So I finally sat down yesterday and played around with QL some more trying to get the output data to better track my chronograph results across several different load development efforts and now I find I have more questions than answers.

My starting assumptions: CED M2 chrono, Varget powder, 4 different bullet types (175/168 SMKs, 168 AMAX, and 185 Berger BTHPLR), and two different brass makes (Lapua and WIN). I have lots of chrono data for all of the above after doing ladder tests and I plugged them into an excel spreadsheet to then compare to QL. I meticulously measured the level water capacity of the brass per the QL instructions and then ran all my loads through QL to see what I got. QL was very close on some loads and just in the ballpark on others. Sometimes I was under 10 fps and other times the QL varied by up to 20-40 fps.

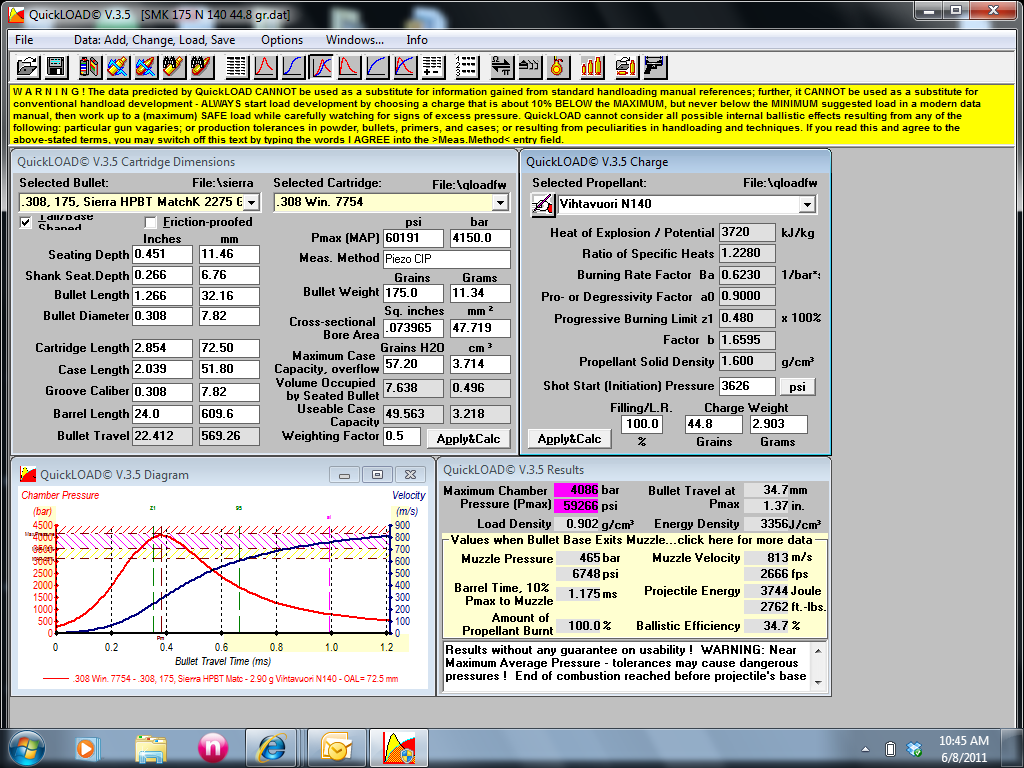

So I played with both the burn rate factor as well as the starting pressure. By manipulating one or the other, I could get a specific load to track one ladder test for a specific bullet and brass type. But as soon as I changed one or the other

(bullet or brass type) the QL results would no longer track.

I thought I would get the better results by playing with the burn rate factor (Ba) but I actually got closer with the starting peak pressure field. However, I think that field depends too much on the seating depth and is only going to work for one specific bullet and seating depth.

Anyway, sorry for the novel..... I'm starting to become disenchanted with QL. If it doesn't track real world data, what is the point? My understanding is it's designed to be a "predictive" tool. But I'm not sure I can trust it completely. Is it designed to just get you in the ballpark for truncating load development but you still have to do OCW or ladder tests to get the real answer?

So here are the specific questions:

1 - how do you guys use QL?

2. - how much tolerance or slop in MV is acceptable?

3 - how close do QL OBT numbers have to the OBT chart to be considered "on the node"?

Thanks in advance for any insight and help.

My starting assumptions: CED M2 chrono, Varget powder, 4 different bullet types (175/168 SMKs, 168 AMAX, and 185 Berger BTHPLR), and two different brass makes (Lapua and WIN). I have lots of chrono data for all of the above after doing ladder tests and I plugged them into an excel spreadsheet to then compare to QL. I meticulously measured the level water capacity of the brass per the QL instructions and then ran all my loads through QL to see what I got. QL was very close on some loads and just in the ballpark on others. Sometimes I was under 10 fps and other times the QL varied by up to 20-40 fps.

So I played with both the burn rate factor as well as the starting pressure. By manipulating one or the other, I could get a specific load to track one ladder test for a specific bullet and brass type. But as soon as I changed one or the other

(bullet or brass type) the QL results would no longer track.

I thought I would get the better results by playing with the burn rate factor (Ba) but I actually got closer with the starting peak pressure field. However, I think that field depends too much on the seating depth and is only going to work for one specific bullet and seating depth.

Anyway, sorry for the novel..... I'm starting to become disenchanted with QL. If it doesn't track real world data, what is the point? My understanding is it's designed to be a "predictive" tool. But I'm not sure I can trust it completely. Is it designed to just get you in the ballpark for truncating load development but you still have to do OCW or ladder tests to get the real answer?

So here are the specific questions:

1 - how do you guys use QL?

2. - how much tolerance or slop in MV is acceptable?

3 - how close do QL OBT numbers have to the OBT chart to be considered "on the node"?

Thanks in advance for any insight and help.