I did not get much solid info before buying this unit. It came up as being sold as used and I grabbed it for €200 (€315 in stores here)

I have now handled around 50 6.5CM and 20 556 cases with it but I feel I can already speak for it.

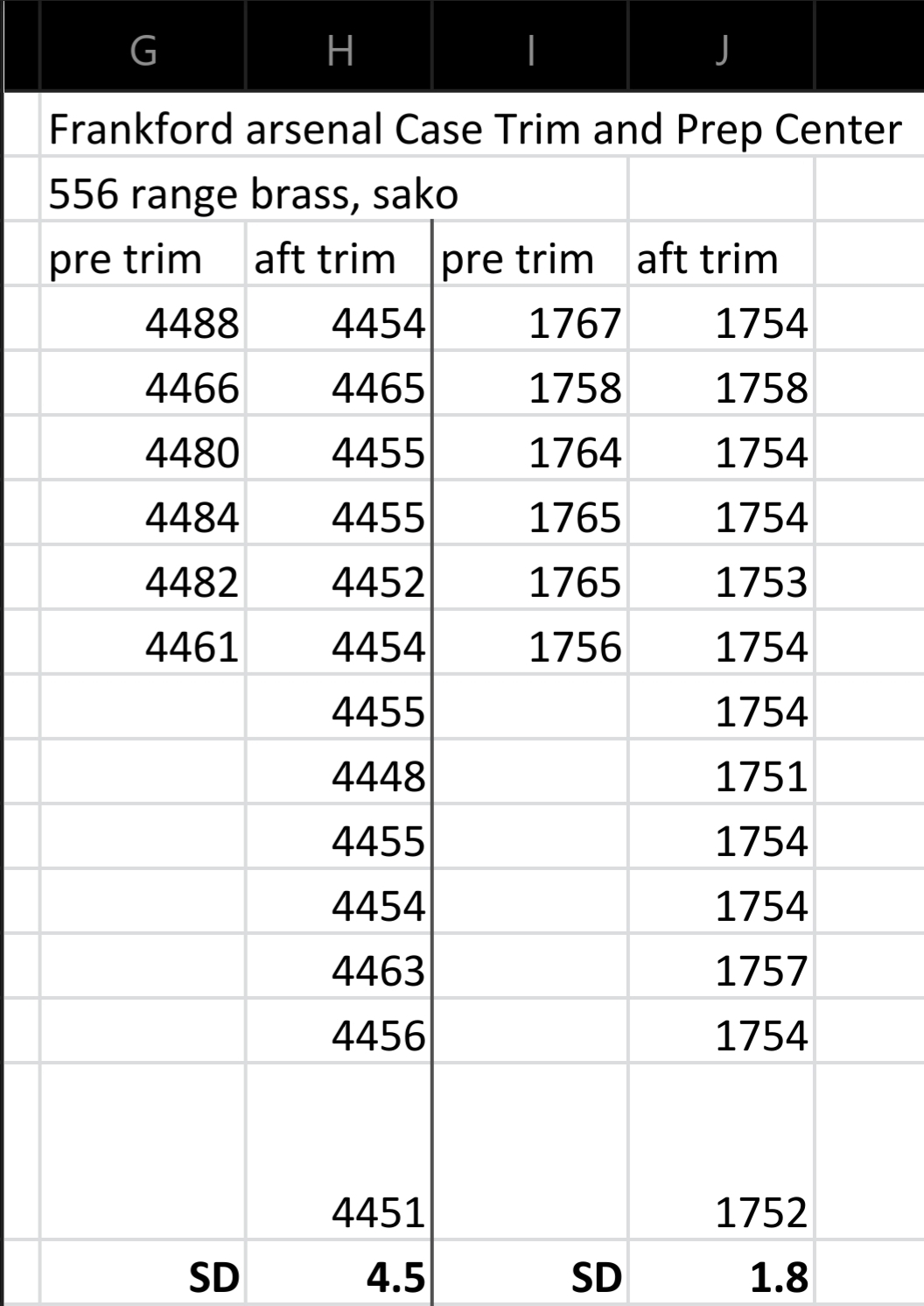

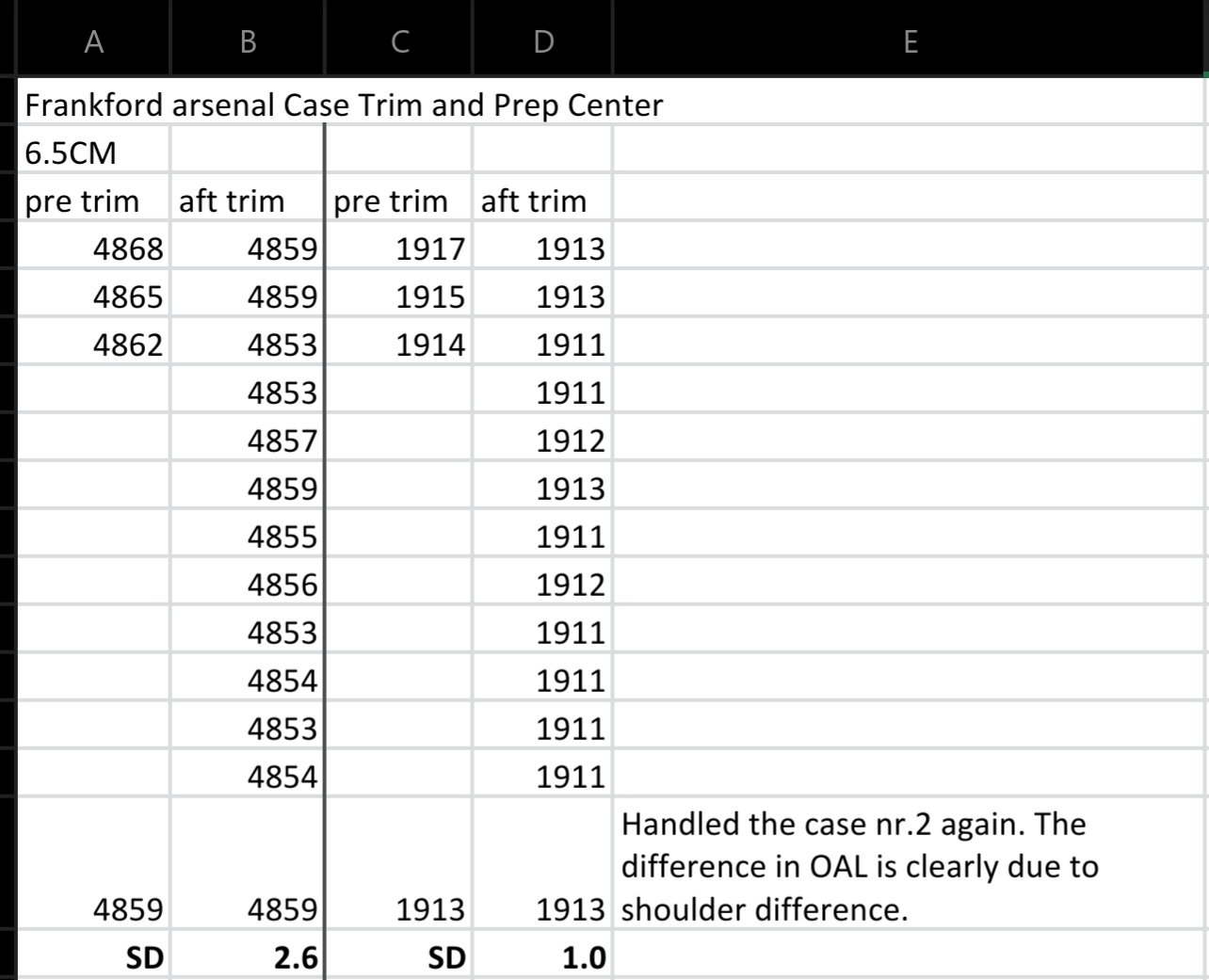

Around the web I saw many commenting it did not trim well. I documented my case lengths to investigate how true this was.

Overall, I like the machine. I was very worried about the seemingly wonky trimmer blade but I realized that no blade can be 100% straight towards the shell and twisting the shell is required in all use cases.

The blades do solid work and I get work done in one single step.

Here are my short findings about the trimmer:

What I did before using was polish the shell neck indexers so twisting the case does not cause any marks. I used paste and 24k polishing cloth for 6.5cm and just few wipes with polishing cloth on the 223 indexer. I do however polish nearly all my reloading gear where brass meets metal.

I have now handled around 50 6.5CM and 20 556 cases with it but I feel I can already speak for it.

Around the web I saw many commenting it did not trim well. I documented my case lengths to investigate how true this was.

Overall, I like the machine. I was very worried about the seemingly wonky trimmer blade but I realized that no blade can be 100% straight towards the shell and twisting the shell is required in all use cases.

The blades do solid work and I get work done in one single step.

Here are my short findings about the trimmer:

What I did before using was polish the shell neck indexers so twisting the case does not cause any marks. I used paste and 24k polishing cloth for 6.5cm and just few wipes with polishing cloth on the 223 indexer. I do however polish nearly all my reloading gear where brass meets metal.

Last edited: