dimensions, or even just the clearance before recommending different brands?

Shim stock can be used to check clearance before assembly when the parts slip together easily.

Only after you have an idea of degree of slop can you pick the right shim thickness for a real thermal fit at the range.

Any measurements to determine a little interference, medium, or a lot?

Since aluminum and steel have different coeficients of expansion, how warm (during shooting) do the parts have to be to lose that interference?

Thermal fit at shop temperatures, or thermal fit at range temperatures.

Probably doesn't matter as long as the assembly doesn't just slide together and wobble but how warm (with heat gun or torch) do you get the aluminum when you assemble?

With a tolerance range of both extension and receiver bore, wouldn't it be nice to know both dimensions, or even just the clearance before recommending different brands?

Shim stock can be used to check clearance before assembly when the parts slip together easily.

Only after you have an idea of degree of slop can you pick the right shim thickness for a real thermal fit at the range.

Last edited:

I have a few of the BCM MOD4 thermofit uppers here. I can measure the ID for you if that's what your looking for.... they do have to be heat up pretty good with an industrial heat gun to get them to slide in that's for sure...I don't use a torch.

It would be nice info.

If not too much trouble.

Just using calipers, 2 BCM uppers have an ID of 0.990

That's pretty darn small.Just using calipers, 2 BCM uppers have an ID of 0.990

Thanks.

Could you please explain where you put the wax?I use loctite high temperature bering sleeve on the barrel extension. Johnson paste wax in the reciever where it contacts the extension acting as a release agent ...when you want to seperate, no heat needed, just a (1" for AR 15 or 30 mm for AR 10) oak dowel machined down relief to fit the barrel extension, insert in reciever, hang on to barrel and slam oak dowel on the concrete floor, barrel begins to seperate from reciever...easy.

That's pretty darn small.

Thanks.

They are definitely a nice solid, tight fit in the 40+ I've used.... you aren't putting a barrel in there without heating it up good and even then I tap the upper on with a rubber mallet. Not with force, but I have to tap it on.

@ 13 microinches per degree F (7075) how hot do you have to get the receiver to allow a 1 inch extension to slip in?

Anyway, those are much tighter than my cheapo BCA uppers.

Being poor keeps me in the bargain bin

Last BCA side charger, with BCG, on sale.

But not near as good as the other brands and I have to shim.

Anyway, those are much tighter than my cheapo BCA uppers.

Being poor keeps me in the bargain bin

Last BCA side charger, with BCG, on sale.

But not near as good as the other brands and I have to shim.

Last edited:

This 100%. BCM is the only forged upper I would trust for a precision build. When you measure them, you realize why. Everything else has to be trued.Get a BCM thermofit upper and be done... or go MEGA if you want a thick billet upper....

I've used and have many AERO uppers and lowers....but I'll never use one again. The last 3 were out of spec to the point they were unusable....bolt.wouldnt line up with barrel, wouldn't fit on lower....took months to get Aero to handle....lots of excuses...finally 4 months later they sent me new parts. I sold them and never bought any again.

The good part for you is Craddock is building it so what you get will be tested and vetted...

You use the lapping tool. Quickly to realize if its needed or not.What is everyone's method other than visual inspection for determining if the face of the receiver needs to be lapped???

I've thought about using a flashlight to see if there's visible light around the edges or possibly an automotive feeler gauge but I have no idea what the appropriate size feeler gauge would be.

AR-15/M16 UPPER RECEIVER LAPPING TOOL | Brownells

Cold-rolled steel lapping tool chucks into a 3/8' hand drill to easily “square” the upper receiver face on your AR-15. Helps ensure precise mating of barrel and receiver for added accuracy. Coat face of receiver with aluminum-oxide lapping compoun...

I have the "Wheeler" lapping tool but it sure wouldn't fit in an upper that tight.

What's the diameter of the Brownell's one?

PTG does sell an undersize lapping tool.

pacifictoolandgauge.com

pacifictoolandgauge.com

What's the diameter of the Brownell's one?

PTG does sell an undersize lapping tool.

