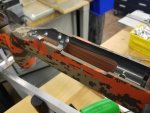

New machine on the floor Wednesday. Serviced/setup on Thursday. 5x new computer towers for ALL the machines delivered from New Egg on Friday afternoon. Saturday was a "geek orgy" putting them all together.

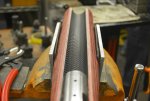

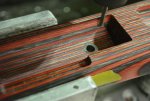

Monday, were making chips. Our new machine is a late 90's vintage 4 axis VF2. Sole purpose is stock work. Were fixtured up and running right now. New subplates and a new fixture to take advantage of the 4th axis is on its way from Minneapolis. HARDOX 400 plate that's been stress relieved and ground. Soon as it gets here (big sum buggers) we'll be ready to really kick this arse.

Sooo much nicer now that Tanner and I aren't fighting for spindle time on the machines.

Growth is awesome! Thank you again.

C.

New "NORAD" system for doodling programs.

[IMG2=JSON]{"alt":"Image may contain: screen, office, table and indoor","data-align":"none","data-size":"full","src":"https:\/\/scontent-ord1-1.xx.fbcdn.net\/v\/t1.0-9\/17884340_1310684002359688_5167540892749559110_n.jpg?oh=145410e82363460fd0483bffe501246d&oe=5987FD52"}[/IMG2]

Monday, were making chips. Our new machine is a late 90's vintage 4 axis VF2. Sole purpose is stock work. Were fixtured up and running right now. New subplates and a new fixture to take advantage of the 4th axis is on its way from Minneapolis. HARDOX 400 plate that's been stress relieved and ground. Soon as it gets here (big sum buggers) we'll be ready to really kick this arse.

Sooo much nicer now that Tanner and I aren't fighting for spindle time on the machines.

Growth is awesome! Thank you again.

C.

New "NORAD" system for doodling programs.

[IMG2=JSON]{"alt":"Image may contain: screen, office, table and indoor","data-align":"none","data-size":"full","src":"https:\/\/scontent-ord1-1.xx.fbcdn.net\/v\/t1.0-9\/17884340_1310684002359688_5167540892749559110_n.jpg?oh=145410e82363460fd0483bffe501246d&oe=5987FD52"}[/IMG2]