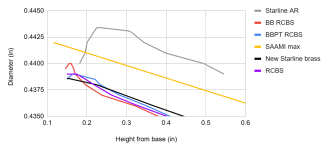

I concur with this based on my experience that after 10 firings every starline piece I have belted to the point of being unusable and my hornady is beat up but still not belted. Sgt of arms belt buster die and hornady watch grade 6mm arc die. Annealed every firing. Using LVR and TAC at max book loads for 105-110gr bullets CCI 450 or rem 7 1/2.Here's the external diameters of a case from each brand of brass fired in each barrel, along with the internal diameter of the chamber of each barrel. Note that the Starline brass clearly is getting pushed into the region at 0.20"-0.23" on the AR barrel where the case web has stopped but the chamber hasn't yet come in to support the case. In that region there's just a ~0.035" brass hoop holding in 52kpsi

View attachment 8678489

Charting each brand between the two chambers is also instructive. The extra bulge in the Starline AR brass vs bolt action is particularly notable. The Hornady brass avoids the same effect, clearly the increased web height, wall thickness, and radius between the two is putting in work.

View attachment 8678490

The pricey brass options both appear to do a good job of avoiding getting overly expanded into the AR chamber lead-in chamfer. On the Alpha the web and radius stop at 0.20" height so it's resisting this by wall thickness and brass strength. The Peterson web-to-wall radius goes up to 2.50" so there's a lot more brass mass in the region than on the Alpha.

View attachment 8678491

Overall takeaways for me from this is that the Starline and Alpha brass are really built for bolt guns. The Alpha seems strong enough to deal with the unsupported chamber region on an AR, but it's depending on an extra 0.005"-0.007" of wall thickness and superior material strength vs the Starline to achieve that, whereas the Hornady and Peterson brass have internal geometry (web height and web-to-wall radius) that appears specifically designed to work in an AR chamber.

Next time, sizing dies and sizing results.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6 ARC Gas Guns

- Thread starter steve101610

- Start date

I concur with this based on my experience that after 10 firings every starline piece I have belted to the point of being unusable and my hornady is beat up but still not belted. Sgt of arms belt buster die and hornady watch grade 6mm arc die. Annealed every firing. Using LVR and TAC at max book loads for 105-110gr bullets CCI 450 or rem 7 1/2.

You might find this next set of results particularly interesting.

I found that the Sgt. of Arms belt-buster die did some weird stuff, especially with Starline brass. After some experimenting I ended up using the belt buster as a pass-through die. This process is similar to bullet sizing, the goal is the same as rollsizing. I opened up the shell holder from a Redding G-Rx 40S&W/10mm passthrough base-sizing die set a little so it would hold an ARC case and mounted the belt buster die high enough in the press to get it to work. The G-Rx die has the sizing ring near the top of the die, but the belt buster die has it at the bottom, thus the need for weird mounting. Works though, and the sized case just sits in the die when you raise the press handle. I grab it when the next case pushes it up.

Okay, so what does it do? In the charts below, the yellow "SAAMI max" line is the maximum cartridge diameter dimension from the SAAMI print. The goal of sizing is the get the diameter of the case to be below this line, Up to 0.008" is within tolerance but anything below it is acceptable. If you want to work your brass the minimal amount and have the cartridge sit as tightly as it can (for potentially increased precision) while being in-spec, you want to be just under that line.

This shows the results of using just the belt buster as intended (bottoming out on a normal shell holder, "BB") and using the belt buster as a pass through die in the rig above ("BBPT), along with Starline brass when new and after firing in the AR:

Starline brass, fired in this barrel, expands well above of the spec diameter at a height well below where the belt buster can fully size when bottomed against a shell holder. The result is that used this way, on this brass, it leaves a belt at the bottom. Using it as a pass-through die gets the entire region under 0.33" under the spec diameter.

As a worst-case scenario for what happens when sizing this brass in an RCBS small-base full-length die, vs. the belt buster then RCBS die, vs. belt buster passthrough then RCBS.

