Re: thread for home made gun smithing jigs

Sure had to dig for this thread as it was buried quite a ways back. But I found it so I thought I’d put up a few of my latest projects that I’ve completed.

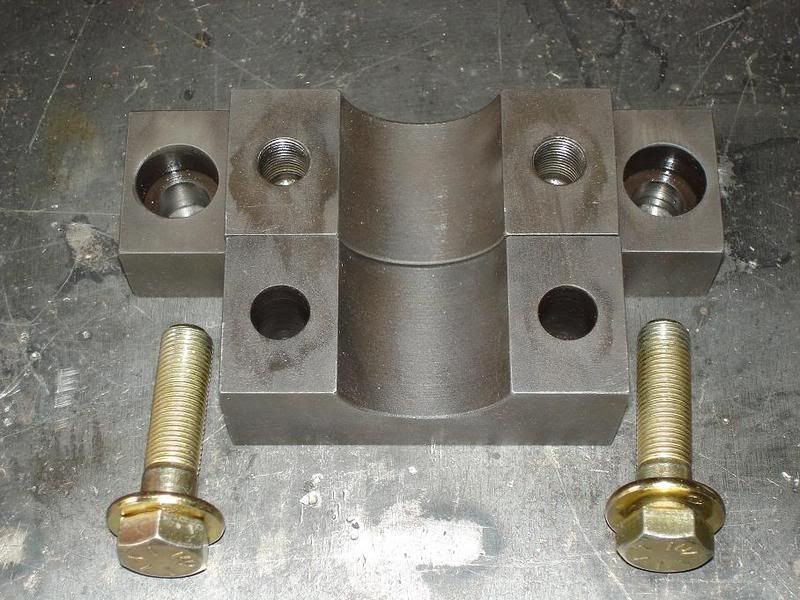

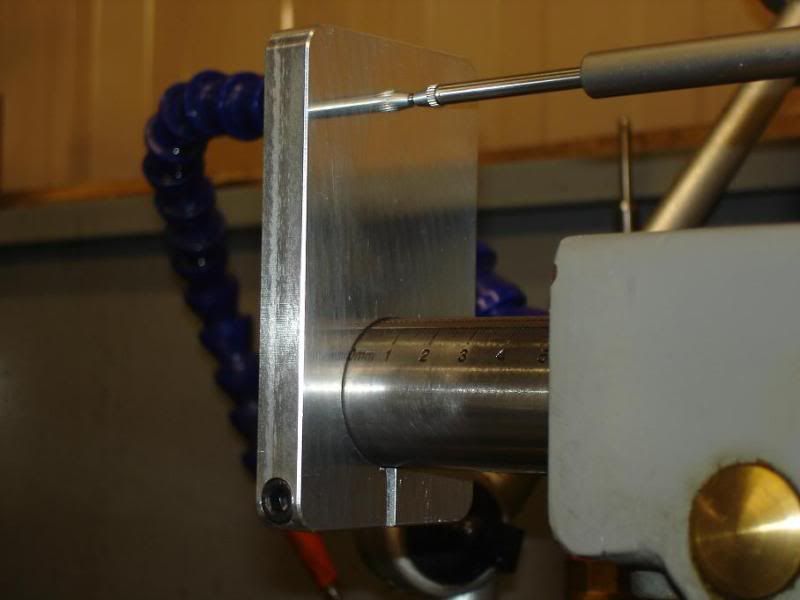

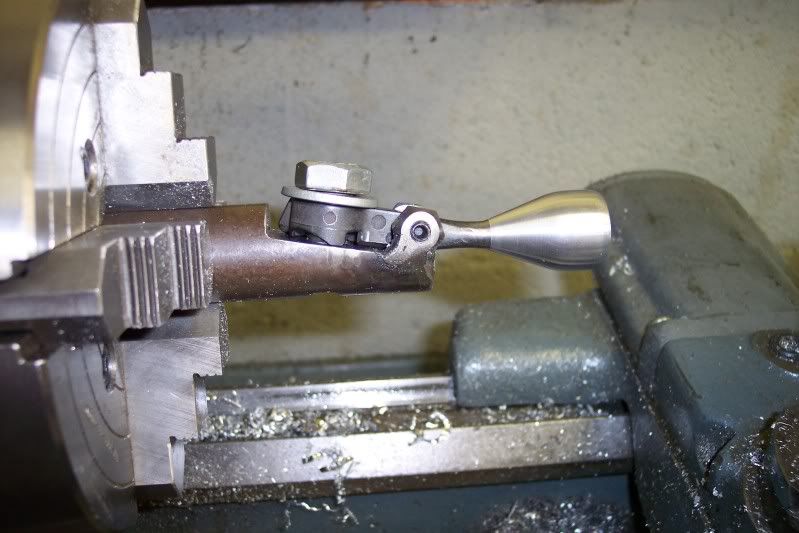

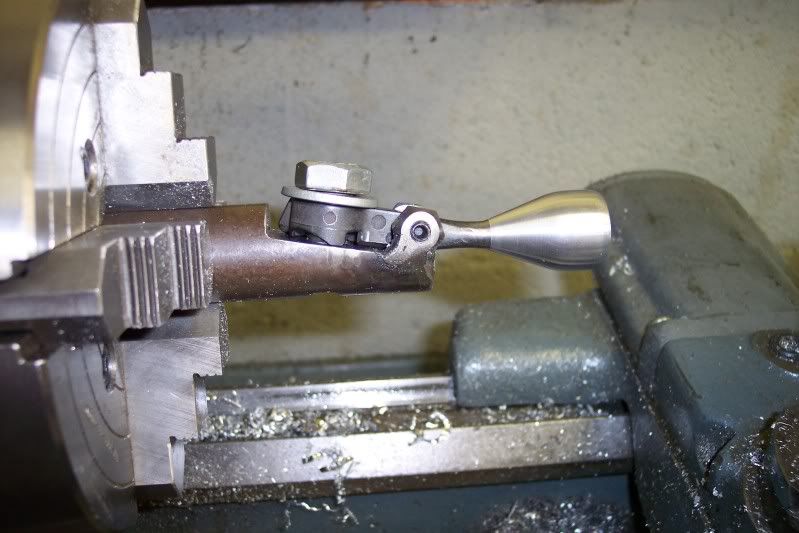

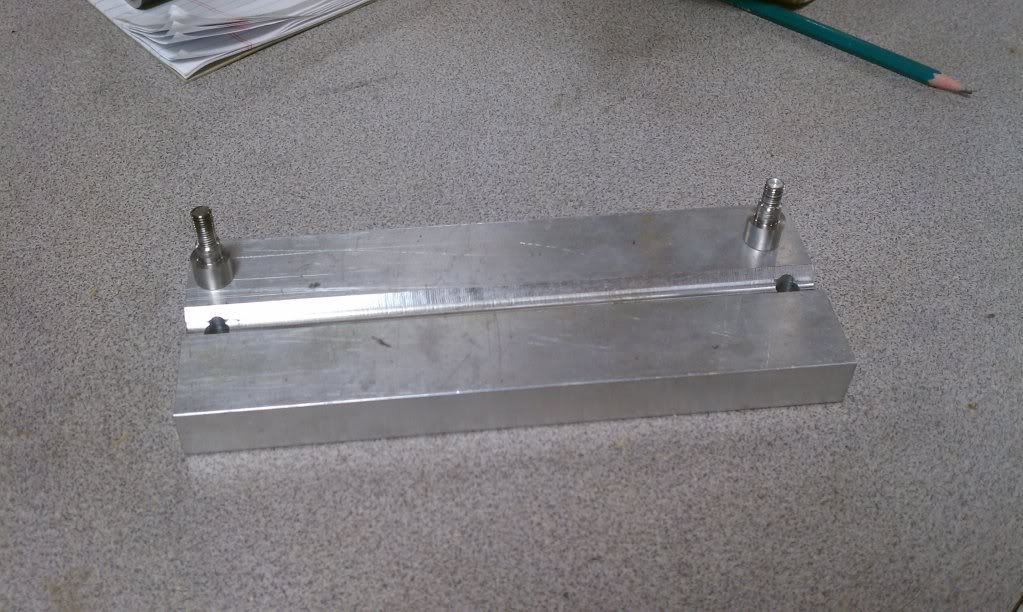

Borrowing 300sniper’s idea, I made a jig for installing bolt handles. This began life as a 4”x4” block of hot-rolled so it took quite a bit of milling to get it to this stage. The slot that holds the shaft of the factory knob is tapered on the sides so the shaft fits securely in the jig with zero clearance. The cover plate is attached with 3/8 x 24 bolts and has a tab that corresponds with the slot to allow a secure hold on the bolt’s shaft. Looks like I need to widen that slot a tad as this bolt handle sits lower than others that I have done. Must be some variation in Remington’s handles.

