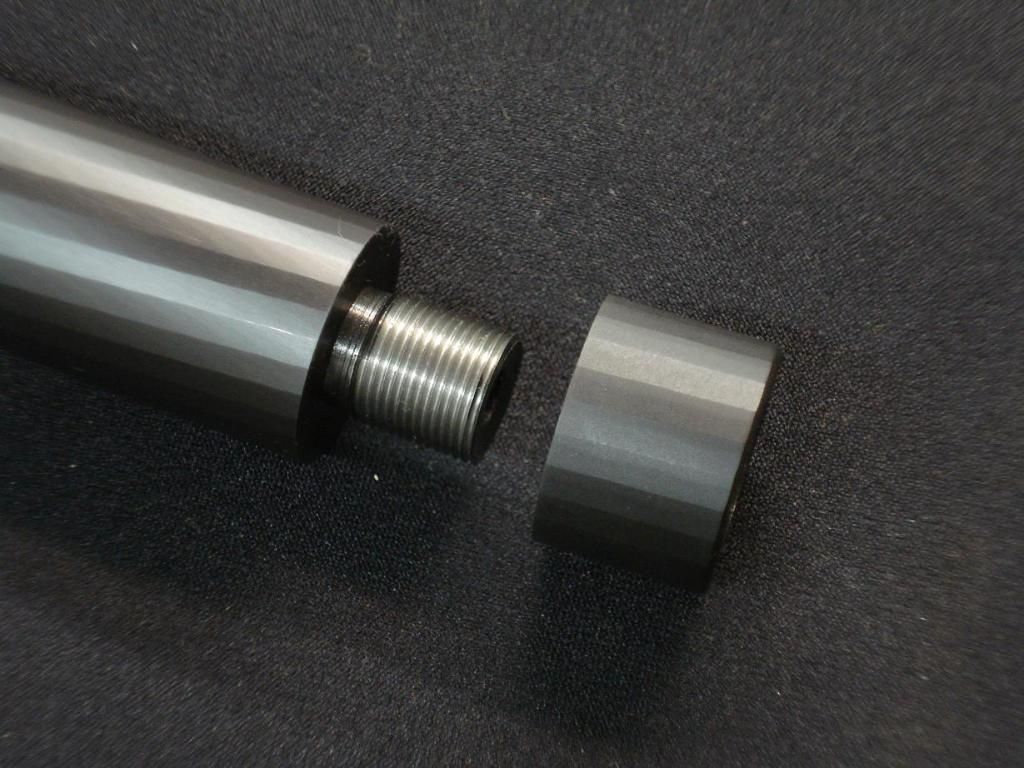

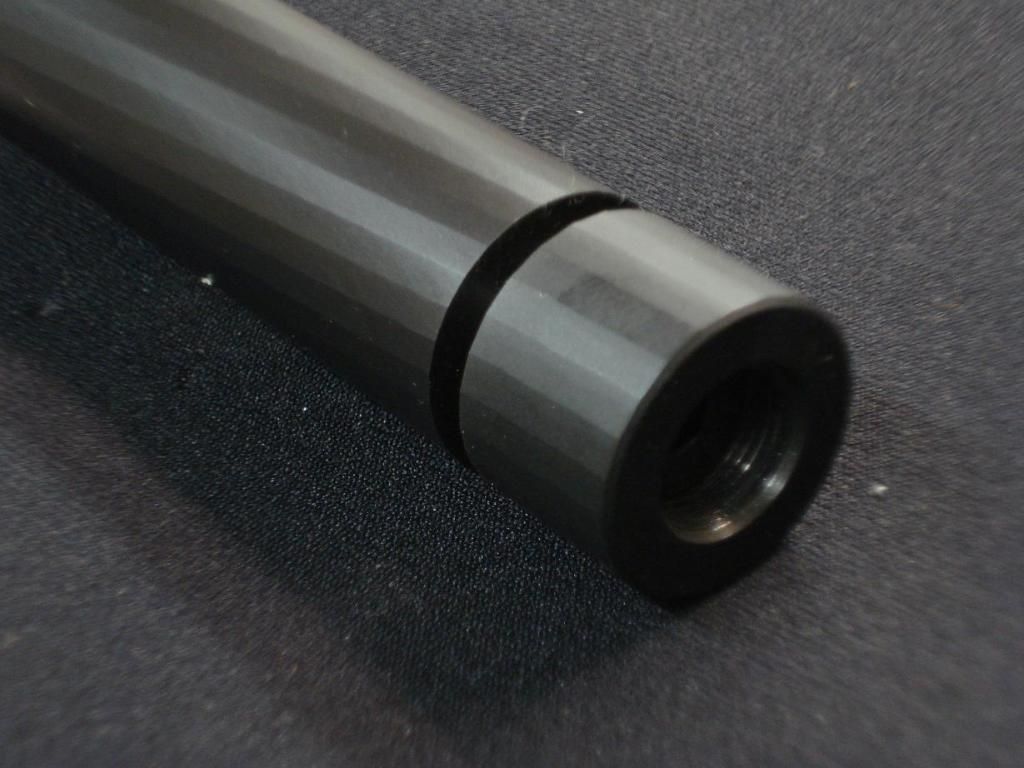

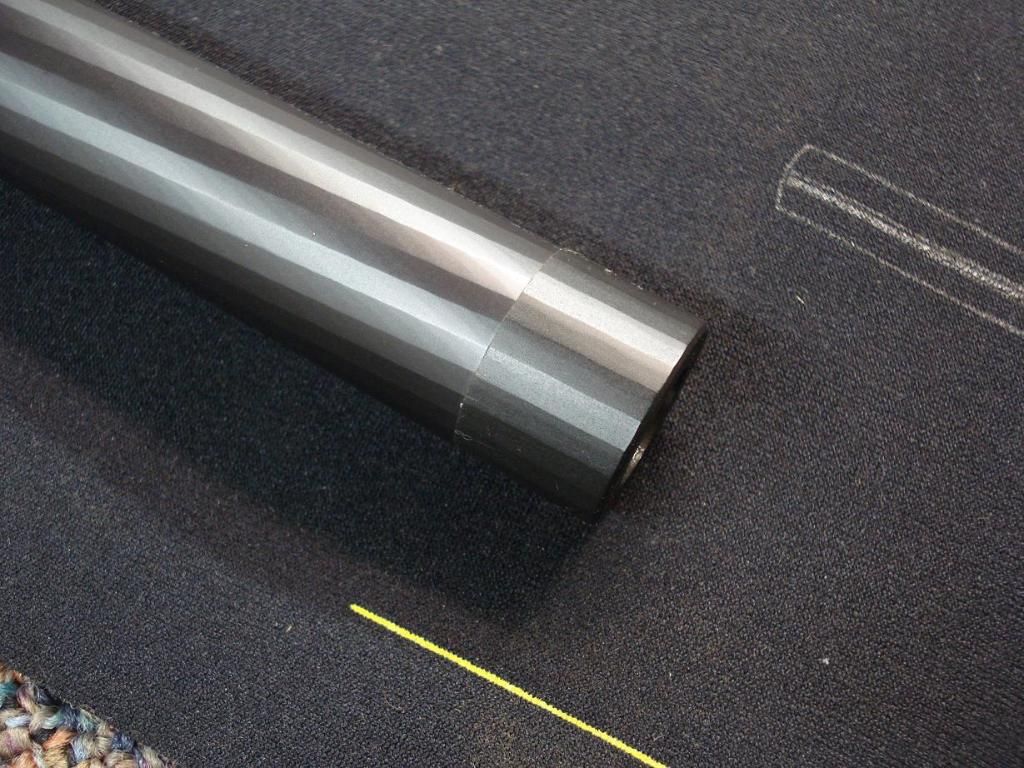

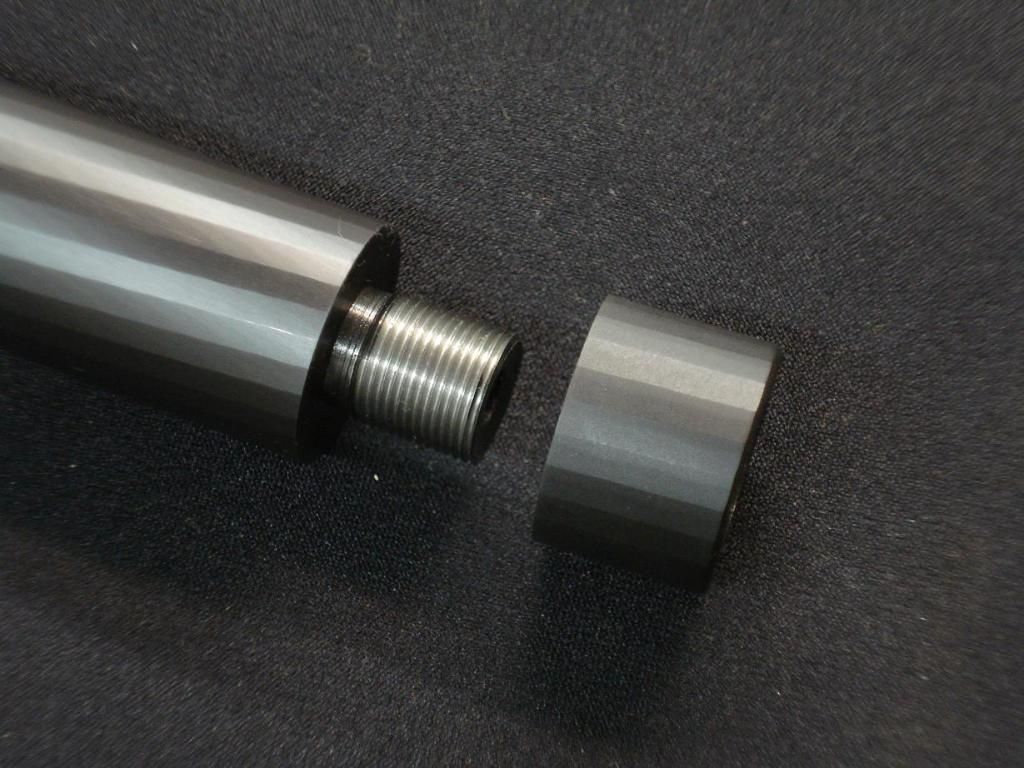

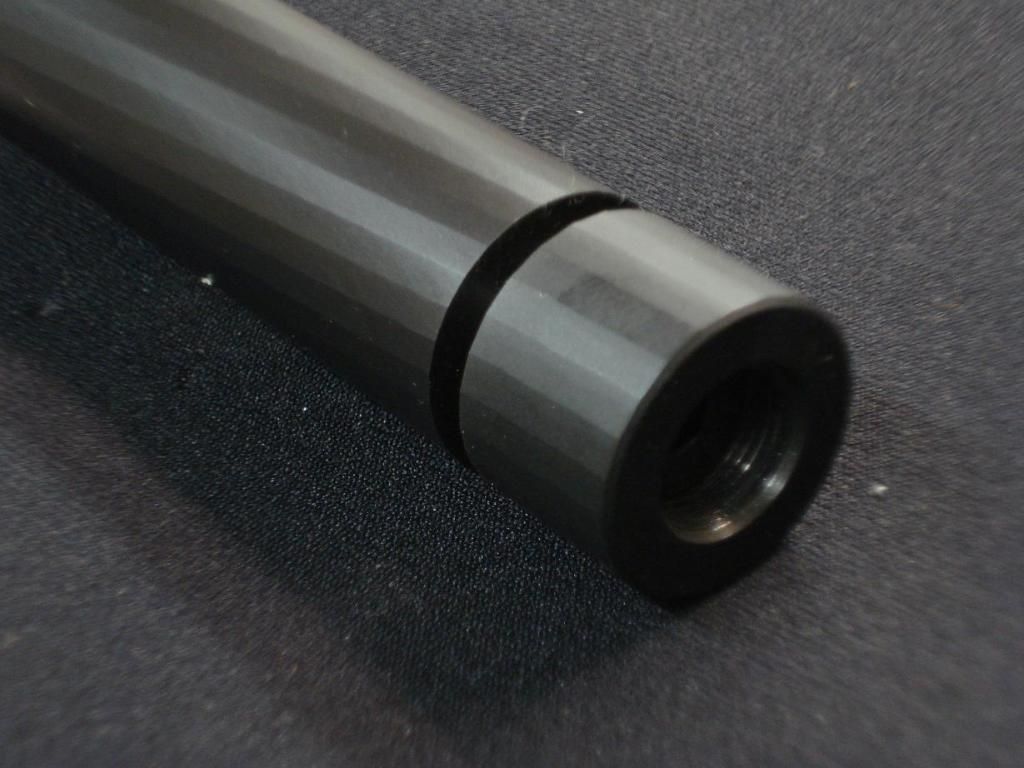

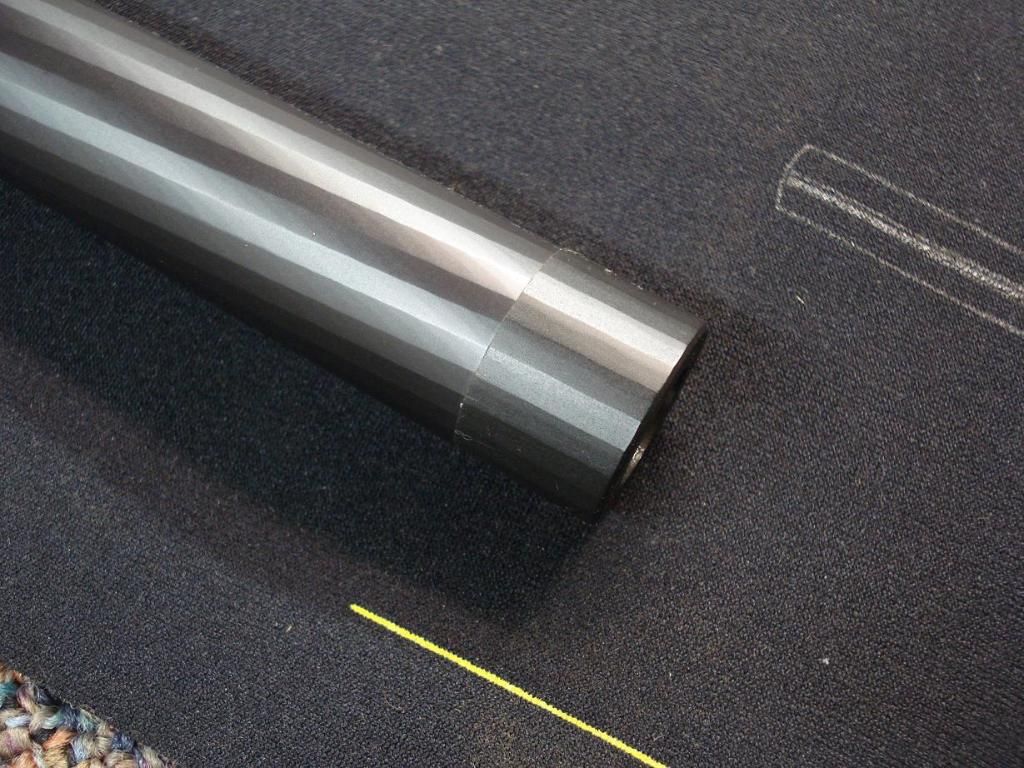

Hey Gents, I needed to make a thread protector for a customers Ruger 10/22 with a spiral fluted barrel. I just happened to own the same Ruger 10/22 but mine had a blued spiral fluted barrel, customers was black.

Anyway, I could not think of a way of making a thread protector that would look good. Possibly knurling, but I figured this would work out just fine. Since my barrel is not his barrel, the fluted did not match up like I hoped they would have, but I think it still looks ok. Every time I tried to time the flutes, one side would match up very well, then the other was off. I KG Gunkoted the thread protector because it matches the Ruger Factory black pretty close.

Anyway, I could not think of a way of making a thread protector that would look good. Possibly knurling, but I figured this would work out just fine. Since my barrel is not his barrel, the fluted did not match up like I hoped they would have, but I think it still looks ok. Every time I tried to time the flutes, one side would match up very well, then the other was off. I KG Gunkoted the thread protector because it matches the Ruger Factory black pretty close.