AR-15 Upper Receiver Lapping Tool - Pacific Tool and Gauge

AR-15 Upper Receiver Lapping Tool at Pacific Tool and Gauge

Last edited:

Zev, mega, bcm, Solgw… you get a thermal fit quality forged upper. Zev/Mega are the same now and they oem for Solgw

Keep an eye out for blems too. I wouldn’t use anything else these days.

It also means if you want to pull the barrel you need a press because they definitely will not slide out.

You can also add Icon Defense to the forged thermal fit camp. It’s basically the new Mega Arms, founded by Mike Miller, the OG founder of Maga Machine Shop before it got bought by ZEV. He’s also the designer of the Wedgelock and Drivelock rails. They’ve got some unique products in the works and the quality is top shelf. They are one of the few companies making BCG’s with integral gas keys and they have a new muzzle brake that is a two piece design that allows you to remove your gas block without unthreading your brake. They are also developing a fully ambidextrous lower. If you are OCD about gauging parts, Icon is definitely a company to keep your eye on.

Forged Upper Receiver Stripped - Icon Defense

Material: 7075 T6 Aluminum Coating: Type 3 Hard Coat Anodize Weight: 6.94 oz

Last edited:

Why would you not use an “enhanced”

Upper like Seekins/aero (same pattern) or Larue or a monolithic like Vltor?. When doing a precision upper ?

Upper like Seekins/aero (same pattern) or Larue or a monolithic like Vltor?. When doing a precision upper ?

@ 13 microinches per degree F (7075) how hot do you have to get the receiver to allow a 1 inch extension to slip in?

Anyway, those are much tighter than my cheapo BCA uppers.

Being poor keeps me in the bargain bin

Last BCA side charger, with BCG, on sale.

But not near as good as the other brands and I have to shim.