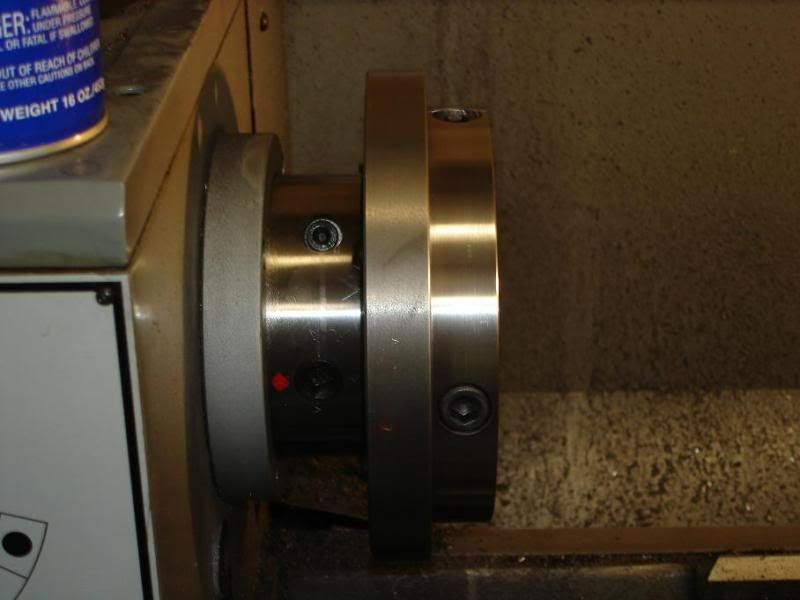

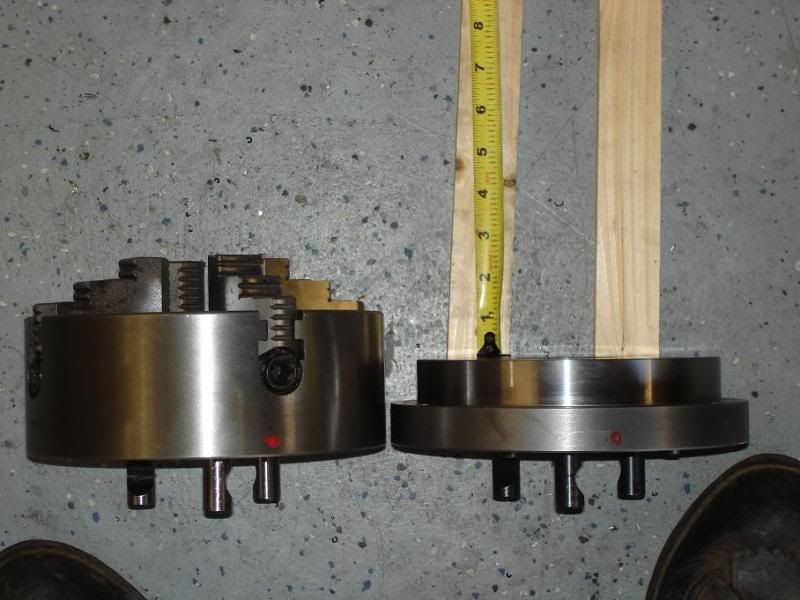

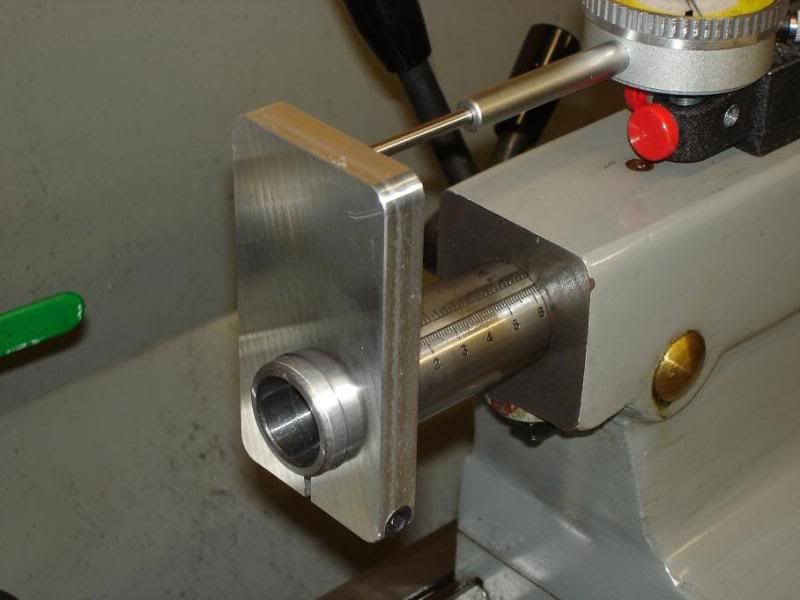

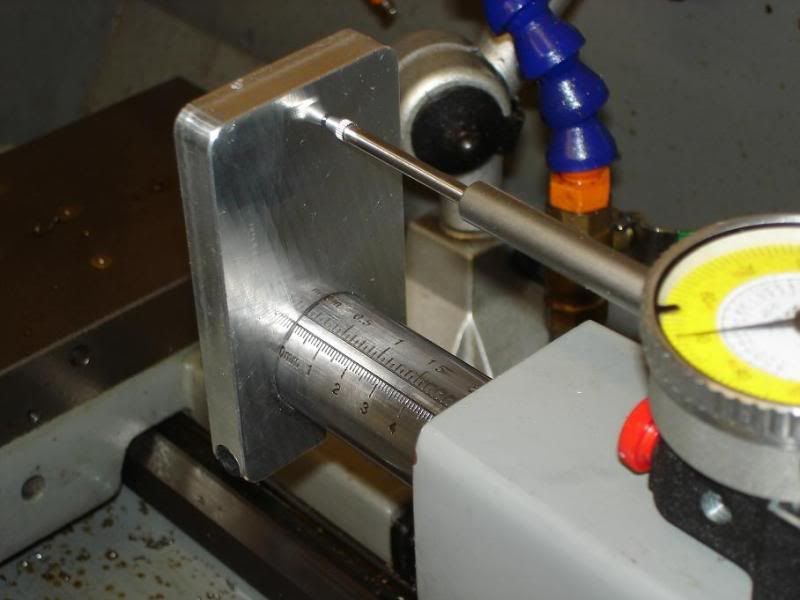

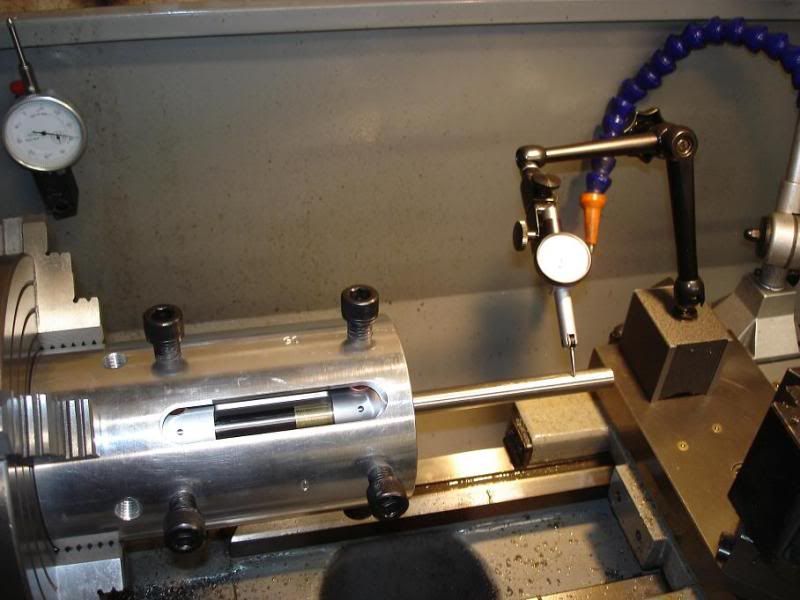

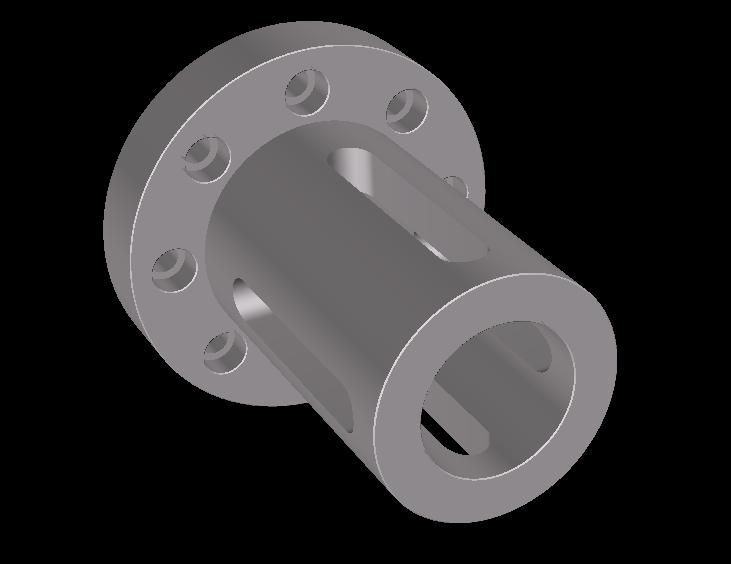

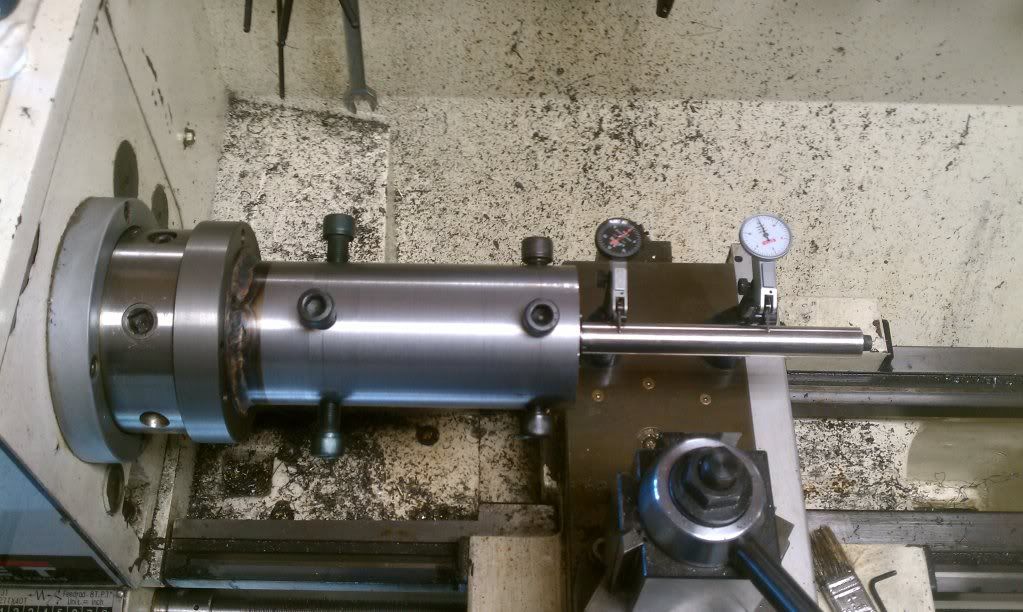

I also finally completed my receiver blueprinting jig for the lathe. The jig was made from 