Hello all, I've been reading here for a while, but this is my first post. I've read several other threads with similar issues, but every situation is different, so I figured I'd ask about my own situation.

Currently equipped:

PSA upper and lower receivers

BA 18" Stainless .223 Wylde rifle-length barrel

Toolcraft nickel-boron BCG

Aero Precision stainless rifle-length gas tube

No name basic .750 gas block

Tubb flat buffer spring with 2-3 coils removed

Odin adjustable buffer, currently about 2 oz

Rise RA-140 trigger

Strike ambi mag release

I have what started out as a basic PSA 16" carbine-length 5.56/.223 AR. First upgrade after about a year was a Rise RA-140SST drop in trigger. I was never happy with the accuracy of the barrel, so I was leaning toward a Faxon or BA 20" rifle-length .223 Wylde. JoeBob's had a great deal on an 18" BA rifle-length stainless barrel, so I jumped on that, with a Kaw Valley gas block and JoeBob's stainless gas tube. I dimpled the barrel for the gas block using a Kaw Valley dimpling jig. Also swapped to a Toolcraft nickel-boron BCG at the same time.

First time firing it, regardless of ammo type, it was short stroking and not locking back on an empty mag. Gas was blowing out everywhere around the gas block. I contacted Kaw Valley, and they sent out a replacement gas block. This one seemed to seal properly, and factory Norma 55gr .223, Winchester 55gr 5.56, and Winchester 62gr 5.56 all cycled properly and would lock back empty, as would a CFE223 55gr FMJ @ 26.3gr load. However, 55gr FMJ over 22.4 H335 and 24.0 AR Comp that ran reliably with the original 16" barrel would not lock back, and the AR comp was hit or miss whether it would cycle a subsequent round reliably.

I swapped out the buffer spring and buffer for a Tubb flat spring and Odin adjustable buffer. Tried various weights from 1.5oz to 4.5 oz, with no change. I tried 2 different BCGs, with no change. Tested the BCG with bolt removed to check gas tube fit, no issue. Tested to make sure the gas block was aligned (though the dimpling jig ensured it would be, and removing the block I could see the holes matched up perfectly) by blowing air through with the barrel plugged. Gas key is tight and properly staked. Thoroughly lubed the bcg.

Around this time, I also tried new, hotter H335 loads, from 24.3-25.2gr, with no change to cycling at all.

Called Tubb to see if they have a lighter weight flat spring, and was advised to try cutting off 3 coils. Swapped out to a basic, no-name gas block my buddy sent me to try, with a new Aero Precision gas tube installed. The new gas block actually had a much tighter fit around the barrel journal than the Kaw Valley did, so I was encouraged. Tested these changes today at the range, but no real change.

No real change, although today at the range for some reason the bolt wouldn't reliably lock back on any ammo but the CFE223 reloads, and wouldn't even reliably lock back when I cycled the bolt via the charging handle on an empty mag. I also was able to chrono the ammo I shot today - factory loads were 3000-3100fps, H335 22.3gr was around 2700fps, AR Comp 24.0 gr @ 3000fps, and CFE223 26.3 @ 2800fps.

I am pretty certain there is no real problem with the lower, as I have a PSA 16" 300blk upper that I also shot the same days on it, and it cycled reliably no matter what changes I made to the spring or buffer.

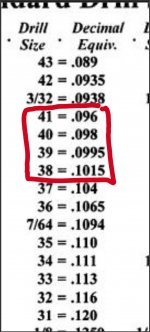

At this point I am at a loss. The only other thing I can think to try is to have the gas port enlarged from the 0.093" it is now to something larger, maybe 0.100"? I will try spinning the bolt in the chamber to ensure it turns freely, but that's about the only thing I've read on other threads that I haven't tried. My LGS and the gunsmith at the range were stumped as well.

Does anyone have any other ideas of anything I'm missing?

Currently equipped:

PSA upper and lower receivers

BA 18" Stainless .223 Wylde rifle-length barrel

Toolcraft nickel-boron BCG

Aero Precision stainless rifle-length gas tube

No name basic .750 gas block

Tubb flat buffer spring with 2-3 coils removed

Odin adjustable buffer, currently about 2 oz

Rise RA-140 trigger

Strike ambi mag release

I have what started out as a basic PSA 16" carbine-length 5.56/.223 AR. First upgrade after about a year was a Rise RA-140SST drop in trigger. I was never happy with the accuracy of the barrel, so I was leaning toward a Faxon or BA 20" rifle-length .223 Wylde. JoeBob's had a great deal on an 18" BA rifle-length stainless barrel, so I jumped on that, with a Kaw Valley gas block and JoeBob's stainless gas tube. I dimpled the barrel for the gas block using a Kaw Valley dimpling jig. Also swapped to a Toolcraft nickel-boron BCG at the same time.

First time firing it, regardless of ammo type, it was short stroking and not locking back on an empty mag. Gas was blowing out everywhere around the gas block. I contacted Kaw Valley, and they sent out a replacement gas block. This one seemed to seal properly, and factory Norma 55gr .223, Winchester 55gr 5.56, and Winchester 62gr 5.56 all cycled properly and would lock back empty, as would a CFE223 55gr FMJ @ 26.3gr load. However, 55gr FMJ over 22.4 H335 and 24.0 AR Comp that ran reliably with the original 16" barrel would not lock back, and the AR comp was hit or miss whether it would cycle a subsequent round reliably.

I swapped out the buffer spring and buffer for a Tubb flat spring and Odin adjustable buffer. Tried various weights from 1.5oz to 4.5 oz, with no change. I tried 2 different BCGs, with no change. Tested the BCG with bolt removed to check gas tube fit, no issue. Tested to make sure the gas block was aligned (though the dimpling jig ensured it would be, and removing the block I could see the holes matched up perfectly) by blowing air through with the barrel plugged. Gas key is tight and properly staked. Thoroughly lubed the bcg.

Around this time, I also tried new, hotter H335 loads, from 24.3-25.2gr, with no change to cycling at all.

Called Tubb to see if they have a lighter weight flat spring, and was advised to try cutting off 3 coils. Swapped out to a basic, no-name gas block my buddy sent me to try, with a new Aero Precision gas tube installed. The new gas block actually had a much tighter fit around the barrel journal than the Kaw Valley did, so I was encouraged. Tested these changes today at the range, but no real change.

No real change, although today at the range for some reason the bolt wouldn't reliably lock back on any ammo but the CFE223 reloads, and wouldn't even reliably lock back when I cycled the bolt via the charging handle on an empty mag. I also was able to chrono the ammo I shot today - factory loads were 3000-3100fps, H335 22.3gr was around 2700fps, AR Comp 24.0 gr @ 3000fps, and CFE223 26.3 @ 2800fps.

I am pretty certain there is no real problem with the lower, as I have a PSA 16" 300blk upper that I also shot the same days on it, and it cycled reliably no matter what changes I made to the spring or buffer.

At this point I am at a loss. The only other thing I can think to try is to have the gas port enlarged from the 0.093" it is now to something larger, maybe 0.100"? I will try spinning the bolt in the chamber to ensure it turns freely, but that's about the only thing I've read on other threads that I haven't tried. My LGS and the gunsmith at the range were stumped as well.

Does anyone have any other ideas of anything I'm missing?