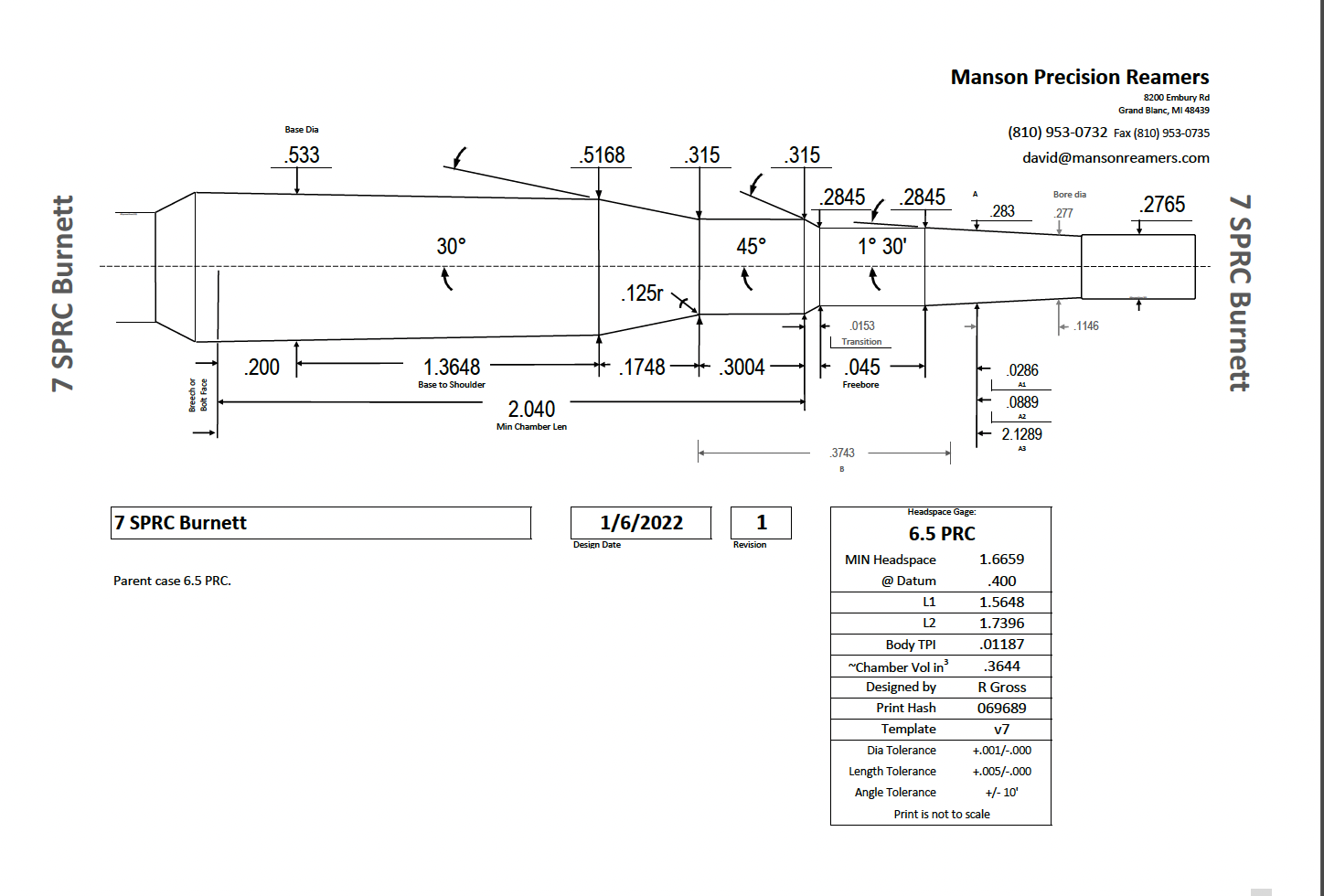

Since the 6.5 PRC came out, I have wanted to neck it up to 7 and make a 7mm-08 big brother in a SA. I finally got all the components assembled and sent them to the gunsmith. After two years of plotting and planning, I fired the first rounds last week. The results are encouraging thus far, however it's not without some measure of disappointment and I am now trying to understand what I did wrong. When Manson drew my reamer, it was with the understanding that the COAL had to be <2.95, so SA. We started with a SAAMI 6.5 PRC print, blew out the mouth to accommodate the 7mm, and cut the freebore down to a short 0.045. In my mind, I was wanting to get a COAL in the 2.96 region so I could have ~0.010 jump at mag length. Instead, the 166 ATip sits at a CBTO/COAL of 2.477 / 3.170, the 168 VLD at 2.478 / 3.158, and the 180 Hybrid (what we designed the cartridge for) at 2.521 / 3.208. This produces jump values of 0.22, 0.208, and 0.258 respectively. Clearly I "missed the target." The gun seems to be shooting, but I'm more concerned with why this happened. How does one reconcile the COAL / jump / target length relationship so that proper planning can be achieved? My next wildcat will likely be something like a 7mm 30cal magnum (PRC, WM, etc.) where an extra 1/4" could hurt me in terms of the overall usability of the rifle.

Would making a dummy round and sending it to the reamer manufacturer be the more reliable way of doing this? It would be using virgin brass, but it seems that would be more effective than going the reamer print > die > brass direction

Would making a dummy round and sending it to the reamer manufacturer be the more reliable way of doing this? It would be using virgin brass, but it seems that would be more effective than going the reamer print > die > brass direction