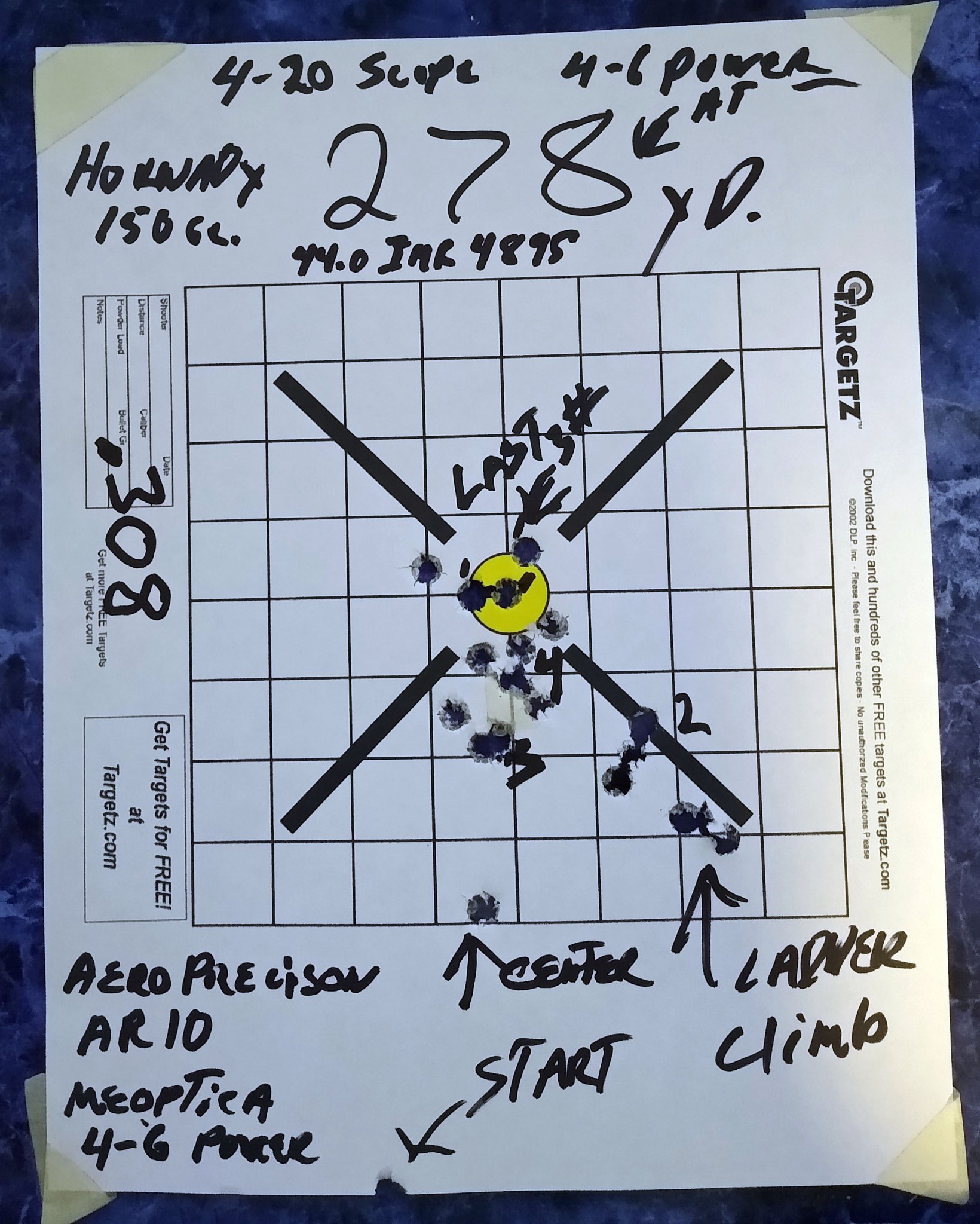

View attachment 8190395

Best deal out there.. I buy 5 at a time every 6 months or so....these are NOT bless. They say Demo and could be scratched but I've received every one looking brand new, in retail box with all parts...

BCM® Upper Receiver - M4 Flat Top (M4 Feedramps) Complete (Unassembled) - DEMO/Scratched

Fully Assembled, with round forward assist and ejection port cover, and T-Markings laser etched into receiver. This receiver has the M4 feedramps machined in.

Why would you not use an “enhanced”

Upper like Seekins/aero (same pattern) or Larue or a monolithic like Vltor?. When doing a precision upper ?

Depends use case, weight, etc. My dedicated 20" precision AR15's use MEGA billet slab side thick upper. Do you NEED this to achieve excellent accuracy? NO...but it doesn't hurt.

Why would you not use an “enhanced”

Upper like Seekins/aero (same pattern) or Larue or a monolithic like Vltor?. When doing a precision upper ?

I think that is a perfectly reasonable approach but you can get the same performance from a quality forged thermal fit upper and a very rigid rail.

As far as I know, LMT is the only company offering truly monolithic uppers.

I’ve been told that the semi monolithic uppers (where the rail bolts directly to the upper) are not more rigid than top of the line rails like the Drivelock because they usually use a thinner extrusion. I think Mike Miller said that the Drivelock is noticeably more rigid than the semi-monolithic uppers Mega used to make.

Last edited:

Wax the inside of the reciever bore where the barrel extension is to slide into with the loctite high temp bering sleeve glue on the extension.Could you please explain where you put the wax?

Give the location on the reciever bore a couple coats of Johnsons paste wax, and buff off...

Like a release agent the wax does not allow the glue to adhear to the reciever, but provides a very tight fit. Easy fit, no heat, but has the tight fit the barrel wont budge...Remove with oak dowel through the reciever, that butts up to the barrel extension...pound oak dowel hard on concrete floor, the barrel and reciever will begin to separate, hang on to the barrel with one hand, tap lightly as it begins to exit the reciever. No heat needed.

Here’s the upper craddock built me. Arrived Friday. Built on Aeros m4e1 enhanced upper

@cjs88 What work did Craddock do for assembly? Just assemble the parts or any truing, bedding, etc? They’re making my barrel right now, and I also planned to put it in an Aero enhanced upper. Curious to see your results.

Assembly and head spacing is all I believe. Never heard of trueing or bedding for an ar but I don’t follow that type of news.@cjs88 What work did Craddock do for assembly? Just assemble the parts or any truing, bedding, etc? They’re making my barrel right now, and I also planned to put it in an Aero enhanced upper. Curious to see your results.