4.25” round aluminum which meant a lot of machine time getting to the final dimensions. I didn’t really want to have to use it in a 4-jaw chuck so I bought a blank backplate from Grizzly, faced it off, machined the OD down, and then inletted it for the jig. The jig installed with a slight press fit and 6 bolts secure it. I was worried for a while as the ID of the plate was quite a bit larger than the ID of the jig. Turns out that I had just enough width to get some 5/16 x 24 bolts in there. It’s not going anywhere.

Whipped up a set of shorter ½ x 20 brass-tipped bolts for the jig. Also made a false center for Remington bolts.

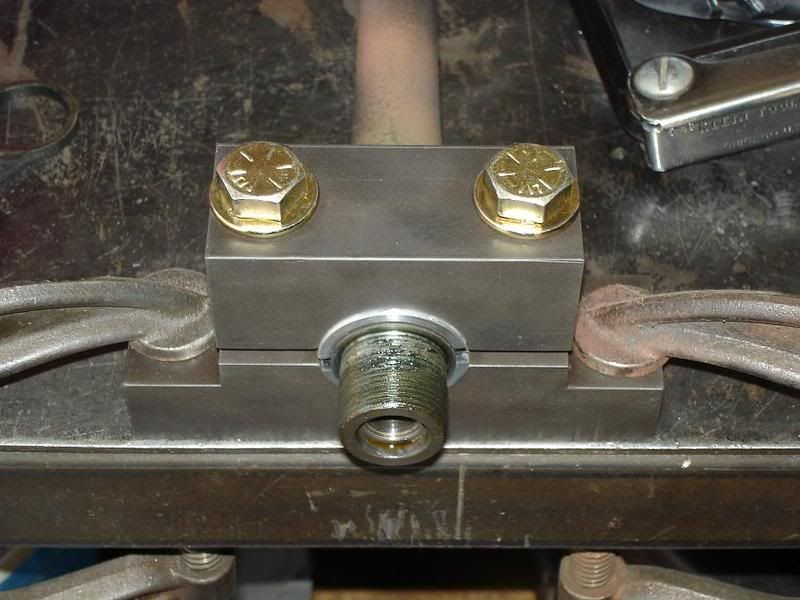

Made a barrel vise similar to the one that Brownell’s sells. The brass bushing is made for standard Remington barrels. If I need any more bushings they will be made out of aluminum as it’s easier to work with, less expensive, and works just as well for the application.

All of this was done using a Lathemaster ZAY45 mill and a Grizzly G4003G lathe. Both of these machines do nice work but I definitely need a larger beefier mill. 2012 will see a 10 x 54 knee mill of some pedigree for sure.