Re: Zenbiker's .408 Suppressor Build

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: KYS338</div><div class="ubbcode-body"> Not to poop on your parade....... but with only 3 baffles, that is not going to quiet a 408CT down that much. I would shrink those spacers down and try and get a few more baffles in it. Also, might consider getting some inconel or Ti and making a nice deep dish blast baffle. </div></div>

I guess I wasn't clear; this was just to show the baffle design; the blast baffle will be 17-4 and I will have a minimum of 6 wipes. You are completely correct, my bad for not being clear enough.

Will be starting on the muzzle end this afternoon, timer permitting.

Rolling Thunder, those x-ray views are great, thanks, but in all honesty, I have to pick a design that is in my current skill set; my time at the lathe is also limited by my neck.

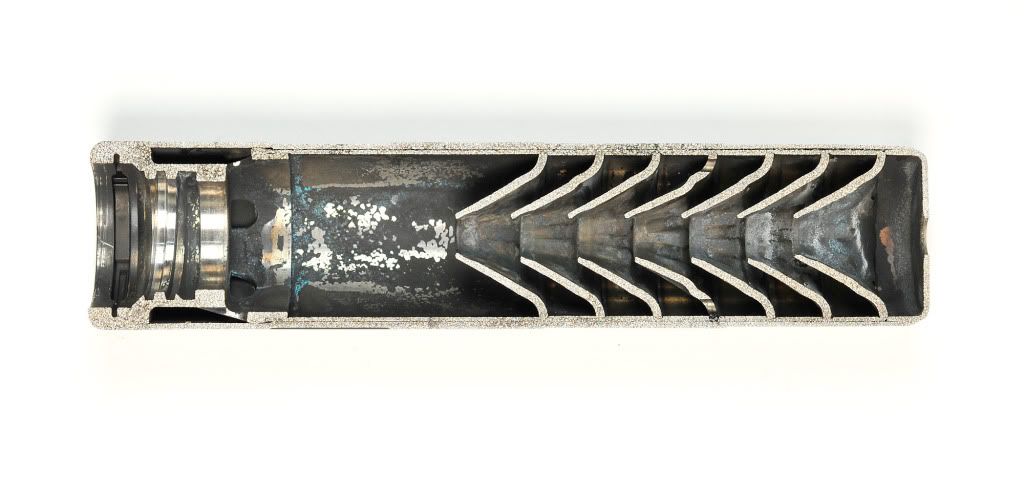

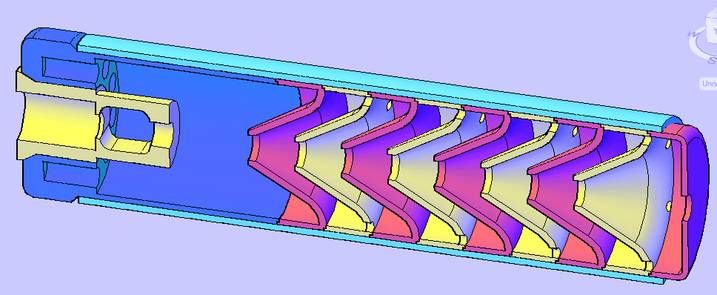

The blast baffle design is what I call a "muzzle brake in a can" and is going to be similar to this pic I stole from a member's 5.56mm build over on SilencerTalk:

The brake section threads onto the muzzle and into the larger round blast baffle. The bullet travels through the brake which will end flush with the front of the blast baffle. Gases from the brake will vent through circumferenctial holes in the front of the blast baffle. From there, it's up to the wipes, or silencer baffles, to hush the gases. The stepped design of the silencer baffles created turbulence that a smooth K type baffle would not. I've been racking my brain on some type of monocore baffle, and haven't ruled that out. I've also considered using titianium, and have a good supply of Ti-6Al-4V, but from what I've read, titanium is a a very elastic metal when machined, deforming then yielding, leaving a ragged cut unless the proper lubricant is used in a flood coolant system. Being on disability and a budget, I've got a flood system, but have not set it up yet.

Last, this project is now close to 6 years in the making; I'm not in a hurry; I can make a brake and shoot my rifle just fine. Like my sig line says, some jerk damn near broke my neck in a BJJ demo in 2007, and I'm just now getting back to where I want to live. This is one of my bucket projects, and I'm hoping that I can find enough real machinists and gunsmiths here to throw me a bone when I need it. My rifle was built by Lawton; I "knew" Barney before he passed and he was a helpful, kind gentlemen's gentlemen. It's in one of KLR Industries folding aluminum chassis stocks with a NightForce 5.5-22 X 50mm scope and a Jewell Trigger. I just got 100 rounds of DTC ammo, and along with a cache of brass, bullets, and dies, reamers, and gauges, represents the biggest investment in any single firearm in my possessesion; hell, if I did the math, it probably surpassess the sum of all my others combined, and next to my SA XD45 is undoubtedly the pride of my safe. I have an 1800 meter range, and just discovered one at 2200+ yards. Nobody will be calling me to Afghanistan to pop bad guys, but it's the culmination of two decades of desire since I shot my first 1000 yard match at Pennsylvania and spent untold hours in groundhog fields working on unknown distaance shooting, and working on this keeps my mind off the pain of my injury.

So I'm way past being bothered by a little poop, although I do have my days, and even haters can be helpful without knowing it

. Anyways, I'm looking forward to building this supressor here, and hope I can get some help and guidance when I need it, either knowingly or unknowingly. This is a great community with a lot of awesome information and very helpful people. Thanks again in advance for any help that anyone cares to offer.