I previously had this barrel on a different upper during break in but wanted to switch to a San Tan upper for this build.

Barrel specs:

I already have about 150 rounds through this barrel and shot a sub moa 10 shot group during break in (zero load development)

Barrel specs:

- Weight: 42.8 oz

- Gas port: 0.093”

- Gas system: rifle +2”

- Zev 7.62 Flash Hider/Compensator ($29)

- CMT .750 JAG Set Screw gas block ($25)

Daniel Defense low profile .750 Clamp On Gas Block($60)- White Oak Rifle +2” Gas Tube ($17)

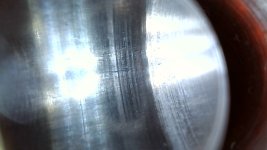

- Osprey 18” 6 ARC Rifle +2 barrel ($399) (+$125 with headspaced Rubber City bolt) (Total: $524)

- Rubber City M-16 Blacknitride+ Bolt Carrier ($80)

- San Tan Tactical Billet Upper ($175) (thermofit)

- SOLGW M89 15” Rail ($330)

- SOLGW Ambi Charging Handle ($80)

- Total: $1,295

I already have about 150 rounds through this barrel and shot a sub moa 10 shot group during break in (zero load development)

Last edited: