Tried to remove the slot head screws on the picatinny rail with a screwdriver and ratchet with bit, but they just slip out of the slot because the screws are really stuck. What is the deal, glue? And how can I get them out safely?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing Tikka T3 rail slot headed screws stuck, how to get them out without stripping?

- Thread starter razzle

- Start date

Shouldn't be glued, though I have heard some of the rails were epoxied into place (never seen it first hand on the two I have; Varmint & CTR).

Do you have a manual impact driver? That usually helps get stuck screws loose without beating them up too badly. Applying some Kroils also helps (just don't get that stuff anywhere near your scope rings).

https://www.zoro.com/proto-driver-h...hoTzv-G1Pxa7T7Wdk6oaAnNREALw_wcB&gclsrc=aw.ds

BTW, I asked the question because the Varmint had plastic threaded plugs that looked like screws, but it sounds like you just have some stuck screws.

Do you have a manual impact driver? That usually helps get stuck screws loose without beating them up too badly. Applying some Kroils also helps (just don't get that stuff anywhere near your scope rings).

https://www.zoro.com/proto-driver-h...hoTzv-G1Pxa7T7Wdk6oaAnNREALw_wcB&gclsrc=aw.ds

BTW, I asked the question because the Varmint had plastic threaded plugs that looked like screws, but it sounds like you just have some stuck screws.

Last edited:

Getting the Rail off my CTR was a pain in the ass. Almost stripped all of the screws. I did not use heat, which was my mistake initially. I applied heat half way through and i was just barely able to get the screws out without stipping them all. I had to use an Extractor Set on one of the screws.

So, use heat before messing with screws. They have loctite on them and need the heat to loosen. The picatinny rail was epoxied to the action, again, heat helped remove the rail.

Good news is I learned alot, bad news is, I'm getting ready to remove another one. GOOD LUCK! Heat and Patience!

So, use heat before messing with screws. They have loctite on them and need the heat to loosen. The picatinny rail was epoxied to the action, again, heat helped remove the rail.

Good news is I learned alot, bad news is, I'm getting ready to remove another one. GOOD LUCK! Heat and Patience!

Tried with a heatgun on one of the screws for a while and gave it another try, but I ended up stripping it

Not sure this actually is Loctite as it is clear, both on the rail and the screws. Wouldn't be surprised if they applied epoxy to both the rail and the screws. So I gave up, will drop off the rifle at the local gunsmith today and will get it back tomorrow. Who uses slotted screws in the 21st century??

Not sure this actually is Loctite as it is clear, both on the rail and the screws. Wouldn't be surprised if they applied epoxy to both the rail and the screws. So I gave up, will drop off the rifle at the local gunsmith today and will get it back tomorrow. Who uses slotted screws in the 21st century??

Mine was a PITA, too! Same issue, stripped them out. Heat gun helped with the epoxy.

Tikka really needs to start shipping these with 20moa rails.

Tikka really needs to start shipping these with 20moa rails.

EGW says to run a 6-48 tap into the holes if you're having problems getting their supplied screws to start - that's if your rifle was made after 2004; ones prior to then had metric threads for the scope rail. They say that it's common for the plastic plugs to leave some material behind in the threads when they're removed, and a proper size tap will easily remove it. My problem is in getting the factory plastic plugs out of the holes so I can mount the EGW 20 MOA rail on a brand new T3x Lite that I just ordered in from Lipsey's last week. FedEx delivered several scope rails I'd ordered from EGW late last evening, so I was trying to back those sorry plastic plugs out, and not one of them will unscrew out far enough to be removed. About ready to pull the bbl'd action out of the stock and put it in the vise on my vertical mill so I can drill the sorry little SOBs out...

OG10 - I was in a hurry to attach an EGW 20 MOA sloped rail on the new 223 T3x this morning; was wanting to get a 6-24x50 Midas TAC mounted so I could zero it this evening, and was needing to get out of the shop & onto the sprayer. So didn't get a flashlight to look at the underside of the rear receiver ring to see if the tapped holes went clear through. But that's a whole lot safer way to deal with these wimpy plastic plugs than trying to drill them out. Kind of an odd thing to do at the factory, especially since the machine work & finish on the metal parts of this T3x Lite are impressive. Next time I have time to work on it, I'll get the Starrett punch set & a 6-48 tap out and deal with the plastic plugs. Thanks for the suggestion.@flaland1 if you do indeed have the plastic plugs t3, t3x just use a small punch and drive the plugs into the receiver.This works well with the plastic plugs, the run the appropriate tap and clean the threads.Any questions let me know.