Its pretty common practice, although I have ARs with none of it that shoot really well in receivers from BCM {blem}, RRA, and AR stoner.

Its pretty common practice, although I have ARs with none of it that shoot really well in receivers from BCM DEMO, RRA, and AR stoner.

Fixed

Any experience of Yankee Hill Machining billet receiver set? Im starting next AR15 build but have no idea YHM quality. I visited at the shop and tested 2 different barrel extension and one barrel into this billet upper but all 3 was sloppy in it and that surprising me little bit. Im living here in Skandinavia area so we have no so many choices to buy.

Thermo fit in a rifle with dissimilar metals, with vastly different heat expansion rates...could be problematic...depending on a lot of factors...like how much interference, exactly...and at what temperature it was assembled, and expected maximum operating temperature it is to preform at with respect to any loads applied...as still retain expected interference, to preform to standards...and what repeated excursions to high temperature have on the parts variable abilities to retain a certain fit range for extended periods.A question I have about these Thermal Fit assemblies. How much Interference in I.D. vs O.D. do you end up with?

Any measurements to determine a little interference, medium, or a lot?

Since aluminum and steel have different coeficients of expansion, how warm (during shooting) do the parts have to be to lose that interference?

Thermal fit at shop temperatures, or thermal fit at range temperatures.

Probably doesn't matter as long as the assembly doesn't just slide together and wobble but how warm (with heat gun or torch) do you get the aluminum when you assemble?

With a tolerance range of both extension and receiver bore, wouldn't it be nice to know both dimensions, or even just the clearance before recommending different brands?

Shim stock can be used to check clearance before assembly when the parts slip together easily.

Only after you have an idea of degree of slop can you pick the right shim thickness for a real thermal fit at the range.

Most can not measure accurately enough. Long parts will drastically expand out of print if moved from a temperature controlled room, machined to print there and measured in an 85° shop floor. A hole and shaft of the same dia, at the same temperature will not assemble, without pressure applied. So everything above the interference, is a press fit. Real precision is measured on CMM s and controlled temperature environment in a clean room with temperature stabilized parts...to meet engineering standards demanded.

This is backyard auto mechanics by comparison, every assembly different, with a little dirt, grease, and sweat mixed in.

Appears as more of a selling gimmick than actual performance enhancement, cause the fits are all different, requiring vastly different amounts of pressure to assemble. There were barrel extensions of different OD sizes available at one time, to get a "better" fit. I think a snug fit is desirable,... But is the heating and beating variable the best answer? How much is your reciever stressed? Does that affect accuracy negatively?...Or, It's really tight, so, it must be better? Right?

While temperature controlled rooms (68F?) might be good, normal temperature of use (either calculated from known coefficents or measured in-situ) is normally required for precision parts. Aircraft parts, auto engines, rocketship parts have to work at realistic temperatures.

Stress imparted on an tight fitting aluminum receiver over a steel extension decreases as the parts warm up.

It's obvious that most AR parts aren't made to be precision fitted as most assemblers don't even know the dimensions of the parts they are putting together.

Tight fit, loose fit, blue goo or shims.

Stress imparted on an tight fitting aluminum receiver over a steel extension decreases as the parts warm up.

It's obvious that most AR parts aren't made to be precision fitted as most assemblers don't even know the dimensions of the parts they are putting together.

Tight fit, loose fit, blue goo or shims.

Just get a PRI upper, put a lower and an optic on it and go.

My padawan shoots out to 800 with his with zero issues.

My padawan shoots out to 800 with his with zero issues.

Nothing wrong with Aero uppers or lowers ,better barrels can be had . It's the prices which makes one stop and consider VALUE=$$$'s .

I was dialing My scope in ,which normally I'd do at 165 yd. ,however had targets setup for 6.5 CM zeroing and was using run of the mill .308 loads

I was dialing My scope in ,which normally I'd do at 165 yd. ,however had targets setup for 6.5 CM zeroing and was using run of the mill .308 loads

Anyone know if Icon is planning on releasing a semi-monolithic, and if there thick walled receivers?

Similar threads

- Replies

- 0

- Views

- 160

- Replies

- 22

- Views

- 1K

- Replies

- 1

- Views

- 642