If you really just want to try stuff, go get some HSS blanks and grind your own bits. I go through and buy a few and always have 5-6 blanks on hand. Never know when they will come in handy. Plus being able to grind your own bits can save your bacon if you break your last insert at 6pm on a friday and you have project you want to get done to take out on saturday. Also, when cutting aluminum its really nice to be able to make them razor sharp with the proper geometry to cut well or if you need to cut some delrin you can get a glass like finish with out having to try, where as most carbide inserts for steel suck in both Aluminum and plastic.

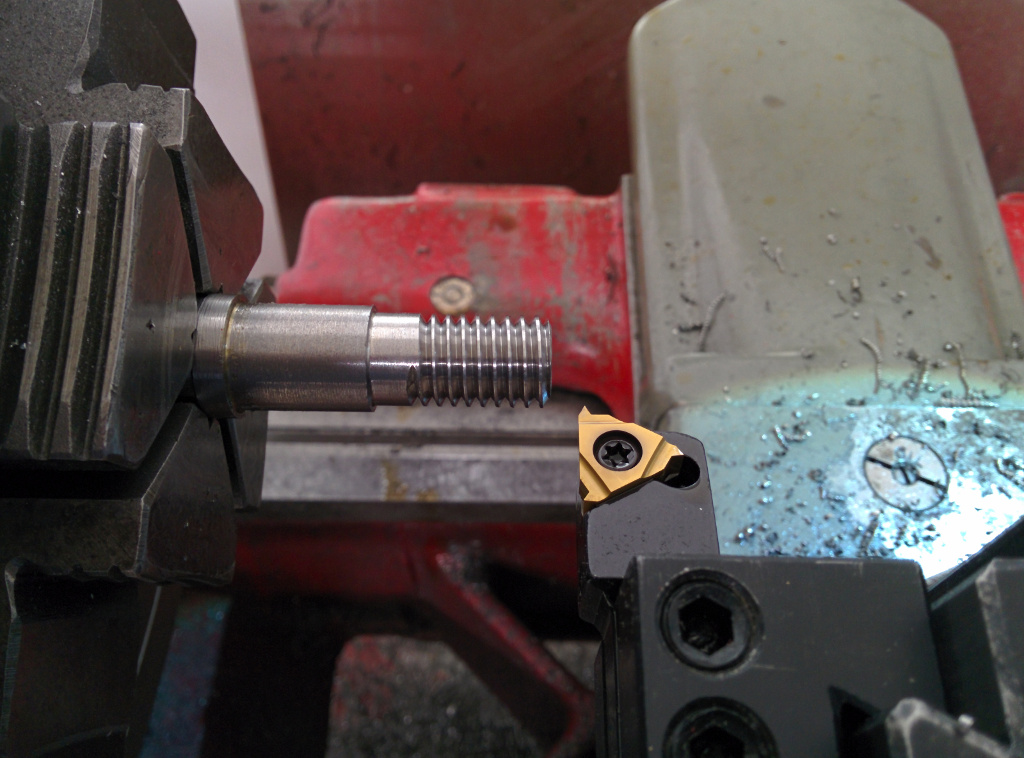

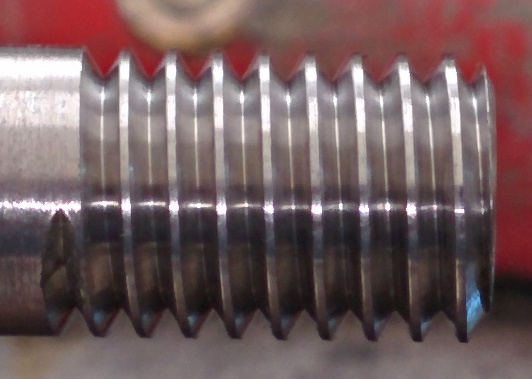

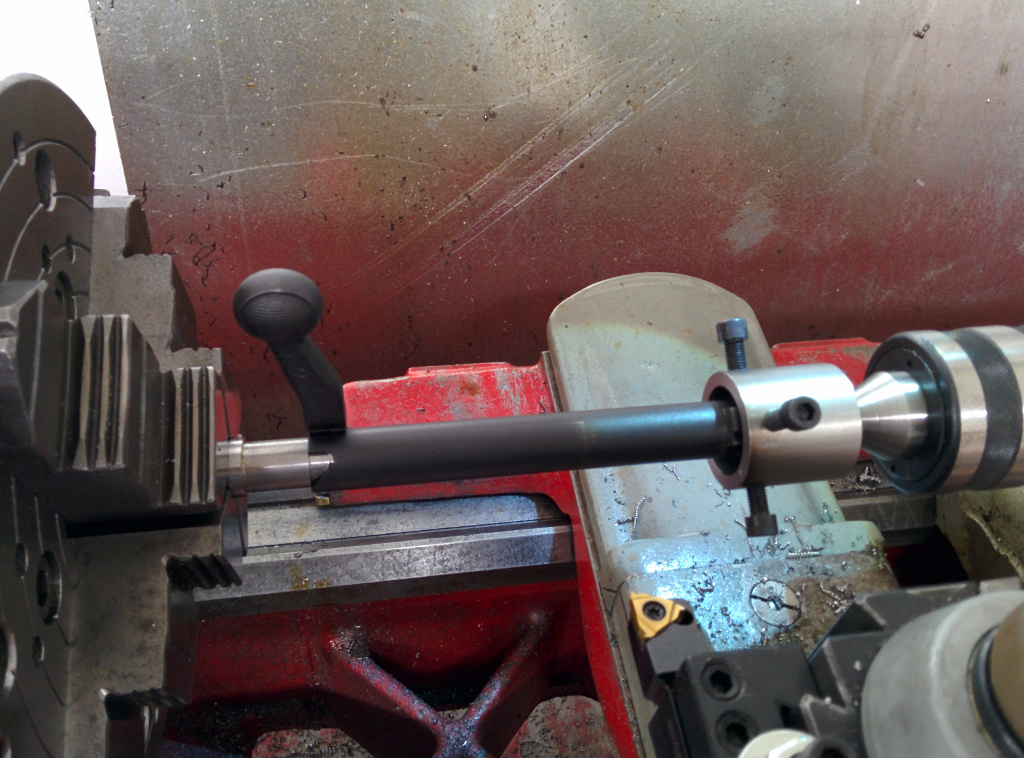

That said, insert tooling is nice. Carbide will outlast HSS by quite aways. And it looks like you have a couple good holders there. The trick is figuring out what inserts for what material. I took a free course and got a nice book from sandvik about metal cutting technology and a bunch of fancy business on tool geometry etc. Was really helpful. Here is a

link to it. Its quite helpful, even if it is heavily biased to their stuff (shocking, I know). Shars has some ok imported stuff. Good bang for you buck if you are on a budget. I would steer clear of MSC and Enco. I have always gotten better prices on comparable if not the same tooling from local vendors. I may pay slightly more going with the local guy, but I can hop over there in about 30min and have it same day.

2 more things: DRO's are worth their weight in Myrrh. Speed things up a ton. If you can swing it, get one. 2nd, get a copy of the Machinery's Handbook if you don't have one already. Invaluable, especially the chapter about deciphering the Alphanumerics of insert codes.