An impact driver (the kind you tap with a hammer and slowly rotate) can work wonders on overly tight screws. A bit of heat will help to soften the epoxy if it is stuck in the threads too.

Make sure you are using a correctly sized hollow ground gun smiths screwdriver for starters. You can really crank on a flathead if you have the correct size for the job. Most of the time when I see buggered up screws it's because someone went at it with a standard screwdriver

ThisMake sure you are using a correctly sized hollow ground gun smiths screwdriver for starters. You can really crank on a flathead if you have the correct size for the job. Most of the time when I see buggered up screws it's because someone went at it with a standard screwdriver

Parallel sides on the gunsmith bits make a huge difference

Assuming the screws are metal (I am a little lost with the talk of plastic plugs?) and there's no other super fragile substrate (plastic or wood rails, frame) then the best way to get heat into a small area like a screw is a soldering iron. Even a tiny one (as small as 15w) will heat up the screw, thus any threadlocker or gummed up assembly grease, improperly applied WD40, etc. and should give you a minute to get it out. Let the iron get full heat, use a pointy tip, and just place it right on the head for 10-15 seconds.

Also make sure the workpiece is well secured, and make sure you have a hollow ground driver of the right size. You want as little movement between the bit and screw head as possible, and as much width as possible without going outside it and buggering up what is beyond it.

Also make sure the workpiece is well secured, and make sure you have a hollow ground driver of the right size. You want as little movement between the bit and screw head as possible, and as much width as possible without going outside it and buggering up what is beyond it.

My brand new Tikka T3x Lite (got it last week from Lipsey's) came with black plastic plugs in the scope base tapped holes. Maybe older rifles came with steel plugs, but I'm here to tell you, the newest rifles come with these plastic plugs. Using a hollow ground screwdriver has nothing to do with getting them out - the plastic threads aren't strong enough to last long enough to allow me to back them out - and it's not the screwdriver slot that fails, it's the plug threads themselves. I simply got a pin punch & light machinist's hammer and drove them down into the action until they fell out. It took only a few light taps on the punch to drive them through the receiver rings. Afterwards, I set the rail in place, put a dab of #242 blue loctite on each screw, and tightened them. It's sitting in the safe overnight, and should be ready to mount a scope & zero tomorrow or Sunday.

Last edited:

me 2Mine was a PITA, too! Same issue, stripped them out. Heat gun helped with the epoxy.

Tikka really needs to start shipping these with 20moa rails.

If your tikka came from the factory with a rail, ctr varmit it has metal screws.If your tikka came witha dovetail /flat top receiver aka t3 lite, t3x lite or superlight either t3 or t3x it will have plastic screws/ plugg in the top.This should clear up the plastic vs steel issue.

The T3x Lite I bought is my first Tikka. Have been reading so many positive reviews over the past few years that I'd been thinking about buying one of these rifles to find out what all the hub-bub is about for some time. A couple of months ago, while at B&C to pick out a stock for a Howa Mini, Brandon showed me a T3x CTR that they use to check the fitting of inlets. I was flat amazed at how slick the CTR's bolt ran, and it was handling this rifle that convinced me to buy a T3x. I picked the least expensive model in 223, thinking it'd make a great truck gun.

The one thing I don't care for on this rifle is the magazine - pretty short for any of the loads with longer bullets that the 1-8tw bbl would handle well, and only 4rd capacity. That'd be no sweat if there were reasonably priced 10rd mags with room for longer rounds available somewhere. I've done some searching, but haven't seen anything yet. What am I missing?

The one thing I don't care for on this rifle is the magazine - pretty short for any of the loads with longer bullets that the 1-8tw bbl would handle well, and only 4rd capacity. That'd be no sweat if there were reasonably priced 10rd mags with room for longer rounds available somewhere. I've done some searching, but haven't seen anything yet. What am I missing?

That you’re trying to do non lite stuff with a lite purposed rifle. Put it in a chassis or stock with some bottom metal and run the aics mags.The one thing I don't care for on this rifle is the magazine - pretty short for any of the loads with longer bullets that the 1-8tw bbl would handle well, and only 4rd capacity. That'd be no sweat if there were reasonably priced 10rd mags with room for longer rounds available somewhere. I've done some searching, but haven't seen anything yet. What am I missing?

The one thing I don't care for on this rifle is the magazine - pretty short for any of the loads with longer bullets that the 1-8tw bbl would handle well, and only 4rd capacity. That'd be no sweat if there were reasonably priced 10rd mags with room for longer rounds available somewhere. I've done some searching, but haven't seen anything yet. What am I missing?

Depending on how handy you are I am almost positive the rear block is removeable/modifiable to allow a longer coal. You might need to do a bit of work to the follower as well though depending on how long you really want to go.

Hello from France

I have just removed the standard Tikka 0 MOA rail from my Tikka T3X CTR.

I have heated precisely the tip of one screw with a standard Iron Tip to soften the epoxy, then remove the screw. (Repeat 5 times)

Then the rail came gently , there wasn’t a lot of epoxy as you can see, they applied a layer of epoxy on top of chassis, but not directly on each screw.

The perfect tool would be a Torx Tip soldered to the Iron tip in order to turn while heating

I was a little worried by the disassembly !!

I have just removed the standard Tikka 0 MOA rail from my Tikka T3X CTR.

I have heated precisely the tip of one screw with a standard Iron Tip to soften the epoxy, then remove the screw. (Repeat 5 times)

Then the rail came gently , there wasn’t a lot of epoxy as you can see, they applied a layer of epoxy on top of chassis, but not directly on each screw.

The perfect tool would be a Torx Tip soldered to the Iron tip in order to turn while heating

I was a little worried by the disassembly !!

Last edited:

How I've done this for a couple of decades now:

Assuming you have the correct screwdrivers for this kind of thing. The blade portion needs to fit with a mild interference into the slot of the screw. Enough to where a few tappy taps with a whakkah gets it seated properly to the root of the slot.

From there I'll just give it the ol Lefty Loosey and see how much it puts up a fuss. If it cusses back at me, it's time for FUEGO. One of those Butane crack torches. I'll pull the driver and leave the tool in the screw and heat up the top portion of the insert and allow the heat to travel down to the screw and wander its way into the threads. Once I get the whiff of sweet-smelling Lok Tite I know it's starting to work.

I'll let it sit for a minute to ensure it is heat soaked and from there it's typically very easy to remove as the screw head will expand slightly and reduce the preload. There's one part of this to also pay attention to. New guys here at the shop suffer from this until they listen and learn how to actually use these tools.

A flat blade screw goes to great lengths to try and F%$# you every chance it gets. Quite often its the operator as he/she is turning the thing. A wrist gets kinked, the tool goes off axis, and the blade tears the snot out of the screw slot. The practice I've adopted is to grip the driver with my thumb pointing up. The rifle is on the bench with the screw presenting vertically. I tuck that screwdriver close to my chest with my arm more or less "chicken winged". I seat the insert into the head, attach the driver, and with all the downward pressure I can muster, I'll start to turn the thing in the LL direction. The idea is to reduce moments wherever possible so that the tool doesn't get cockeyed and tear stuff up. Trying to describe this likely makes me sound like a bigger moron than usual, but hopefully, it's articulated well enough.

-Side note. It's AWESOMELY, Hysterically, entertaining to do this in front of Palma shooters on the screw that positions the scale on a Warner Palma sight. All your doing is ensuring you are not tearing the head of the screw but they assume you are trying to tighten it as if your hand is a 1/2" impact gun.

The cardiac response they have never fails to disappoint. Lol.

Hope this helps.

C.

Assuming you have the correct screwdrivers for this kind of thing. The blade portion needs to fit with a mild interference into the slot of the screw. Enough to where a few tappy taps with a whakkah gets it seated properly to the root of the slot.

From there I'll just give it the ol Lefty Loosey and see how much it puts up a fuss. If it cusses back at me, it's time for FUEGO. One of those Butane crack torches. I'll pull the driver and leave the tool in the screw and heat up the top portion of the insert and allow the heat to travel down to the screw and wander its way into the threads. Once I get the whiff of sweet-smelling Lok Tite I know it's starting to work.

I'll let it sit for a minute to ensure it is heat soaked and from there it's typically very easy to remove as the screw head will expand slightly and reduce the preload. There's one part of this to also pay attention to. New guys here at the shop suffer from this until they listen and learn how to actually use these tools.

A flat blade screw goes to great lengths to try and F%$# you every chance it gets. Quite often its the operator as he/she is turning the thing. A wrist gets kinked, the tool goes off axis, and the blade tears the snot out of the screw slot. The practice I've adopted is to grip the driver with my thumb pointing up. The rifle is on the bench with the screw presenting vertically. I tuck that screwdriver close to my chest with my arm more or less "chicken winged". I seat the insert into the head, attach the driver, and with all the downward pressure I can muster, I'll start to turn the thing in the LL direction. The idea is to reduce moments wherever possible so that the tool doesn't get cockeyed and tear stuff up. Trying to describe this likely makes me sound like a bigger moron than usual, but hopefully, it's articulated well enough.

-Side note. It's AWESOMELY, Hysterically, entertaining to do this in front of Palma shooters on the screw that positions the scale on a Warner Palma sight. All your doing is ensuring you are not tearing the head of the screw but they assume you are trying to tighten it as if your hand is a 1/2" impact gun.

The cardiac response they have never fails to disappoint. Lol.

Hope this helps.

C.

Last edited:

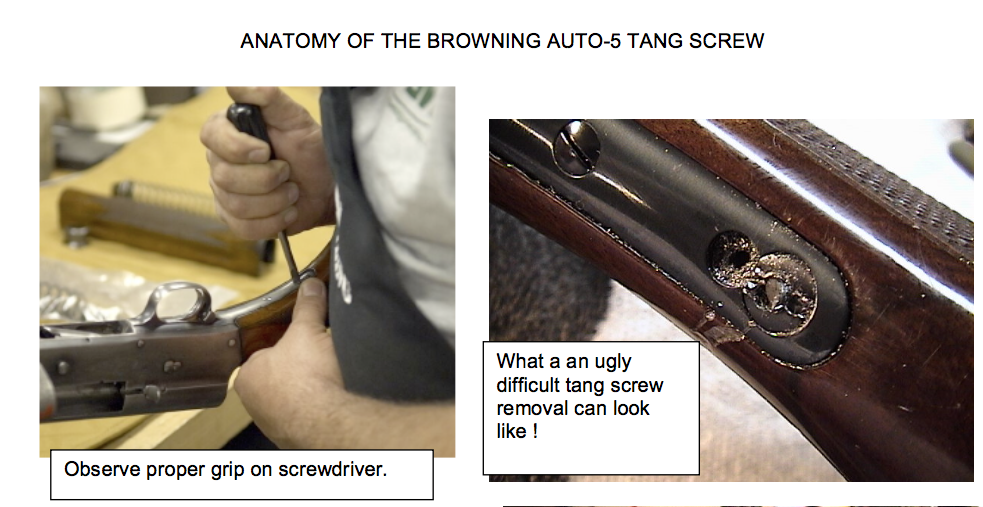

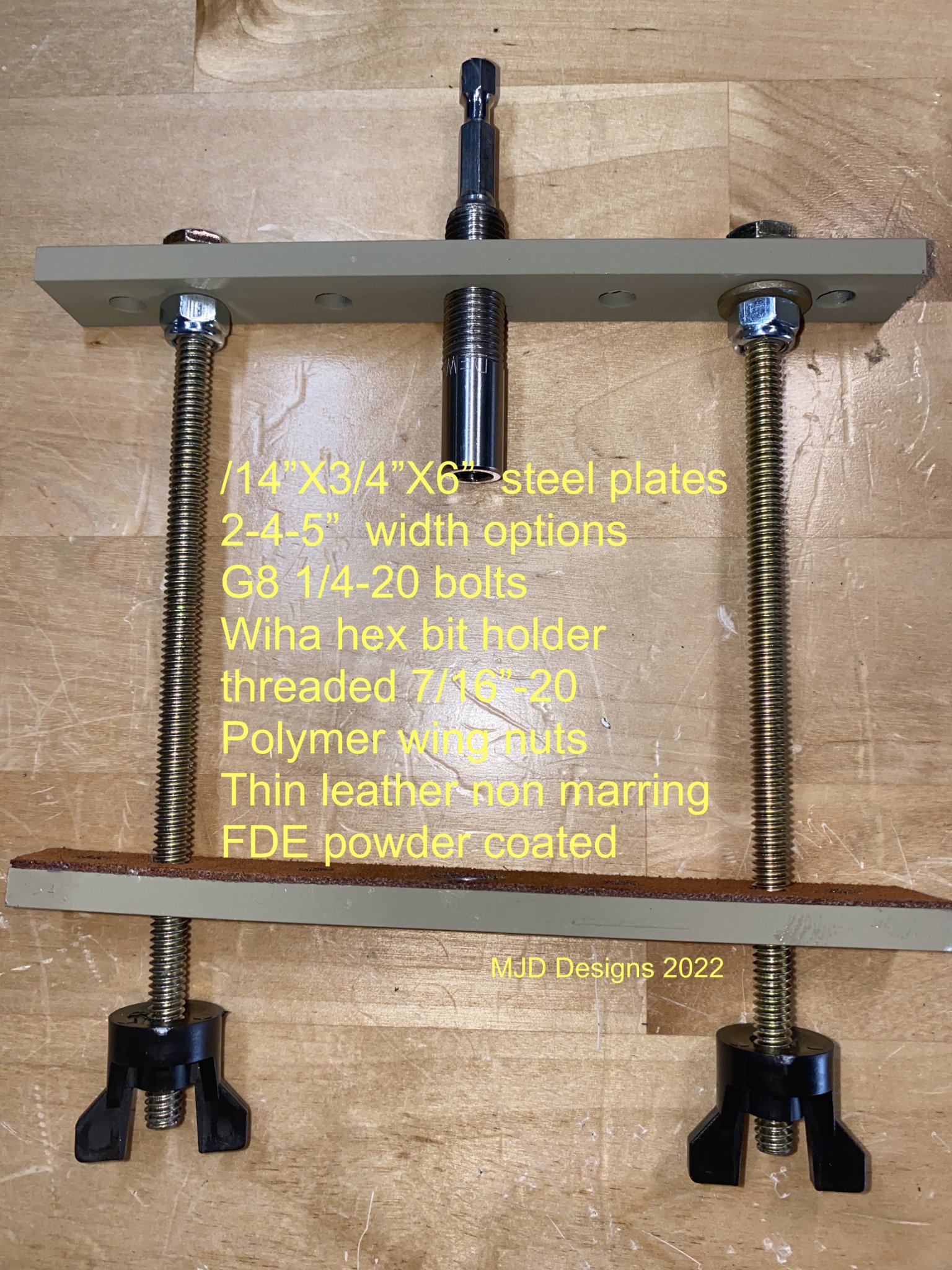

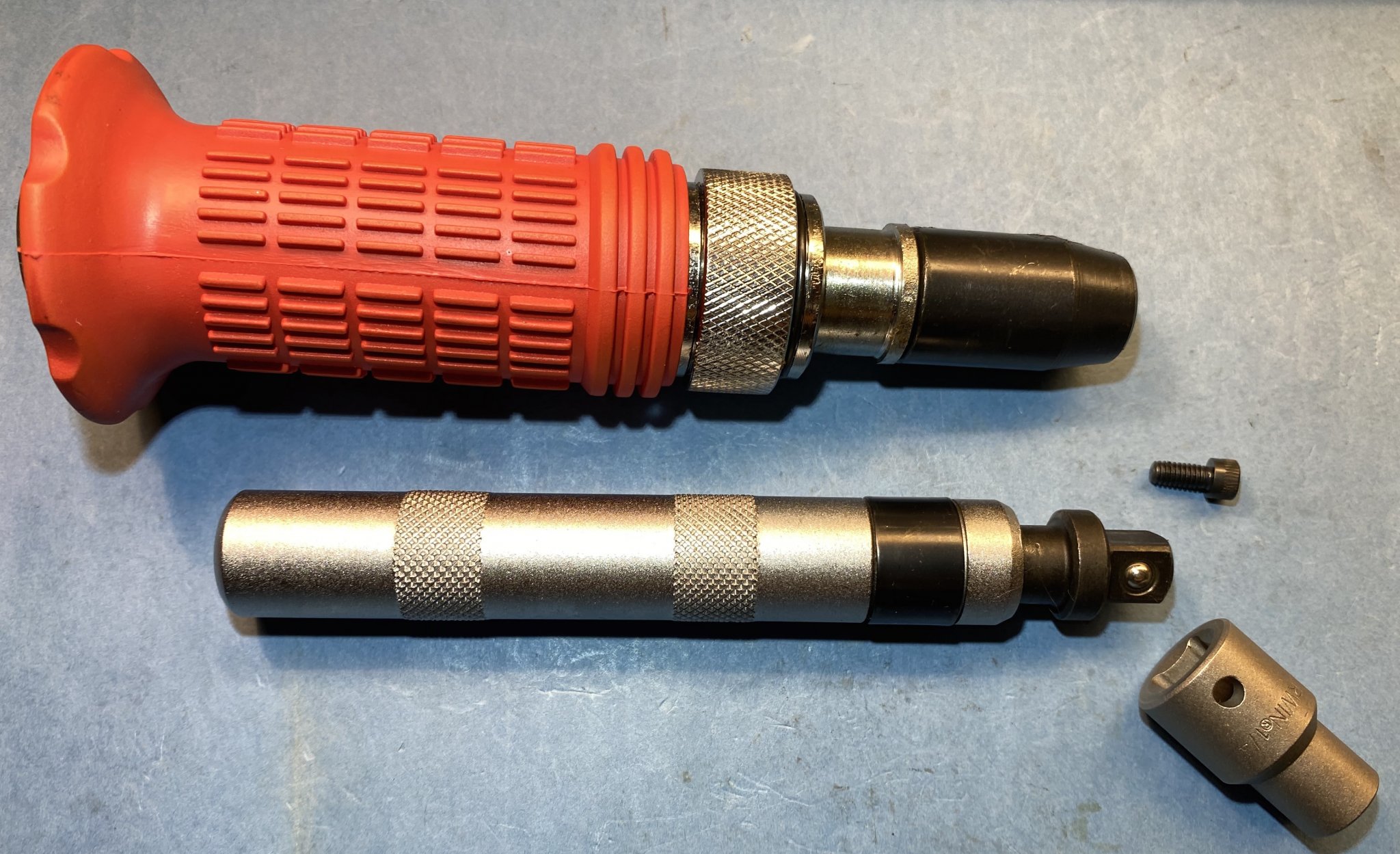

