I attended one of Bryan Litz's seminar last year. He gave an excellent presentation on cleaning a rifle barrel.

Using a borescope and possibly other equipment, he and his team discovered that using a mechanical means to get copper fouling out of a barrel exceeded that of the chemical variety.

If I recall correctly, that surprised Bryan. It surprised some of us listening to his presentation.

Before I left my .22-250 with the gunsmith to get re-barreled, the first 5-10 shots from a perfectly clean bore were 1.5-2 inch groups. It sucked.

However, after the barrel was fouled, it would settle down to 1/2" groups.

I had several thousand rounds to shoot up in a short amount of time because I want to get a 6.5 CM barrel in place of the .22-250. Keep in mind that I would never treat a barrel like this but I don't care as it is getting trashed anyway.

I spent several days recently shooting over 300 rounds a day through that thing. I wasn't shooting like my life depended on it, such as defending a hill in Korea from hordes of ChiCom troops. However, I didn't wait too long between shots either. Doing the math, I was probably shooting with an average of 1.5 minutes between shots or 40 shots per hour over the course of the day.

When the image in the scope got too blurry because of the barrel and suppressor heat, I let it cool for about 10-15 minutes. It was still pretty darn hot after the rest period. That was with a string of 10-20 shots; one right after another.

Until the image got blurry because of barrel and suppressor heat, I was amazed at how accurate that rifle was to it's effective range of about 700 yards.

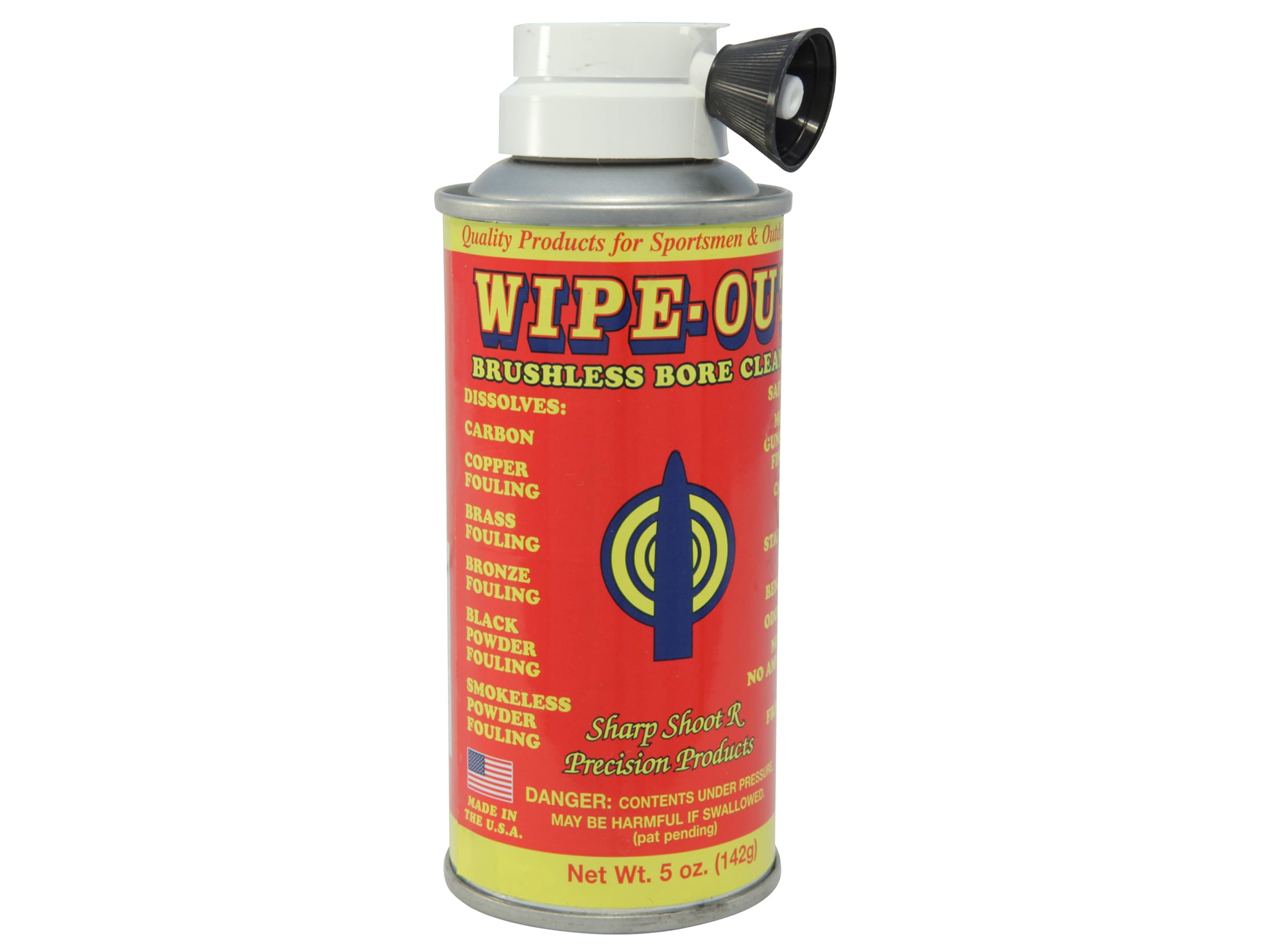

At the end of the day all I did for cleaning was put bore solvent on the brush of a bore snake and CLP on the tail. Then I pulled it through the barrel one time. BTW, Hoppes recommends that technique; once through the barrel.

Then the next time that I went to the range, the bullets landed where I wanted them to. I was amazed at how much punishment that barrel could take and still hit a steel coyote at 650 yards.

Back when my eyes were better with 20/10 vision, I had a 1917 Enfield with a heavily pitted barrel. Because of a marriage to Medusa, I had to sell the rifle.

Now you would think that a heavily pitted barrel could not hit anything but I use to be able to hit 5" X 7" plates at 300 yards easily with that rifle and ball ammo. It surprised everyone seeing me do it. Heck, I was even surprised!

I say all this because, like women, I don't think we'll ever be able to figure out some of the mysteries of rifle barrels.