Reloading For The AR-15: Swaging Primer Pocket Crimps

In order to reload brass cases that have crimped primer pockets, the crimp must first be removed before a new primer can be seated. There are two basic methods used to achieve this; reaming or swaging.

With reaming, you’re removing material from the case head. With swaging, you’re simply pressing material back into its original position. Of the two methods, my personal preference is for swaging with the Dillon Super Swage 600. The Dillon Super Swage returns the primer pocket more closely to its original condition than any of the other stand-alone tools that I’ve seen used to remove the primer pocket crimp.

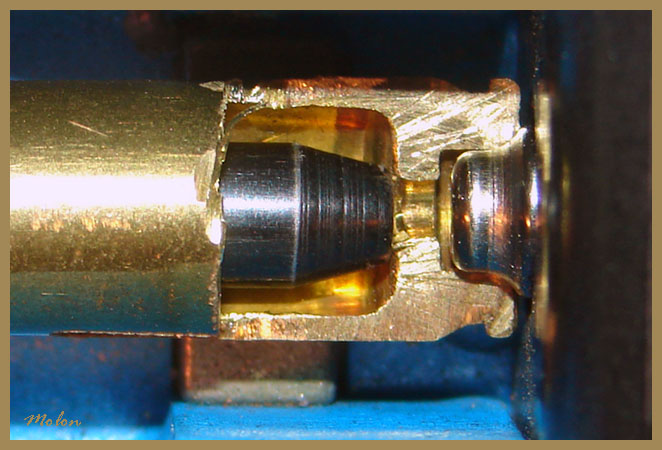

The pic below, with a cut-out 223 Remington case in the Super Swage, shows the swaging rod and the case positioning rod to give you an idea of just how the Super Swage works.

The next pic shows the case head of a factory-loaded round that has a crimped primer.

Now, a deprimed case . . .

The case from the above pic that has had the primer pocket swaged with the Super Swage . . .

And a pic with the same case reprimed . . .

This last pic shows the factory-loaded round next to the reprimed case for easy comparison.

…

In order to reload brass cases that have crimped primer pockets, the crimp must first be removed before a new primer can be seated. There are two basic methods used to achieve this; reaming or swaging.

With reaming, you’re removing material from the case head. With swaging, you’re simply pressing material back into its original position. Of the two methods, my personal preference is for swaging with the Dillon Super Swage 600. The Dillon Super Swage returns the primer pocket more closely to its original condition than any of the other stand-alone tools that I’ve seen used to remove the primer pocket crimp.

The pic below, with a cut-out 223 Remington case in the Super Swage, shows the swaging rod and the case positioning rod to give you an idea of just how the Super Swage works.

The next pic shows the case head of a factory-loaded round that has a crimped primer.

Now, a deprimed case . . .

The case from the above pic that has had the primer pocket swaged with the Super Swage . . .

And a pic with the same case reprimed . . .

This last pic shows the factory-loaded round next to the reprimed case for easy comparison.

…

Last edited: