Table of Contents:

1) Table of Contents

2) Background on ARC

3) Unboxing, Contents, Disassembly, and Impressions

4) Claims

5) Testing of Claims

6) Summary and Conclusion

Background:

I first became aware of Bobro’s products when reviewing the first GRSC scope for Ed Verdugo. The scope that he sent me for that review was a prototype and was in his personal mount. I remember he specifically mentioned the mount at the time he sent me the optic. He was quite taken by Andrew’s products in general and particularly happy to have this mount because, due to the modular construction, the throw lever could be reversed. This was a necessity on one of his rifles. For my part, I was quite taken with the throw lever design. It was an easy-to-use locking system that did not mar the rail or require readjustment for slightly out of spec rails. It also seemed to grip quite firmly. All of these were improvements over other designs I had tried. There were only two things I did not like about that early incarnation of the product. The first was that you could not get the torque wrench on all the bolts. That issue has since been addressed. Secondly, I was not a big fan of the styling. I’m still not really a fan in that regard. I don’t know what it is, just sort of a biliousness or perhaps ponderousness in the appearance.

Appearance aside, I’ve been watching Bobro for the last four years. With little or no marketing (they don’t even have a SHOT show booth), I have seen the company grow by word of mouth, Ed’s mouth maybe, from a few isolated users to an OEM of Trijicon branded mounts. They did all this while having a website that, to my knowledge, has never even been up to date with their product offerings. In other words, the products sold themselves. Demand has been such that the less common mounts have always been in and out of stock and the bipod, well, just forget about finding the bipod. This high demand may have kept the website from being updated but it does not seem to have stopped product improvement or new designs. I mentioned the updated nut location and this review is of an entirely new cantilevered 34mm mount.

That brings me to how I came by this mount…. I begged. I was doing the 1-8x scope showdown and was coming up a bit short on the mount end. To run a good close quarters speed testing section, I need all optics to be in a mount simultaneously so that they can be quickly swapped. Despite burrowing from all my buddies, and dismounting pretty much everything I had, I was still short one 34mm mount for the Bushnell SMRS. I wrote Andrew and begged. The timing happened to be perfect as Andrew had been developing a cantilevered 34mm variant and was looking for some exposure for it. He turned one out and had it to me within a week. This is a great benefit of being a business that actually makes and develops the products you sell in a factory in the U.S. that you drive to every morning.

Unboxing, Contents, Disassembly, and Impressions:

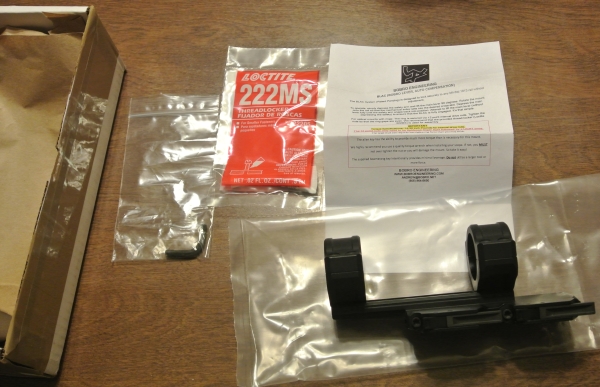

The mount came to me with a small vial of Loctite (which I do not use), a single-sided instruction sheet, and the strangest little 1/2″ by 1/2″ hex wrench. The instructions explained this – it’s to keep you from manhandling the cap nuts and breaking your scope. Aside from a quick explanation of how to use the lever system, this is what the short instructions focused on. ‘We recommend you use a torque wrench, but if you don’t have one, don’t just go looking around for a bigger hex wrench. We know what you are thinking: you want to use this big hefty mount to crush your cheap scope and blame us. We will not supply you the tool for accomplishing this. Furthermore, we have made the studs long enough that as the scope is tightened down you will get less and less purchase inside the nuts with your wrench so it will be harder to crush your scope. We have done all we can to prevent your idiot self from screwing things up.’ Okay, I’m paraphrasing. The instruction sheet was not written by me and they were nicer about saying things, but I can guess what they were thinking having had similar thoughts myself.