Everything is in-spec, but the The BB+RCBS flow creates a pronounced bulge right at the top of the extraction groove. After several firings, this can grow until the rounds won't chamber any more. I don't use the BB die without pass-through anymore.

That said, the RCBS die is clearly sizing the brass much more than is needed to stay in-spec. Here's the results of sizing with just a full-length die and the BB pass through die + a full length die for Lee die and a Mighty Armory die:

both of these dies size to just under the maximum diameter, working the brass much less than the RCBS die. The BBPT+full length die still eliminates the minor belt at 0.2"-0.25".

Here's the full-length die only results from all three dies:

And for the BBPT+full-length die:

For using Starline in an AR, I prefer the BBPT+Mighty Armory setup with the BBPT+Lee in close second. As much as I want to run the Peterson all the time for its strength and consistency, losing pieces at gas gun matches makes me wince. This reloading flow seems to be a good way so far to use Starline in a more or less sustainable manner.

I gotta say that I've been impressed with the Lee sizing die for the money. Compared to almost everyone else they FEEL cheap and rough and almost unfinished. But sizing happens on the inside, and that surface is polished very nicely and dimensioned nearly optimally. Similarly, the expander mandrel is straight, smooth, strong, and well-polished. It's held in with a downright cheap-feeling collet screw, but it does the job.

Final note, the Hornady die has very similar sizing results to the RCBS one. I don't have that one anymore to get into this data set, but some of my older measurements definitely show it behaving like the RCBS die.

Attachments

Right now I'd go with Peterson. I don't have a bunch of firings on either yet, but it's just as consistent as the Alpha and the web is high enough that it shouldn't develop a belt even with the biggest chamber chamfer. Most important is to go with a sizing die that doesn't squeeze the brass too much at the base. The Lee works great and is very affordable. Stay away from the Hornady and RCBS dies on this cartridge.For an AR-15, which do you think is the best brass? Peterson or Alpha?

Thanks!

Next data set: measurements of the dies themselves. The SAAMI max and min lines are for the cartridge body.

The measurements of the Hornady die are incomplete as a took them before I decided to start measuring the lead in radius and got rid of it in the meantime. Nevertheless, you can clearly see that the Hornady and RCBS dies are about 0.004" narrower at the base compared to the the Lee and Mighty Armory ones.

The measurements of the Hornady die are incomplete as a took them before I decided to start measuring the lead in radius and got rid of it in the meantime. Nevertheless, you can clearly see that the Hornady and RCBS dies are about 0.004" narrower at the base compared to the the Lee and Mighty Armory ones.

Being a bullet caster and using Lee bullet sizing dies for powder coated revolver bullets, I am very familiar with using this type of die as a pass through. When I saw the Sergeant of Arms belt buster die for .441" cases I bought one.

I have hundreds of Lapua (AA) 6.5 Grendel cases that were unusable due to a very accurate but looser chamber Satern cut-rifled barrel. They would not fit in a Proof (or RTR, Rainier UM barrel) after being fired in the Satern. After being sized in the belt buster they were usable again.

My mind started having thoughts of using it as a pass through so I dug out a 44 Magnum ram from one of my Lee bullet sizing dies and snapped it into my RCBS Rock Chucker, lubed up a few cases, and ran them through the belt buster. A strong tabletop is necessary if you have an oversized chamber but the cases came out comparable to factory new Lapua. I have used the die this way ever since.

I will say you can tell a difference between brass brands as Lapua has always been the toughest to run through that die. Also, Hornady OneShot lube is not advised for this. Having sized hundreds of cases this way, I only use Royal case lube spray for this.

If you have a snug chamber and only use the brass for one gun this process is probably unnecessary. All of my .441" case head guns are AR's FWIW and I have more than a couple in each caliber so I go to the trouble. A boltgun would probably never need this amount of work either.

Like Padom mentioned above, I use LE Wilson FL bushing dies and 21st Century mandrels for my sizing. I do this whether it is for 6mm ARC or 6.5 Grendel and also anneal every firing. I don't loose cases to split necks even if the case head has Starline stamped on it.

