Hi every body! I have just recently done some of my own gunsmithing work and thought I would wite a post with some pictures. First let me tell you a little about myself. My name is Mike, I'm 23, I have attended school for Precision CNC and Manual machining, I have been a shooting enthusiast for about 15 years now thanks to my father and I plan on being a gunsmith when I grow up

NOW to show and tell!

After learning a mouth and a gut full at school and picking my buddy's brain (Keith J. @ AZPRECISION) I had decided to true/blueprint both my Remington 700SA and my HOWA 1500SA. Before I could do this I had to make a few fixtured that would allow me to to indicate the actions off the bolt raceway as well as to indicate the bolt. Chambering will be done soon but thats for another time.

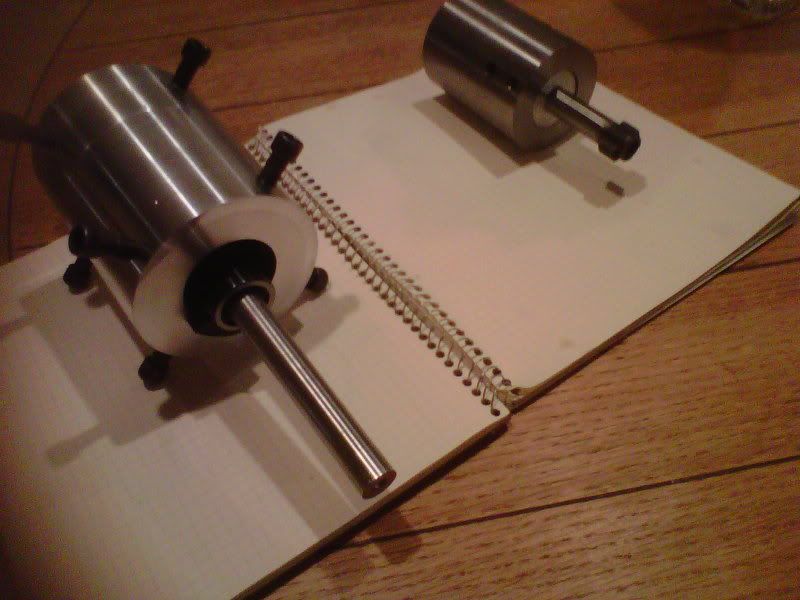

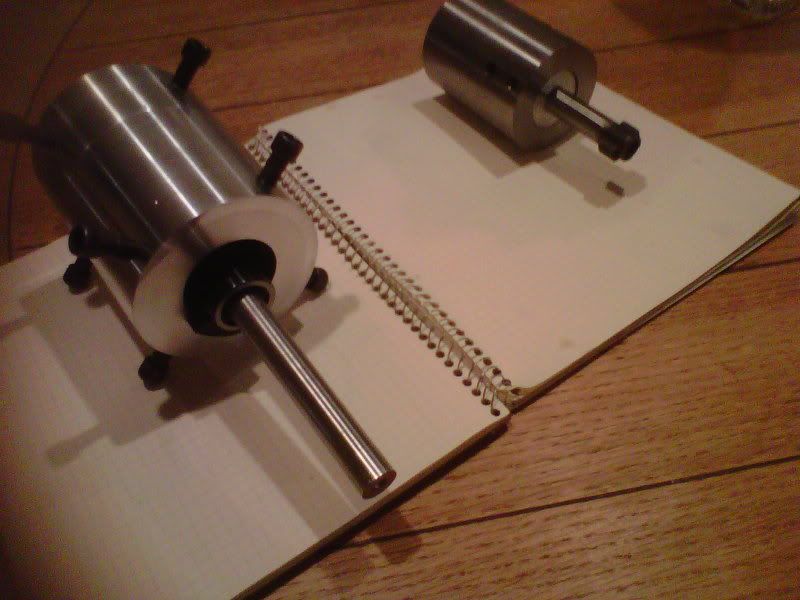

The first jig I made (FAR LEFT in picture). Fits any non-flat based action,Remy,Savage or similar. The second jig(MIDDLE in picture) will fit any non-flat action as well as pretty much any type of bolt.The third jig (FAR RIGHT) will fit most flat bottom action w/ or w/out a integral lug such as the Howa, Mauser or similar.

