Re: Primer Pin Whole

<span style="color: #006600">Following this thread and not asserting my opinion to the original poster, but to others who might be following it too.

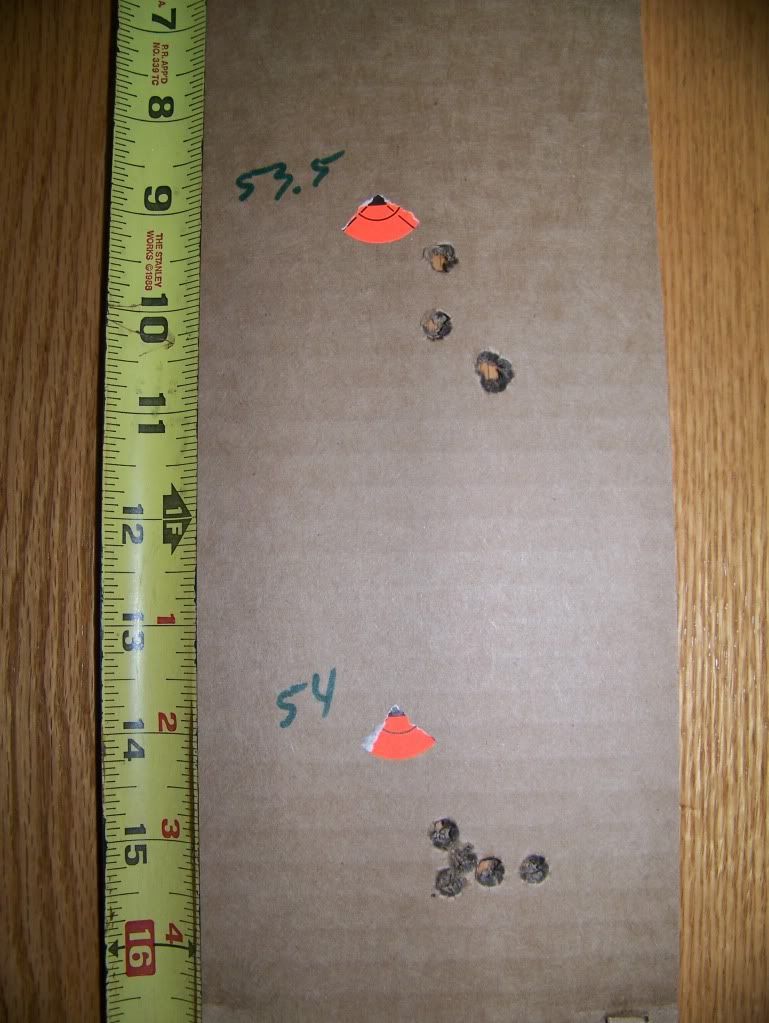

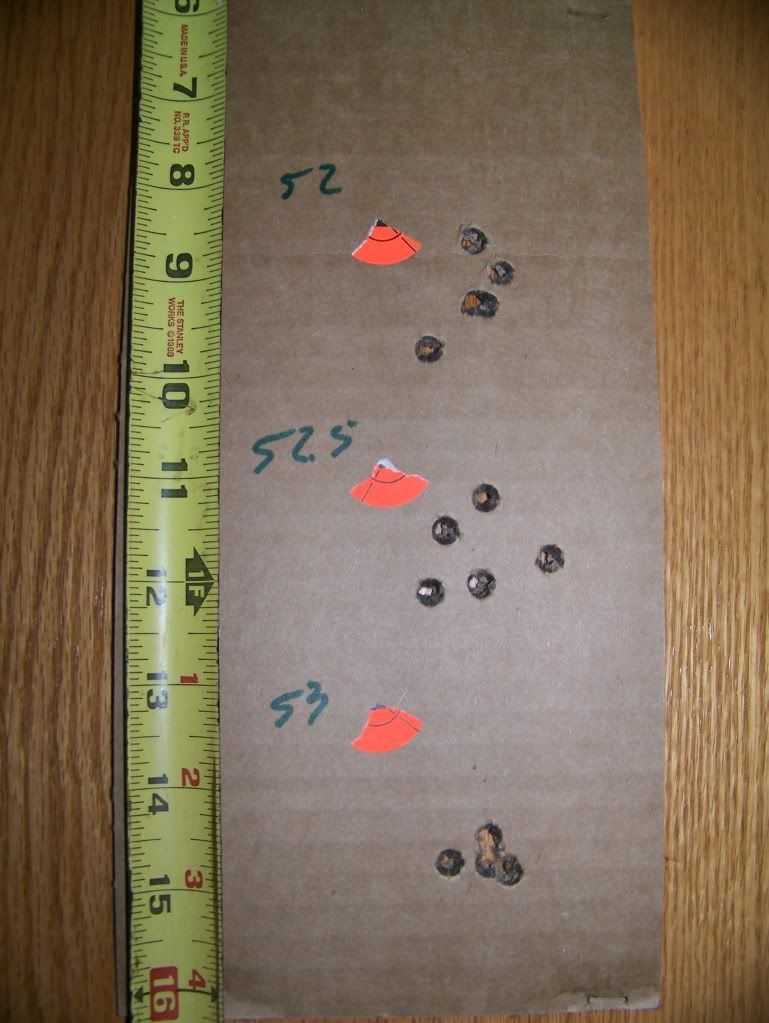

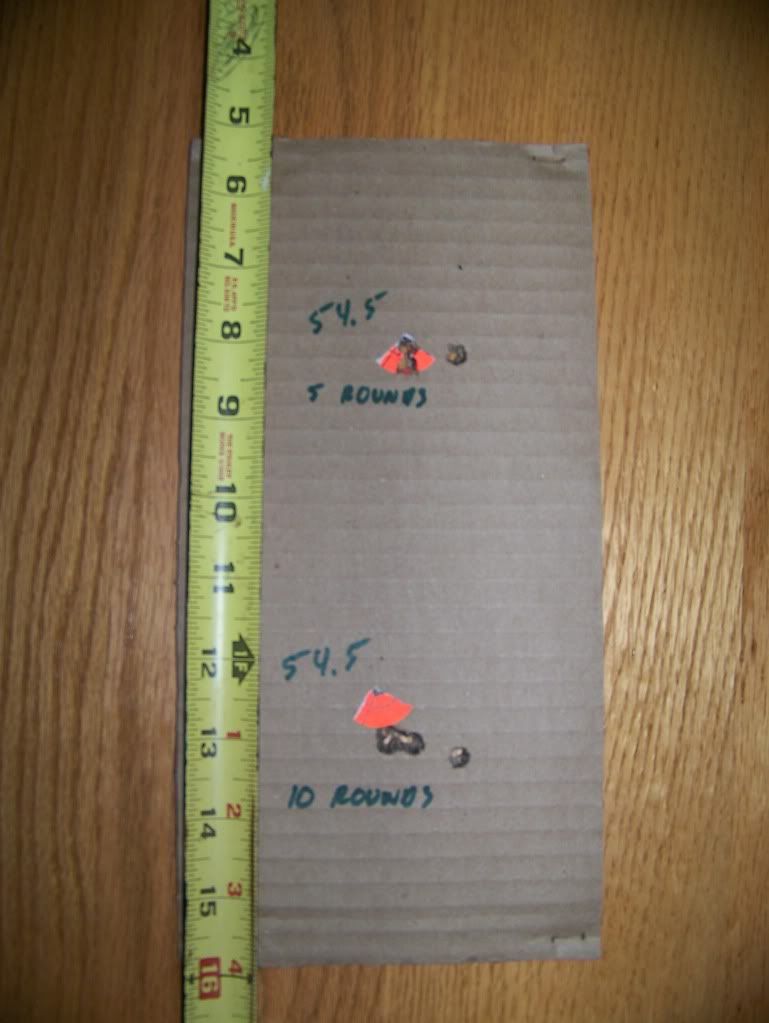

Even if the primer issue is ignored, the case head imprints from the bolt face show excessive pressure whose source is whatever it is, and regardless of the other examples of primer failure with loads that are not near maximum charge, the .284 Winchester loads pictured are too hot.

However, except for the failed primer, the 300 Win Mag case head shown does not appear to show signs excessive pressure, clearly in contrast to the .284 Winchester case.

This problem illustrates why load manuals set out a range of possible charge weights that mean at some point within the range of charge weights tested a loader might find an acceptable charge weight that shoots well in THAT rifle, THAT day, using THAT case brand, primer, propellant, barrel, chamber, bolt headspace....... ad nauseum. Loading ammunition is an experiment.

Noting again the original poster did not solicit advice, but others reading the thread might want it anyway. Several matters could cause excessive pressure in loads shown by the manual to be moderate ones. Bolt lubricant can migrate from the bolt lugs and body to rounds in the magazine or otherwise and then to the chamber. Liquids do not compress well. The chamber throat could be too small for the brass cases. The loader's scale could be defective or not set right. A step in the loading process could be defective. The reasons could go on.

The 300wm cases in this thread do not show excessive pressure except for the primer that failed, but the 284win case shown indeed shows excessive pressure in addition to the primers that failed.</span>