I have hundreds of Lapua (AA) 6.5 Grendel cases that were unusable due to a very accurate but looser chamber Satern cut-rifled barrel. They would not fit in a Proof (or RTR, Rainier UM barrel) after being fired in the Satern. After being sized in the belt buster they were usable again.

My mind started having thoughts of using it as a pass through so I dug out a 44 Magnum ram from one of my Lee bullet sizing dies and snapped it into my RCBS Rock Chucker, lubed up a few cases, and ran them through the belt buster. A strong tabletop is necessary if you have an oversized chamber but the cases came out comparable to factory new Lapua. I have used the die this way ever since.

I will say you can tell a difference between brass brands as Lapua has always been the toughest to run through that die. Also, Hornady OneShot lube is not advised for this. Having sized hundreds of cases this way, I only use Royal case lube spray for this.

If you have a snug chamber and only use the brass for one gun this process is probably unnecessary. All of my .441" case head guns are AR's FWIW and I have more than a couple in each caliber so I go to the trouble. A boltgun would probably never need this amount of work either.

Like Padom mentioned above, I use LE Wilson FL bushing dies and 21st Century mandrels for my sizing. I do this whether it is for 6mm ARC or 6.5 Grendel and also anneal every firing. I don't loose cases to split necks even if the case head has Starline stamped on it.

Being a bullet caster and using Lee bullet sizing dies for powder coated revolver bullets, I am very familiar with using this type of die as a pass through. When I saw the Sergeant of Arms belt buster die for .441" cases I bought one.

I have hundreds of Lapua (AA) 6.5 Grendel cases that were unusable due to a very accurate but looser chamber Satern cut-rifled barrel. They would not fit in a Proof (or RTR, Rainier UM barrel) after being fired in the Satern. After being sized in the belt buster they were usable again.

My mind started having thoughts of using it as a pass through so I dug out a 44 Magnum ram from one of my Lee bullet sizing dies and snapped it into my RCBS Rock Chucker, lubed up a few cases, and ran them through the belt buster. A strong tabletop is necessary if you have an oversized chamber but the cases came out comparable to factory new Lapua. I have used the die this way ever since.

I will say you can tell a difference between brass brands as Lapua has always been the toughest to run through that die. Also, Hornady OneShot lube is not advised for this. Having sized hundreds of cases this way, I only use Royal case lube spray for this.

If you have a snug chamber and only use the brass for one gun this process is probably unnecessary. All of my .441" case head guns are AR's FWIW and I have more than a couple in each caliber so I go to the trouble. A boltgun would probably never need this amount of work either.

Like Padom mentioned above, I use LE Wilson FL bushing dies and 21st Century mandrels for my sizing. I do this whether it is for 6mm ARC or 6.5 Grendel and also anneal every firing. I don't loose cases to split necks even if the case head has Starline stamped on it.

Sounds like we went through a similar experience and landed on a similar process. I also thought of the pass-though idea while trying to rehabilitate hundreds of cases that were unusable after being fired in a Satern barrel with a loose chamber and a giant chamber entry chamfer.

I agree with all your points. Pass-through sizing likely isn't needed for bolt guns or ARs with tight chambers, but at this point I have a best practice and I'm sticking to it. Using a sizing die that leaves the brass just under the maximum diameter also gives you a lot more leeway, as does using brass designed to withstand pressure below the AR unsupported chamber region.

Unfortunately my Lapua/AA brass doesn't appear to have a heavier support area near the base. Lapua 6.5 Grendel cases were one of the original "belted case" cases in 6 ARC. I do not have the belted case issue with my converted Lapua cases, but they will swell some down low. My Wilson FL bushing die will get that out though. Now that I have more or less settled on loads, I am more gentle on my cases.

I will say Lapua is a SOB running through the Sgt of Arms die used as a pass through. A great lube is mandatory!

I will say Lapua is a SOB running through the Sgt of Arms die used as a pass through. A great lube is mandatory!

Load Data has some fairly decent data but you have to be a member.Has anyone tried loading Nosler RDF 105gr projectiles? I've been trying to find load data for anything NOT Hornady and cannot seem to find anything. Same for Berger 108gr projectiles.

Look at Hodgden's website, they have some also.Load Data has some fairly decent data but you have to be a member.

Look at Hodgden's website, they have some also.

So looking at the hodgdon site and the Nosler RDF 105gr projectile, Do you go low and look at the 103gr or high and look at the 107gr since they dont show any data for a 105?

Just pick one and do some testing. You’re splitting hairs.So looking at the hodgdon site and the Nosler RDF 105gr projectile, Do you go low and look at the 103gr or high and look at the 107gr since they dont show any data for a 105?

Agree.Just pick one and do some testing. You’re splitting hairs.

You can split hairs further by using starting data from the bullet with a similar bearing surface. That is getting deep in the weeds.

With just about any cartridge I have worked up loads for (a pile of them), I start off in the middle of a listed range. I have never found accuracy or consistency at the bottom.

16”?Dusted off the craddock 6 arc and finally shot some 105 hybrids with varget and alpha brass. Only 5 shot groups at 125 yards but 27grs was .6 with a sd of 5.8. Going to explore this area. Average was 2456 fps.

Bought a Noveske 18'' and all factory hornady was high 2500s and low 2600s. Ive been using TAC to get the speed but finally ran out of this BS powder, Going to try N135 and N140 next unless i run into a stash of H4895 or XBR8208

Im about to work up some loads with these exact same 3 powders for my 18”N140 next unless i run into a stash of H4895 or XBR8208

Post results, im real curious about those, id suspect if you push to pressure N140 should have the best speeds but i dont think ive ever shot 8208 an it not one hole them in a given cartridge. I currently have some N150 I might end up trying just for science purposes. I have found a few places that have 8208 local to me but they are around $60 a #. I have been toying with the idea of getting some of the 80gr eld-vt and loading them up with H335 just to see what happens.Im about to work up some loads with these exact same 3 powders for my 18"

Will do!Post results, im real curious about those, id suspect if you push to pressure N140 should have the best speeds but i dont think ive ever shot 8208 an it not one hole them in a given cartridge. I currently have some N150 I might end up trying just for science purposes. I have found a few places that have 8208 local to me but they are around $60 a #. I have been toying with the idea of getting some of the 80gr eld-vt and loading them up with H335 just to see what happens.

Dusted off the craddock 6 arc and finally shot some 105 hybrids with varget and alpha brass. Only 5 shot groups at 125 yards but 27grs was .6 with a sd of 5.8. Going to explore this area. Average was 2456 fps.

Anybody running 15 inch hand guards and the gas block is contacting the inside of a hand guard when tapping it and I’m assuming when the gun shoots the barrel flex enough too… makes then”ting” or “thing”. Or “ thunk” sound when tapping the hand guard. It is a .875 so it’s the longer barrels whether I use clamp or bottom to bolt style adjustable gas blocks. They both hit with the same amount of flex.

I assume yours is the 0.75 gas block being inside Noveski 18 inch?

Last edited:

if gun was built

if gun was built with quality parts and youre not loading insanely into a bipod while that happens idk. Barrels that have a .875 and .930 gb ive always bought the oversized aero handguards due to the giant ID in the rail. For most everything else i use geiselle.Anybody running 15 inch hand guards and the gas block is contacting the inside of a hand guard when tapping it and I’m assuming when the gun shoots the barrel flex enough too… makes then”ting” or “thing”. Or “ thunk” sound when tapping the hand guard. It is a .875 so it’s the longer barrels whether I use clamp or bottom to bolt style adjustable gas blocks. They both hit with the same amount of flex.

I assume yours is the 0.75 gas block being inside Noveski 18 inch?

One of my 20 practical has a 24".875 gas block under a 15" handgaurd. I used the Aero adjustable gas block. It also has an ar stoner billet receiver which actually seems to be pretty stiff when trying to flex the handgaurd and make it contact the block.

using quality parts .. Tried both versions of the gas blocks I thought for sure I had figured it out when I had to clamp on version from JP, but that made clearance on the sides, instead of the bottom-just. As tightif gun was built

if gun was built with quality parts and youre not loading insanely into a bipod while that happens idk. Barrels that have a .875 and .930 gb ive always bought the oversized aero handguards due to the giant ID in the rail. For most everything else i use geiselle.