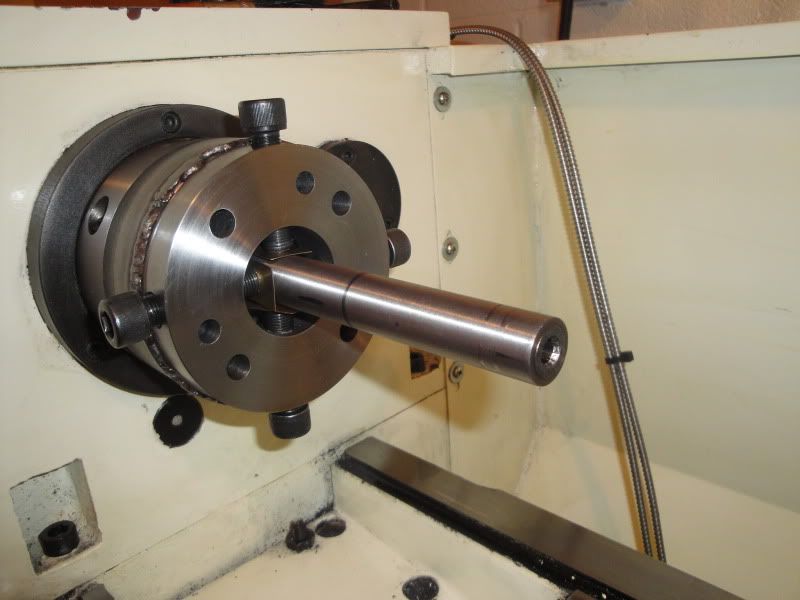

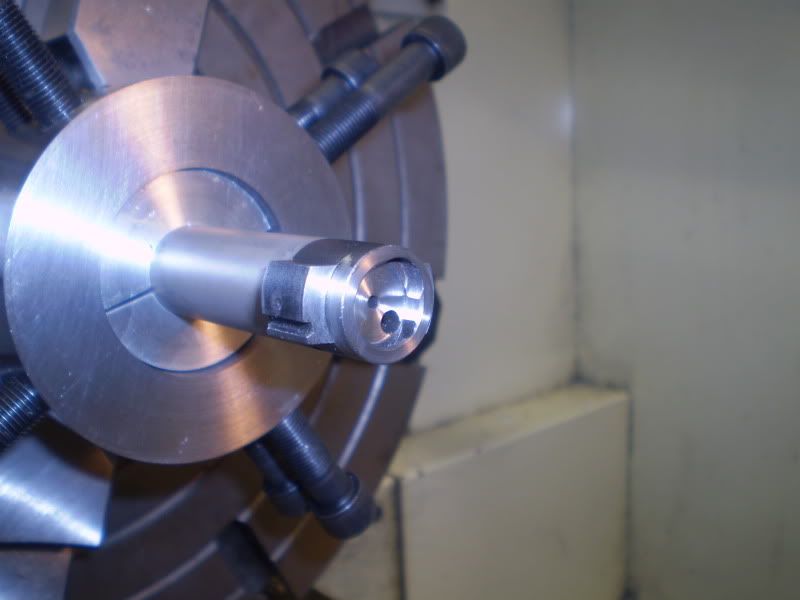

Here is the remington bolt in the spider before/ready for truing

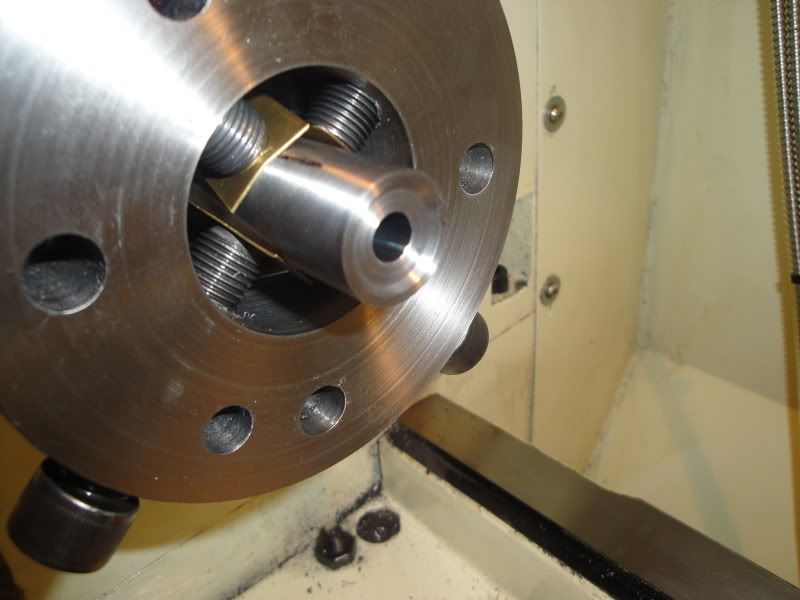

AFTER truing (rear/front of lugs,bolt nose and face)

Here is the finished product. Remginton action/bolt trued. It seems as thoughI forgot to get pictures of the action work but...the action was indicated in, lugs,face and threads were trued.

