I picked up a McMillan HTG M40a1 clone stock. It did not come with pillars from the factory. Should i install pillars or just go shoot it and see how’s it does first? I’ve found very conflicting answers across the web. McMillan says it’s not required but they now install pillars on all new fully inletted stocks as technique but stand by that pillars or bedding are not required unless it’s a edge carbon which this is not. I’m tempting to go shoot it and see how it does?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

Quick Shot Challenge: What’s the most underrated gear you never leave home without?

Contest ends Wednesday, join now for the chance to win free Hide merch!

Join contest

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing Should I install pillars in a McMillan HTG?

- Thread starter Jcaplinger199

- Start date

What's the harm in just giving it a try! If it doesn't perform up to your expectations then have it bedded with pillars.

This was my thought. But figured I’d would post the questionWhat's the harm in just giving it a try! If it doesn't perform up to your expectations then have it bedded with pillars.

These stocks are commonly skim bedded instead of using pillars.

Don't mean to de-rail your thread, but what bottom metal is that stock inlet for? I asked the seller but he wouldn't answer...

Thanks,

DW

Don't mean to de-rail your thread, but what bottom metal is that stock inlet for? I asked the seller but he wouldn't answer...

Thanks,

DW

Ya it took three tries for him to answer. It’s inletted for Remington BDL. I have a Hawkins oberndorf and it dropped right in no problemThese stocks are commonly skim bedded instead of using pillars.

Don't mean to de-rail your thread, but what bottom metal is that stock inlet for? I asked the seller but he wouldn't answer...

Thanks,

DW

Last edited:

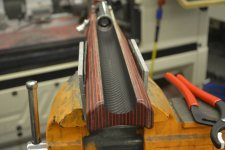

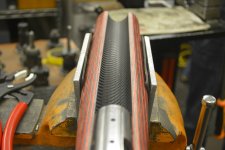

Pillar 101:

When wood ruled the earth for gun stocks, it was discovered that over time the fibers could compress, which resulted in screws loosening up and things going to hell. Then add the whole organic material thing and ambient weather changes. -You have fertile soil for guns that don't want to hold zeros.

The solution was the bedding pillar. Back then, what most used were the little ferrules that hold lampshades on. Cheap and easy.

Aluminum has since taken over the industry. The only "thing" about AL is you really, really have to make sure you scuff the snot out of the OD to ensure that no traces of aluminum oxide are present. (a naturally occurring thing where the outer surfaces develop a skin of AO) The reason is resin doesn't stick to AO for shit. It may look right, but over time it will be more likely to fail.

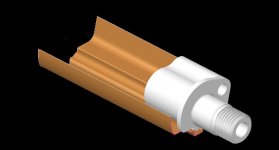

A couple of decades ago, I did some work on an all-carbon stock fitted with AL pillars. In a maritime environment, we learned that didn't go so well. Carbon/AL are polar opposites on the galvanic table, and with an electrolyte (salt water) you just made a battery. So, I make all of my pillars in-house from food/beverage grade stainless. It basically wipes the slate clean on any of the above-mentioned concerns. It also address some other needs that just make our bedding process a little nicer.

As for your HTG: Truth be told, you can probably bolt that thing together and go shoot a decent enough group with it. Skin bedding the stock will help mitigate off-call shots if done correctly. Pillars probably won't make any difference. McMillan core material is plenty tolerant to 50lbs/inch screw torque. If you want blunt honesty, the reason the stock makers and guys like me use pillars is that it's not worth the fight having to explain this ####'s of times a day to people.

The whole point of a composite rifle stock is to avoid the issues that wood brings to the table.

Now you know.

C.

When wood ruled the earth for gun stocks, it was discovered that over time the fibers could compress, which resulted in screws loosening up and things going to hell. Then add the whole organic material thing and ambient weather changes. -You have fertile soil for guns that don't want to hold zeros.

The solution was the bedding pillar. Back then, what most used were the little ferrules that hold lampshades on. Cheap and easy.

