Now what do I do with this info?

I was curious as to the length of my .308 Savage's chamber. And rather than buy a tool, I made one.

I took a piece of fire formed brass and neck sized it just enough to hold a bullet. Kinda the same way that you would in order to find the lands. I then cut the neck in half and chamfered/cleaned up the pieces. Finally, I seated a bullet (168gr Hornady) and just rested the piece of neck brass around the bullet as pictured below.

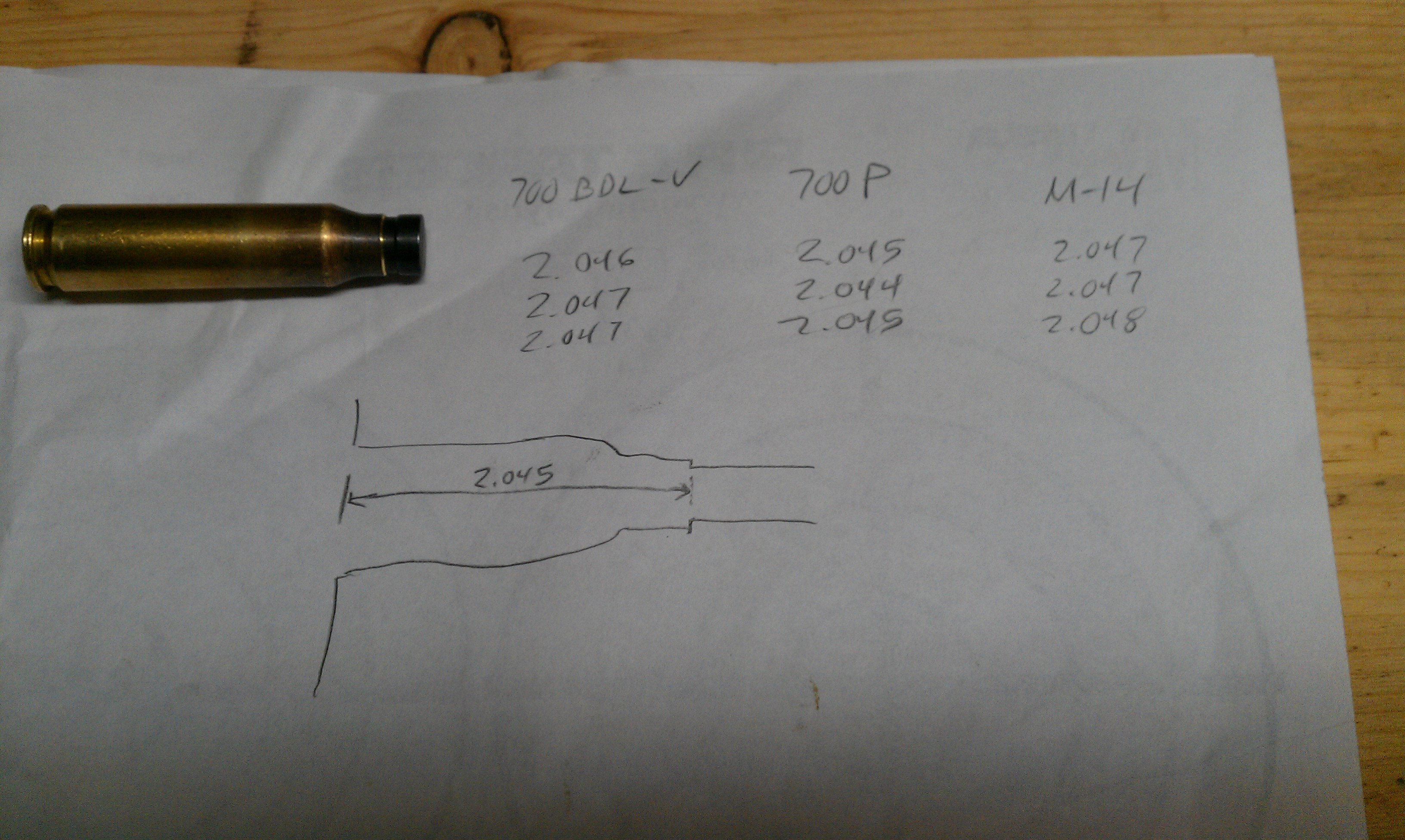

Shoved it in the chamber and got this.

I measured the brass length and it came to 2.035. Repeated process a few times to confirm.

Does this number sound correct? And what should I do with it? My virgin Winchester brass measures around 2.007. Should I just let the brass grow and keep it trimmed to 2.025, .010 under? I would like to have as much brass as possible to hold the bullet.

I was curious as to the length of my .308 Savage's chamber. And rather than buy a tool, I made one.

I took a piece of fire formed brass and neck sized it just enough to hold a bullet. Kinda the same way that you would in order to find the lands. I then cut the neck in half and chamfered/cleaned up the pieces. Finally, I seated a bullet (168gr Hornady) and just rested the piece of neck brass around the bullet as pictured below.

Shoved it in the chamber and got this.

I measured the brass length and it came to 2.035. Repeated process a few times to confirm.

Does this number sound correct? And what should I do with it? My virgin Winchester brass measures around 2.007. Should I just let the brass grow and keep it trimmed to 2.025, .010 under? I would like to have as much brass as possible to hold the bullet.