Aside from my impressions on the nature of idiot-proofing the design, the biggest single impression I had during the unboxing was that this thing is huge and heavy. I have mentioned during my 34mm 1-8x scope reviews that the downside of 34mm designs is that the added size tends to add weight to the optic as well as the mount. This mount is a great illustration of this. The 30mm Bobro cantilevered mount I first used four years ago was 6.9oz, which was exactly the weight of the competing Larue. This one weighed in at 12.3oz, easily the heaviest mount I have ever used and very close to the weight of ultra high 34mm steel Badger Ordnance rings. I will mention that the mount in this review is a prototype and that the production versions weigh slightly less. I understand that this is a tricky thing to criticize since many 34mm scopes are quite heavy and many rifles kick with great vigor. The largest contributing to the need for strength, which will add weight, is probably the fact that this is a cantilevered mount. Any engineer knows that, in order to hold the same load as a beam supported on both ends, a cantilever must not be twice as strong but rather significantly more than that. This applies to cantilevered mounts as well. It is the cost of getting the extra two inches of eye relief that the cantilever allows. Many scope makers seem to have adopted the thought that longer is always better with regard to eye relief so this is increasingly necessary.

The finish of the Bobro is black anodizing of the highest quality, similar to that of the ARC mount previously reviewed. The machining is also excellent and clean, with no tooling marks remaining. Between these two designers there is a major difference in strategy and goal that should be addressed. The center section of the American Rifle Company mount included the ring bottoms in what was a very unified system aimed at eliminating all fasteners that would never be utilized by the end user to add stiffness and precision. This Bobro design, and Bobro designs in general, are modular in design. The rings are separate from the backbone and in some designs, though not this one, the backbone is also separate from the base. The idea of this modular construction is to lower cost and increase the options available by making parts interchangeable. Any rings can be mated with any backbone and, in the more common single lever models, with any base. This is how Ed was able to reverse the lever in his 30mm mount. He reversed the direction of the base component as well as that of the forward indexing cross slot lug. In this 34mm variant, the base and backbone are one piece since not enough vertical room existed to make a joint and added stiffness was needed in the design to accommodate heavy scopes and violent rifles. Nevertheless, any rings could be dropped on top.

Claims:

Andrew is quite up front with the claims for his locking system. They are clearly listed on the website and are as follows:

1. Must be compatible with any 1913 Specification Rail, to include systems that are out of specification (within reason) and this includes Weaver rails.

2. Must be completely user adjustable, tool free. It needs to be 100% self-contained and mate securely to any rail without the user having to tailor the pressure/engagement position.

3. Must lock with enough pressure to positively attach any device or optical instrument to a rail without movement, static or dynamic forces not withstanding.

4. The rail must not experience any deformation due to user error. This must include synthetic (plastic/polymer/composite) rail systems.

5. Auto Index capability. The device must also index parallel to the bore. The unit must always repeat the forward shift (recoil forces direction of influence) not only to maximize zero repeatability, but to take this step of installation out of the user’s initial mounting sequence. Index must be redundant.

6. Unit must not shoot loose due to improper mounting or a mechanical bottoming out.

7. The system must incorporate a safety that prevents the lever from being accidentally opened. The safety must be able to be manipulated in conjunction with the lever rotation, so that only one hand is required to open it.

8. The unit will utilize constant force to ensure required pressure in all conditions. The force must be substantial to prevent any shift forward/aft left/right.

9. The pressure must be applied in a linear direction centered in the main body to prevent cocking of the mount.

10. It must be easy to manipulate by gloved or fatigued hands.

11. It must be extremely robust, and withstand shock and impact to the system housing.

Many of these claims such as 2, 7, and 9 are more design specifications than testable claims. It is obvious from the pictures that the design meets these specifications. I will boil the others down to three claims, flatly ignoring claim 11 because I’m not about to go at it with a hammer or drag it behind my truck. Here is my Readers Digest version of the testable Bobro claims:

a. Will fit on any in-spec rail without adjustment and not mar.

b. Will return to, and hold, zero.

c. Can be attached and detached with a single gloved hand.

Testing of Claims:

In order to test the fit any in-spec rail without marring claim and gloved hand claim, I attached and detached the mount from a variety of rails: polymer, steel, and aluminum. A single, gloved hand is not an issue. The levers have plenty of purchase. Similarly, no in-spec rail presented any size difficultly. On the out of spec rails I tried, two problems came up. First, some rails have cross slots that are not the correct width. This has been a problem before for me as many rings have cross slot engagement that also requires in-spec rails. Bobro has a little leeway in this department because of its forward indexing cross slot lug. This lug has a spring loaded arm on the back that forces the mount to always index forward. Still, I did have a rail on hand that was just too far below spec on cross slot thickness in this department for the mount to fit on without a little file work on the out of spec rail. On significantly oversized rails, I believe the bobro will probably also not fit. The fit is snug on a rail I have that is right on spec but has been painted. There is some room for an oversized rail, but not all that much. As to an undersized rail, I have a significantly undersized rail for testing and the Bobro gripped it plenty tight. Lastly, no mar was noticed on any rail, even the polymer accessory rail I tried. Some of the competing products will not mount on all the different, and out of spec, rails I tested on and some will only mount with a good deal of wrench adjustment in between.

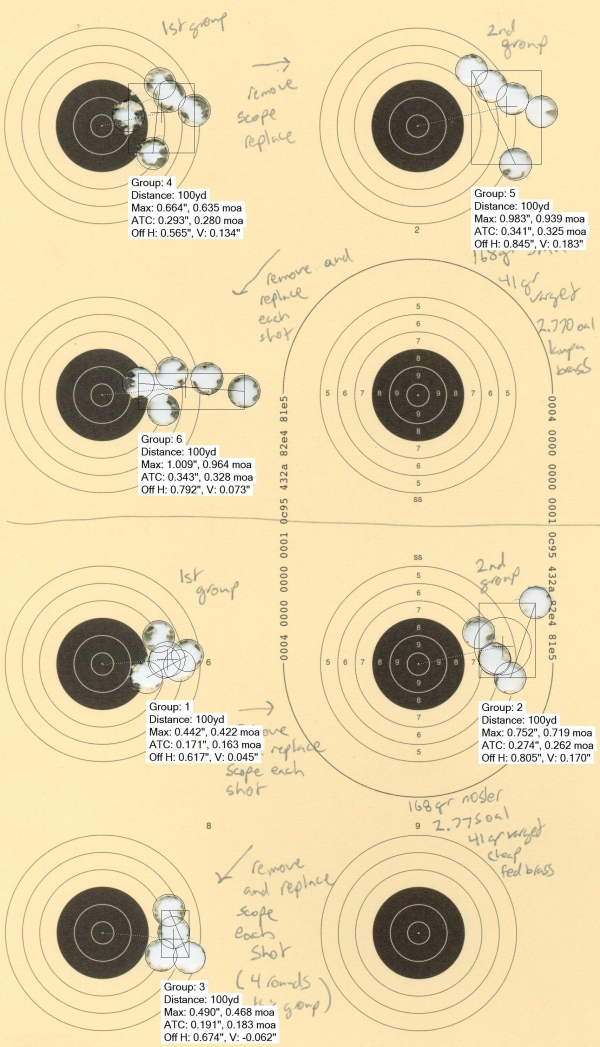

Now we get to the meat of the testing: Will it hold zero and will it return to zero? Throughout the course of my testing I used both the original Bushnell SMRS 1-8.5x scope and a U.S. Optics ER-25 scope. This mount does feature enough distance between the turrets to fit a T-pal saddle section comfortably. Both optics were torqued to 20 inch/lbs. The test targets below were fired with the high powered USO scope. All were fired from a Patriot Arms (APA) .308 rifle and two different loads were used for the different groups as marked on the target. One of these was a fresh loading of the same Nosler 168 based load that I used for the American Rifle Company review. The other was a new Sierra 168 SMK based load that I had high hopes for, but sadly proved to be a poor load. Groups were fired from a bench at 100 yards with front and rear bag in about 70 degrees with variable winds to about 4 mph.

Before we analyze the targets, let us talk a little about a mount or rings returning to zero after being dismounted and remounted. I think the first thing to say is that there are really no such things as mounts that return to zero and those that do not. What do exist are mounts offering different degrees of average change in point of aim after a mount is dismounted and remounted. The idea is to get as little average change as possible. Most companies advertising a QD product that “returns to zero” do not specify how much change is expected and tolerable and, therefore, amount to meaningless statements. Some, notably GDI, do (in their case, .1 MOA in lab and <.2 in field testing). That degree of repeatability would be good enough for probably any use shy of benchrest, whereas the 1 MOA claim that I have heard others informally bandy about for other makers, while it might suit the AR crowd, would not please most precision rifle users.