Aluminum has since taken over the industry. The only "thing" about AL is you really, really have to make sure you scuff the snot out of the OD to ensure that no traces of aluminum oxide are present. (a naturally occurring thing where the outer surfaces develop a skin of AO) The reason is resin doesn't stick to AO for shit. It may look right, but over time it will be more likely to fail.

A couple of decades ago, I did some work on an all-carbon stock fitted with AL pillars. In a maritime environment, we learned that didn't go so well. Carbon/AL are polar opposites on the galvanic table, and with an electrolyte (salt water) you just made a battery. So, I make all of my pillars in-house from food/beverage grade stainless. It basically wipes the slate clean on any of the above-mentioned concerns. It also address some other needs that just make our bedding process a little nicer.

As for your HTG: Truth be told, you can probably bolt that thing together and go shoot a decent enough group with it. Skin bedding the stock will help mitigate off-call shots if done correctly. Pillars probably won't make any difference. McMillan core material is plenty tolerant to 50lbs/inch screw torque. If you want blunt honesty, the reason the stock makers and guys like me use pillars is that it's not worth the fight having to explain this ####'s of times a day to people.

The whole point of a composite rifle stock is to avoid the issues that wood brings to the table.

Now you know.

C.

Last edited:

As always, Chad's posts not only answer the question at hand but then go above and beyond.

The galvanic corrosion issue is real - bike companies found that out back in the 90s when it first started gluing aluminum to carbon (had an interesting conversation with an engineer during a tour of Trek's Waterloo faculty while I'm college, back when the company actual made stuff in the USA and when I had hair on my head). It's a tough motherfucker to solve. I'm sure the aerospace guys have good answers, but I like Chad's approach better.

Anyways, mark me down for a vote to assemble and shoot the rifle before making big changes. If it were me, I'd probably end up with flyers, blame the stock, bed the thing, and then eventually figure out that the problem was me.

The galvanic corrosion issue is real - bike companies found that out back in the 90s when it first started gluing aluminum to carbon (had an interesting conversation with an engineer during a tour of Trek's Waterloo faculty while I'm college, back when the company actual made stuff in the USA and when I had hair on my head). It's a tough motherfucker to solve. I'm sure the aerospace guys have good answers, but I like Chad's approach better.

Anyways, mark me down for a vote to assemble and shoot the rifle before making big changes. If it were me, I'd probably end up with flyers, blame the stock, bed the thing, and then eventually figure out that the problem was me.

Nice. Wish I could have toured Cannondale’s shop when they were still made in America.As always, Chad's posts not only answer the question at hand but then go above and beyond.

The galvanic corrosion issue is real - bike companies found that out back in the 90s when it first started gluing aluminum to carbon (had an interesting conversation with an engineer during a tour of Trek's Waterloo faculty while I'm college, back when the company actual made stuff in the USA and when I had hair on my head). It's a tough motherfucker to solve. I'm sure the aerospace guys have good answers, but I like Chad's approach better.

Anyways, mark me down for a vote to assemble and shoot the rifle before making big changes. If it were me, I'd probably end up with flyers, blame the stock, bed the thing, and then eventually figure out that the problem was me.

I pillar bed nearly every rifle that I want to shoot well, because everything they make stocks out of ( except metal ) is softer than metal ,so, in time tightening a screw will grind and / or and wear it away bit by bit,maybe ,yes ,way longer than will make a difference,depending on how often it’s screwed and unscrewed, but metal WILL wear less. I prefer brass pillars,stainless steel,steel or aluminum,in that order,I have used them all and brass is easy to work ,use and,make and find.Does it enhance accuracy? Depends on how you look at it,but it assures your stock is fastened the same every time and goes hand in hand with bedding which assures your barrel and stock are aligned perfectly every time you reassemble them,then all you have to do is hold it the same every time and it will shoot the same every time.

Why I love SH.....almost every time an industry expert weighs in, it is immediately followed by someone's "preference" contradicting the expert.....I pillar bed nearly every rifle that I want to shoot well, because everything they make stocks out of ( except metal ) is softer than metal

Should i install pillars or just go shoot it and see how’s it does first?

One test is worth more than a thousand opinions

I pillar bed nearly every rifle that I want to shoot well, because everything they make stocks out of ( except metal ) is softer than metal ,so, in time tightening a screw will grind and / or and wear it away bit by bit,maybe ,yes ,way longer than will make a difference,depending on how often it’s screwed and unscrewed, but metal WILL wear less. I prefer brass pillars,stainless steel,steel or aluminum,in that order,I have used them all and brass is easy to work ,use and,make and find.Does it enhance accuracy? Depends on how you look at it,but it assures your stock is fastened the same every time and goes hand in hand with bedding which assures your barrel and stock are aligned perfectly every time you reassemble them,then all you have to do is hold it the same every time and it will shoot the same every time.

Why should anyone listen to you when you contradict one of the most respected rifle builders in the country?

It's shit-posting such as yours why industry professionals become fewer and fewer every year in firearm forums.

Gale McMillan set a bunch of records with his stocks without pillars. He said they were not required. It should shoot great, you probably will not notice a difference after pillars installed.

Mike

Mike

I pillar bed nearly every rifle that I want to shoot well, because everything they make stocks out of ( except metal ) is softer than metal ,so, in time tightening a screw will grind and / or and wear it away bit by bit,maybe ,yes ,way longer than will make a difference,depending on how often it’s screwed and unscrewed, but metal WILL wear less. I prefer brass pillars,stainless steel,steel or aluminum,in that order,I have used them all and brass is easy to work ,use and,make and find.Does it enhance accuracy? Depends on how you look at it,but it assures your stock is fastened the same every time and goes hand in hand with bedding which assures your barrel and stock are aligned perfectly every time you reassemble them,then all you have to do is hold it the same every time and it will shoot the same every time.

We've skinned this cat several different ways over the years. Brass is nice, but I've yet to see where it offers any advantage over material like 303SS. Especially if you are going to expose it to the nastier things our fair planet offers.

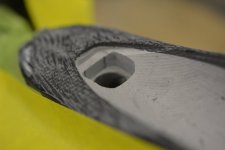

If we're going to take the time to split this hair, then fine. If I was asked, I'm of the opinion that most shops doing this work have it all wrong simply because the inletting is (at best) overlooked and/or (at worst) ignored. Epoxy suffers from a percentage of shrinkage during curing. Its a known consequence of the reaction between the catalyst and the resin. It cannot be avoided. 20+ years ago, I began to inlet my own stocks only because I wanted/needed to know exactly where things were before bedding to accurately predict how thick the film thickness is between receiver/stock. I figured that by doing so, if I made sure it was as even (at least as much as practicality allowed for), then it would at least be uniform from one end to the other. As a bonus, it also makes for really nice-looking work when it's all done.

Now, in a high-performance centerfire action, the gain this offers is so far down in the mud I challenge anyone to find it. Change things up a bit and start dickering with a three-position gun used in ISSF. (Olympic shit) Do this, and things become a whole lot more interesting. This latest trend of building ELR rimfires also plays into this. The Mini Palma game from a decade or more ago does as well.

Why?

The bullet sucks, and it travels at roughly 1/3rd the speed of anything "cool." The cartridge body design is also horrible. You add this all up, and it means that little things start to matter as there is more time for the gun to try and f#ck you over as you shoot it.

Splitting these hairs in this context has shown reward. I'm not talking about over a handful of guns done in a year, either. The volume I've done is well into the #### digit, and it spans decades in a wide variety of disciplines. -Disciplines that offer a controlled environment for meaningful feedback. It takes a 12mm 50 shot group to get on the podium at the Olympics. A 10mm plot will get you gold. Matthew Emmons rifles shot in the low tens to high 9's.

The only other place I've seen this stuff get this picky is in international Palma. The "old" Palma where the 155 grain Sierra was still used. A gun comfortable holding 1/3moa elevation at 1,000 yards from a shoulder-fired 308 Win using iron sights isn't the easiest thing to do. This is most likely because it's just a stupid long barrel to get the required muzzle velocity from such a wimp of a bullet. The sight radius matters too, I suppose.