Perhaps I just need to torque it to the 40 that it says I believe it is written on the hand guard and see what it ends up doing..

Contemplated just cutting the end part off that I needed, but would pretty much make a handguard resale useless

Attachments

I had this issue when I ran a fatter OdinWorks 20" 6.5 Grendel barrel in a BCM MCMR 15" handguard, gas block had very slight clearance that was gobbled up in handguard flex under bipod load. The guys at Ridgeline mentioned this about the BCM handguards when I was there a couple years back, the flexy part.Anybody running 15 inch hand guards and the gas block is contacting the inside of a hand guard when tapping it and I’m assuming when the gun shoots the barrel flex enough too… makes then”ting” or “thing”. Or “ thunk” sound when tapping the hand guard. It is a .875 so it’s the longer barrels whether I use clamp or bottom to bolt style adjustable gas blocks. They both hit with the same amount of flex.

I assume yours is the 0.75 gas block being inside Noveski 18 inch?

Gas block clearance is snug on some handguards on the market. I fixed the OdinWorks 20" with an Aero Precision Enhanced upper receiver & handguard with lots of interior room in the tube. A slimmer profile gas block might have helped a tiny bit but on a fatter barrel with fat gas block journal your handguard options will need to be the fatter tubes.

using quality parts .. Tried both versions of the gas blocks I thought for sure I had figured it out when I had to clamp on version from JP, but that made clearance on the sides, instead of the bottom-just. As tight

Perhaps I just need to torque it to the 40 that it says I believe it is written on the hand guard and see what it ends up doing..

Contemplated just cutting the end part off that I needed, but would pretty much make a handguard resale useless

This is where using specific handguards with larger ID's is required. SLR and Seekins make a few. Specifically clearing SLA AGB with enough room to not hit, even up to 0.936 gas blocks

If theyll take that handguard back id swap if for the one with larger ID.using quality parts .. Tried both versions of the gas blocks I thought for sure I had figured it out when I had to clamp on version from JP, but that made clearance on the sides, instead of the bottom-just. As tight

Perhaps I just need to torque it to the 40 that it says I believe it is written on the hand guard and see what it ends up doing..

Contemplated just cutting the end part off that I needed, but would pretty much make a handguard resale useless

Just got in 500 80gr eldvt bullets and going to try then in my 18” proof cf barrel. Hornady data shows 3000fps with benchmark in an 18” barrel which seems pretty optimistic to me but if I get close to that it would be a great varmint/target round inside of 600 yards. Anyone have any suggestions on seating depth for the eldvt?

I think the 18" proofs are rifle +1" right? Did you happen to measure the gas port size on yours? I'm curious if it's greater than or less than 0.100"Just got in 500 80gr eldvt bullets and going to try then in my 18” proof cf barrel. Hornady data shows 3000fps with benchmark in an 18” barrel which seems pretty optimistic to me but if I get close to that it would be a great varmint/target round inside of 600 yards. Anyone have any suggestions on seating depth for the eldvt?

I have a 18" rifle +2 barrel (0.093" port) and I'm trying to get a feel for different gas port sizes for different length gas systems/dwell times for 6 ARC.

Edit: never mind, just found it on their website:

If you have a COAL tool (from Hornady) to start, I'd set my COAL at minus .020" from where it touches the lands, so long as it still fits in the magazine, and go from there. The 3000 fps with 18" barrel is pretty optimistic, in a 24" barrel, yes.Just got in 500 80gr eldvt bullets and going to try then in my 18” proof cf barrel. Hornady data shows 3000fps with benchmark in an 18” barrel which seems pretty optimistic to me but if I get close to that it would be a great varmint/target round inside of 600 yards. Anyone have any suggestions on seating depth for the eldvt?

