I've had this Lee Factory Crimp Die for .308 sitting around, and I thought I would experiment with it. I have some rounds loaded up and I thought I would put a light crimp on about 10-15 of them to see if this affect velocity or accuracy.

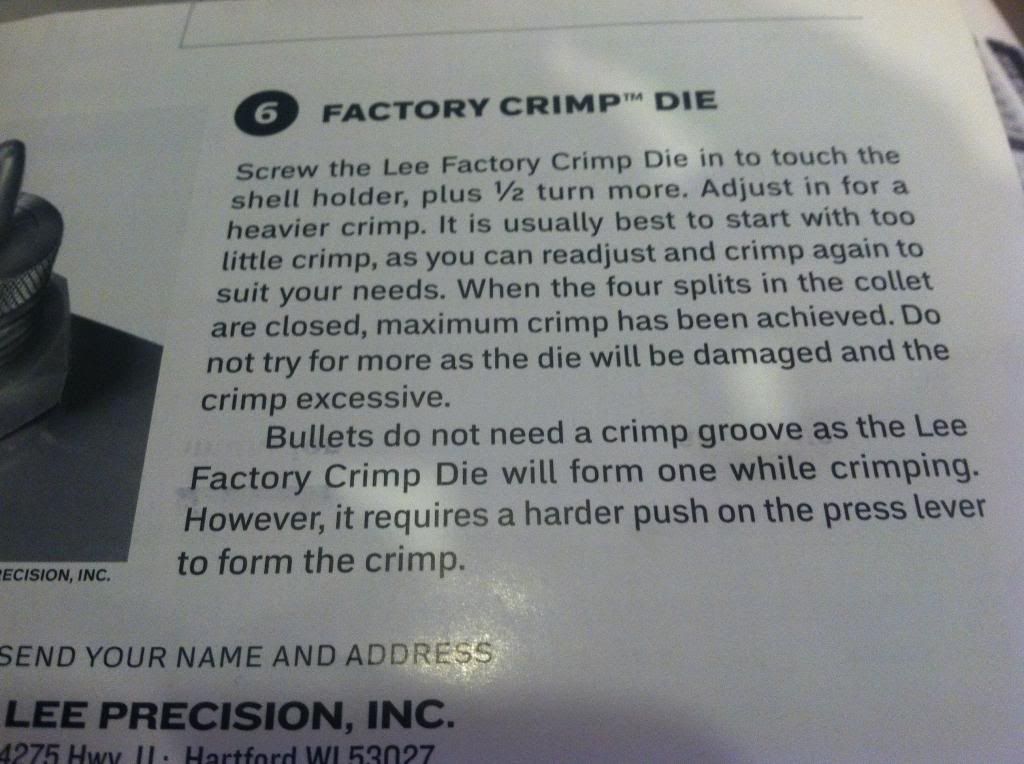

Problem is, the die isn't crimping anything. I screw the die down until it touches the shell holder, then another half turn, per the instructions. But when I run a round up through the die, nothing happens. No crimp and no marks whatsoever on the top of the case neck. I tried turning the die down another half a turn and still nothing. I don't know how that would do anything anyway, since the bottom of the die contacts the shell holder, so the only thing that screwing the die down further would do is prevent you from raising your press ram up further. And yes, I am applying the necessary 25 lbs of pressure.

Any ideas on what I am doing wrong? Or do I have a bad die?

Problem is, the die isn't crimping anything. I screw the die down until it touches the shell holder, then another half turn, per the instructions. But when I run a round up through the die, nothing happens. No crimp and no marks whatsoever on the top of the case neck. I tried turning the die down another half a turn and still nothing. I don't know how that would do anything anyway, since the bottom of the die contacts the shell holder, so the only thing that screwing the die down further would do is prevent you from raising your press ram up further. And yes, I am applying the necessary 25 lbs of pressure.

Any ideas on what I am doing wrong? Or do I have a bad die?