Here is the HOWA1500 and bolt awaiting truing

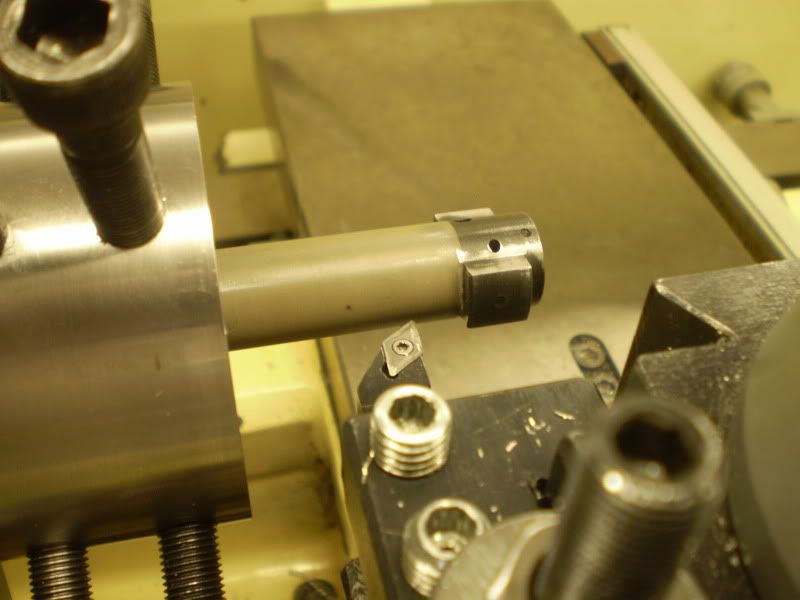

Here is the HOWA set up ready for truing and after cuts were made.

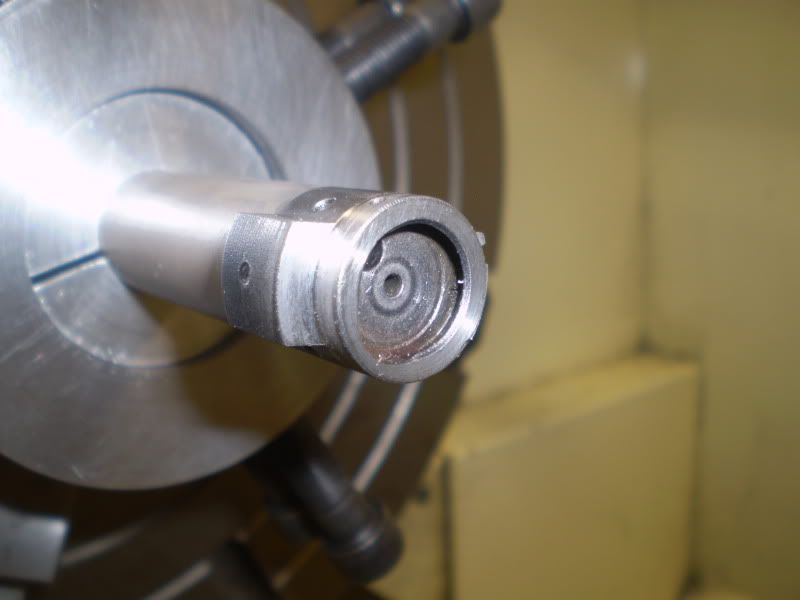

HOWA Bolt ready for truing.

HOWA action/bolt ready for assembly.

Thanks for looking!

NOW to show and tell!

After learning a mouth and a gut full at school and picking my buddy's brain (Keith J. @ AZPRECISION) I had decided to true/blueprint both my Remington 700SA and my HOWA 1500SA. Before I could do this I had to make a few fixtured that would allow me to to indicate the actions off the bolt raceway as well as to indicate the bolt. Chambering will be done soon but thats for another time.

The first jig I made (FAR LEFT in picture). Fits any non-flat based action,Remy,Savage or similar. The second jig(MIDDLE in picture) will fit any non-flat action as well as pretty much any type of bolt.The third jig (FAR RIGHT) will fit most flat bottom action w/ or w/out a integral lug such as the Howa, Mauser or similar.