Some repetitive ideas; these are some of the technique tips I use for the difficult-to-remove gunsmith screws, unknown whether an adhesive was used (Loctite styles, heat sensitive, Rocksett style, heat insensitive until ~2,000 deg F.) Hollow ground tips an absolute must; screwdriver grip important (Browning master gunsmith demonstrating what LongRifle was referencing); direct application heat I prefer a shaped soldering iron tip that lessens the chance of marring any adjacent beautiful blueing finish, solder melting at Loctite temps; Laser micro impact driver ( used for some motorcycle applications, the key is it will hold all the Brownell hex screw driver bits and its profile allows for use in close quarters, like scope rings / bases), common size impact driver shown for comparison; old school screw jack ( guarantees the proper bit-fastener slot engagement )that I have fabricated a few different variants for really difficult super thin upscale European slotted screws. Patience is your friend, always screw up the least expensive part or the easiest to replace part first!

Heat application method: real time, the solder smoke is just about the same timing as loctite smoking LongRifle referenced.

www.dropbox.com

www.dropbox.com

Heat application method: real time, the solder smoke is just about the same timing as loctite smoking LongRifle referenced.

Dropbox

Last edited:

Hi strikeeagle1,Some repetitive ideas; these are some of the technique tips I use for the difficult-to-remove gunsmith screws, unknown whether an adhesive was used (Loctite styles, heat sensitive, Rocksett style, heat insensitive until ~2,000 deg F.) Hollow ground tips an absolute must; screwdriver grip important (Browning master gunsmith demonstrating what LongRifle was referencing); direct application heat I prefer a shaped soldering iron tip that lessens the chance of marring any adjacent beautiful blueing finish, solder melting at Loctite temps; Laser micro impact driver ( used for some motorcycle applications, the key is it will hold all the Brownell hex screw driver bits and its profile allows for use in close quarters, like scope rings / bases), common size impact driver shown for comparison; old school screw jack ( guarantees the proper bit-fastener slot engagement )that I have fabricated a few different variants for really difficult super thin upscale European slotted screws. Patience is your friend, always screw up the least expensive part or the easiest to replace part first!

Heat application method: real time, the solder smoke is just about the same timing as loctite smoking LongRifle referenced.

Thank you for your sharing, a real gunsmithing masterclass.

It’s nice to see the evolution of your « gunsmithing vice », last one with FDE powder coating

Last edited:

Similar threads

Sidearms & Scatterguns

Sig just can't get out of their own way

- Replies

- 12

- Views

- 1K