I suspect that the longer barrel time is the culprit where they kind of emulate the behaviors of a rimfire. As a result, bedding quality and strategy become more relevant. It's a guess because hardly anyone shoots Palma anymore, so it's not like we're building a couple hundred of them a year. We're lucky to see one every couple of years anymore.

Good talk.

C.

Attachments

-

11053927_825478554213571_6636227393745825338_o.jpg200.1 KB · Views: 113

11053927_825478554213571_6636227393745825338_o.jpg200.1 KB · Views: 113 -

11078144_823302691097824_6483373922009055263_o.jpg133.8 KB · Views: 115

11078144_823302691097824_6483373922009055263_o.jpg133.8 KB · Views: 115 -

11119529_822374027857357_7888370265061559805_o.jpg154.8 KB · Views: 113

11119529_822374027857357_7888370265061559805_o.jpg154.8 KB · Views: 113 -

DSC_0021.JPG49.6 KB · Views: 117

DSC_0021.JPG49.6 KB · Views: 117 -

DSC_00104.JPG81.8 KB · Views: 118

DSC_00104.JPG81.8 KB · Views: 118 -

235955795_1853387261507347_6138521447096034397_n.jpg60.8 KB · Views: 110

235955795_1853387261507347_6138521447096034397_n.jpg60.8 KB · Views: 110 -

238247131_1791022527765236_2676103523109315627_n.jpg141.5 KB · Views: 121

238247131_1791022527765236_2676103523109315627_n.jpg141.5 KB · Views: 121 -

240360554_592582248583827_7128711723837297213_n.jpg79.1 KB · Views: 115

240360554_592582248583827_7128711723837297213_n.jpg79.1 KB · Views: 115 -

20190822_093413.jpg560.2 KB · Views: 105

20190822_093413.jpg560.2 KB · Views: 105 -

16179067_660354674143951_7076646678662989056_o.jpg173.9 KB · Views: 96

16179067_660354674143951_7076646678662989056_o.jpg173.9 KB · Views: 96 -

16177652_660337590812326_8764126145770163421_o.jpg253.2 KB · Views: 98

16177652_660337590812326_8764126145770163421_o.jpg253.2 KB · Views: 98 -

16143868_660337780812307_6376202591124130476_o.jpg24.4 KB · Views: 93

16143868_660337780812307_6376202591124130476_o.jpg24.4 KB · Views: 93 -

10872937_764881323606628_5082150487019548340_o.jpg93.1 KB · Views: 92

10872937_764881323606628_5082150487019548340_o.jpg93.1 KB · Views: 92 -

20170719_144619.jpg348 KB · Views: 101

20170719_144619.jpg348 KB · Views: 101 -

20170822_190333.jpg390.6 KB · Views: 106

20170822_190333.jpg390.6 KB · Views: 106 -

DSC_0060.jpg40.7 KB · Views: 128

DSC_0060.jpg40.7 KB · Views: 128 -

16112530_660337930812292_6218534492279723077_o.jpg272.7 KB · Views: 103

16112530_660337930812292_6218534492279723077_o.jpg272.7 KB · Views: 103 -

16113137_660338344145584_7814816879787677810_o.jpg272.4 KB · Views: 92

16113137_660338344145584_7814816879787677810_o.jpg272.4 KB · Views: 92 -

16143551_660337834145635_8666519774435744330_o.jpg265.6 KB · Views: 103

16143551_660337834145635_8666519774435744330_o.jpg265.6 KB · Views: 103 -

16143629_660354540810631_3949721216964924796_o.jpg189.2 KB · Views: 98

16143629_660354540810631_3949721216964924796_o.jpg189.2 KB · Views: 98 -

16143792_660354477477304_2315372971367790154_o.jpg192.9 KB · Views: 96

16143792_660354477477304_2315372971367790154_o.jpg192.9 KB · Views: 96 -

20190822_093635.jpg619.9 KB · Views: 139

20190822_093635.jpg619.9 KB · Views: 139

Last edited:

Similar threads

- Replies

- 2

- Views

- 503