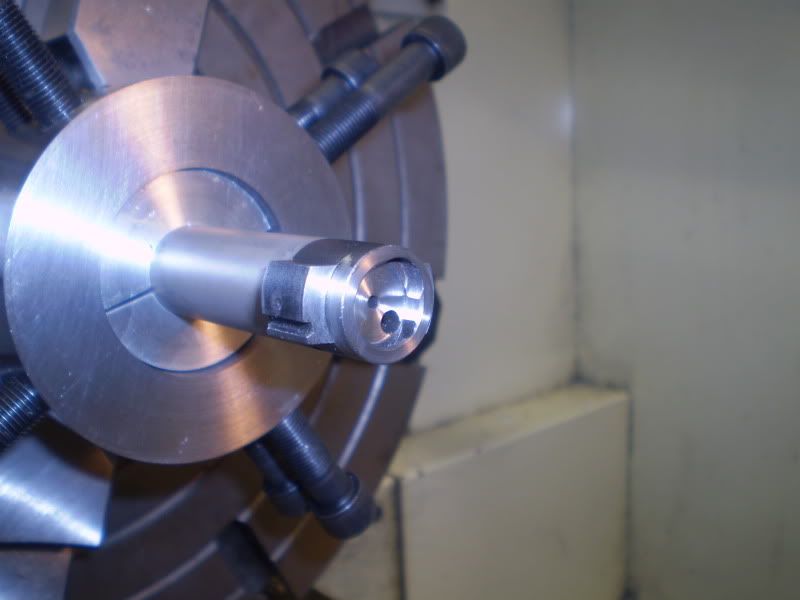

Here is the remington bolt in the spider before/ready for truing

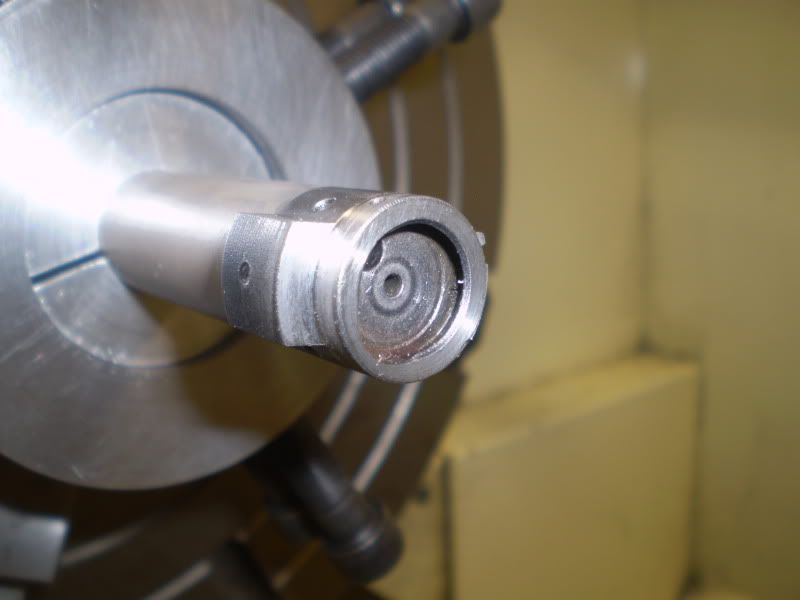

AFTER truing (rear/front of lugs,bolt nose and face)

Here is the finished product. Remginton action/bolt trued. It seems as thoughI forgot to get pictures of the action work but...the action was indicated in, lugs,face and threads were trued.

Here is the HOWA1500 and bolt awaiting truing

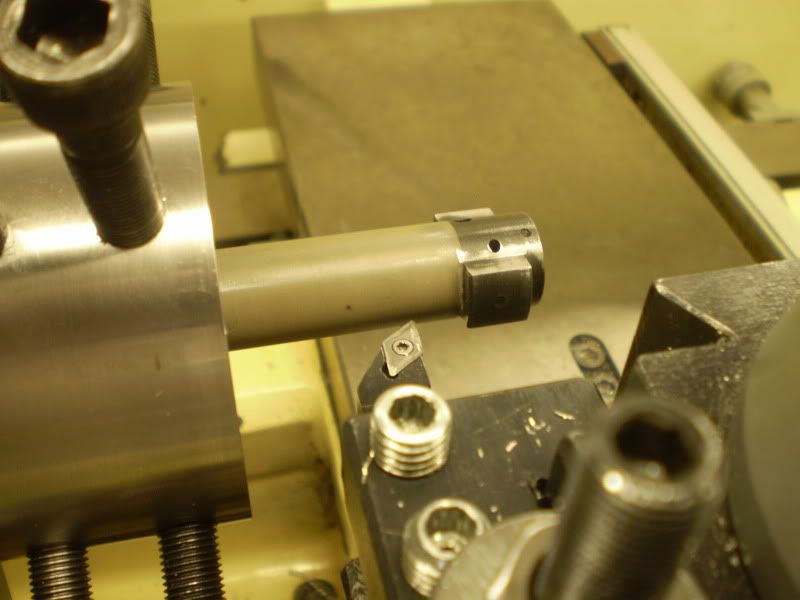

Here is the HOWA set up ready for truing and after cuts were made.

HOWA Bolt ready for truing.

HOWA action/bolt ready for assembly.

Thanks for looking!