<span style="color: #006600">Following this thread and not asserting my opinion to the original poster, but to others who might be following it too.

Even if the primer issue is ignored, the case head imprints from the bolt face show excessive pressure whose source is whatever it is, and regardless of the other examples of primer failure with loads that are not near maximum charge, the .284 Winchester loads pictured are too hot.

However, except for the failed primer, the 300 Win Mag case head shown does not appear to show signs excessive pressure, clearly in contrast to the .284 Winchester case.

This problem illustrates why load manuals set out a range of possible charge weights that mean at some point within the range of charge weights tested a loader might find an acceptable charge weight that shoots well in THAT rifle, THAT day, using THAT case brand, primer, propellant, barrel, chamber, bolt headspace....... ad nauseum. Loading ammunition is an experiment.

Noting again the original poster did not solicit advice, but others reading the thread might want it anyway. Several matters could cause excessive pressure in loads shown by the manual to be moderate ones. Bolt lubricant can migrate from the bolt lugs and body to rounds in the magazine or otherwise and then to the chamber. Liquids do not compress well. The chamber throat could be too small for the brass cases. The loader's scale could be defective or not set right. A step in the loading process could be defective. The reasons could go on.

The 300wm cases in this thread do not show excessive pressure except for the primer that failed, but the 284win case shown indeed shows excessive pressure in addition to the primers that failed.</span>