A number of things matter when it comes to return to zero and not all of them are the province of the rings or mount. In order to make a scope’s new location, after remounting, as close as possible to its original location; it is most advisable for the designer of the mount to try to make all the variables effecting this as repeatable as possible. These variables include gripping force, position, and deformation of the parts involved. Bobro’s design, with its precisely calibrated spring tension and tight cross slot engagement, seeks to minimize any changes to these variables.

In order to test the return to zero capabilities of the Bobro mount, I fired three groups with each ammunition at 100 yards. I started with the SMK based ammo that I had hopes for and shot two five shot groups dismounting and remounting the scope in between. I next shot a third five shot group dismounting and remounting each shot. These groups were less than I expected, so I switched to the ammo that was a known quantity and did three more. This time I shot the first group and for both the second and third groups I dismounted and remounted each shot. The final group was only four rounds as I was out of the Nosler ammo at that time.

In order to better analyze the resulting targets, I used the OnTarget program. This program calculated a variety of statistics for each group. Of most interest are the horizontal and vertical offset from aim point statistics. By comparing each groups offsets to those of the other groups, the displacement from the center of one group to another could be calculated and from that, the average displacement calculated. With the SMK based load, the average group-to-group shift in the calculated center was .214″ and this when the average displacement of a shot from the center of its group was .326″. With the Nosler based load, the average group-to-group shift in the calculated center was .205″ and this when the average displacement of a shot from the center of its group was .212″. What does this mean? I could go dig up some equations for standard deviation and try to figure out if the deviation in calculated group centers can be said to be great enough to reasonably exclude chance alone, but, given the small number of data points, I think that I would only end up finding I had a lack of data and couldn’t say much of anything with reasonable confidence. This will not keep me from speculating. People have to make decisions with insufficient information all the time. These decisions are alternately referred to as judgments when they go right and luck when they go wrong, relative to the observer. Most of the best paid people in the world are engaged almost solely in this type of decision and you can guess what my philosophical opinion on that is. Since I would like to be as well paid as, say, a Goldman Sacs analyst; I will give you my opinion and then you can risk your money and pay me a big chunk regardless of performance. I think that performance of the Bobro mount returning to zero and holding zero is good enough for any non-benchrest use. The groups fired dismounting and remounting the scope each shot did not open up significantly when compared to those fired with the scope mounted throughout. Furthermore, having used the Nosler load in conjunction with this rifle and a number of different mounting systems in the past, some quick-release and some not, I can say that the groups fired with the Bobro are not larger than those fired using traditional rings. Actually, the .442″ group is the smallest with that load to date.

Summary and Conclusion.

Bobro is one of my favorite makers of quick-release mounts. I regularly recommend their single lever 30mm mounts to AR users. It is the best affordable, cantilevered, quick-release system made. It is exactly what most AR users are looking for – or would be if they were willing to spend more than $50. Today’s 34mm mount is something of a hybrid of the cantilevered quick-release mounts common to AR users and the precision optic uni-mounts that many bolt gun users have. Bobro doubles up the levers to handle heavy recoiling loads, adds 34mm rings, and stiffens the backbone to base juncture by making it one piece, all while keeping the cantilevered nature. I am pleased that Bobro also accommodates the large saddle section of USO T-Pal scopes in this design.

The design performs as advertised. It is solid and I have no qualms about its ability to hold and return to zero. For those who like to pull their precision rifle optic from time to time and mount it on an AR, this is an excellent option to consider. It may similarly be seen as an excellent option for the now plentiful 34mm. The cantilever will also be appreciated by those who have long necks but not so long arms, as traditional rings often cannot be mounted far enough forward on a properly sized rifle to get proper eye relief when shooting prone. Many folks end up increasing length of pull to ridiculous degrees to compensate for this and then having problems with that long ass rifle held out in off-hand shooting.

Even so, not everything about the Bobro drop forward 34mm mount is ideal. At around $325, it is well up into the top price bracket for mounts, but it lacks a few of the extras becoming more common in premium precision optics uni-mounts. Plenty of room exists at the rear of the base for a bubble level, but none is present. That big, wide, flat space at the back of the base just looks so desirous of a small bubble level. Similarly, a mounting point is not present for an add-on angle cosine gauge. Alternate ring caps are slated to be available to connect the small red dots popular with many shooters though. The weight is a substantial consideration as well. Certainly the cantilever design and quick-release system add some weight, and that weight may simply be the cost of having these features: features that if you weren’t interested in you wouldn’t be reading this. All in all, it is a solid design. Though a few alterations could make it even more attractive.