Handloading will get you close. The factory eldvt already goes around 2800 out of a 18 inch. My Handloads were going around 2940-2970 with tac and CFE. They were at like 2859 with varget and really accurate so if he’s got alpha brass I’m sure he can easily get 3000If you have a COAL tool (from Hornady) to start, I'd set my COAL at minus .020" from where it touches the lands, so long as it still fits in the magazine, and go from there. The 3000 fps with 18" barrel is pretty optimistic, in a 24" barrel, yes.

Results were pretty disappointing as usual with my proof barrel. Got up to 2860 fps with great sd/es on almost every powder charge but mediocre accuracy. This proof barrel doesn’t seem to like any bullet I try except the 58gr vmax. It shoots those into tiny groups. I’m going to try the 80s in my craddock barrel next. The craddock barrel hasn’t been hard to find a load for at all but the proof barrel sucks. Might have to send it back.

in my limited experience, proofs seem to be like the CRBs in the fact that you constantly have to clean them/strip the copper out for them to continue to shoot well.Results were pretty disappointing as usual with my proof barrel. Got up to 2860 fps with great sd/es on almost every powder charge but mediocre accuracy. This proof barrel doesn’t seem to like any bullet I try except the 58gr vmax. It shoots those into tiny groups. I’m going to try the 80s in my craddock barrel next. The craddock barrel hasn’t been hard to find a load for at all but the proof barrel sucks. Might have to send it back.

Seems a bit odd, I don't have any accuracy issues with my Proof barrels (3 going right now). They almost always get pretty rave reviews. I don't clean barrels, and haven't seen any accuracy loss.in my limited experience, proofs seem to be like the CRBs in the fact that you constantly have to clean them/strip the copper out for them to continue to shoot well.

Depends on your firing schedule, Im at 1200 rounds in about 3-4 months. Was using some pretty shitty powder. For me i could go 200-300ish rounds before groups would go from .8s to 1.5sSeems a bit odd, I don't have any accuracy issues with my Proof barrels (3 going right now). They almost always get pretty rave reviews. I don't clean barrels, and haven't seen any accuracy loss.

All my other proof barrels shoot great but this 6 arc barrel is starting to get on my nerves.Seems a bit odd, I don't have any accuracy issues with my Proof barrels (3 going right now). They almost always get pretty rave reviews. I don't clean barrels, and haven't seen any accuracy loss.

Have you tried picking a specific bullet for your use case like a 103gr eld-x or 95gr SMK, etc. then try a few different powders for that particular bullet (8208 vs N140 vs H4895)? Sometimes the barrel likes a particular powder for a particular bullet and the only way to find out is to try a few different powders.All my other proof barrels shoot great but this 6 arc barrel is starting to get on my nerves.

For example, if you're testing 3 powders for one bullet a good test to do is set up 3 points of aim (one for each powder) then load up a 10-15 charge ladder test with one shot for each charge weight (for 6 arc I go in 0.1gr increments) then look at overall group size between the 3 powders. The one with the smallest group is your best match for that bullet/barrel combo.

It would look something like below (powder C is best/least fussy match for the bullet/barrel):

Then you can do a bunch of more refined tests for charge weight/COAL once you zero in on your powder to find the specs that produce the least amount of change to your point of impact as your charge weights go up/down in the ladder test

Yes I have tried multiple bullets with multiple powders. I’m not new to reloading. I normally pick a bullet and a powder that I want to use and find an accurate load. This barrel might just be a turd but I’m not the type to give up very quickly without trying a lot of options. I cant get it to shoot 105 hybrids with varget and alpha brass so it’s probably a turd.Have you tried picking a specific bullet for your use case like a 103gr eld-x or 95gr SMK, etc. then try a few different powders for that particular bullet (8208 vs N140 vs H4895)? Sometimes the barrel likes a particular powder for a particular bullet and the only way to find out is to try a few different powders.

For example, if you're testing 3 powders for one bullet a good test to do is set up 3 points of aim (one for each powder) then load up a 10-15 charge ladder test with one shot for each charge weight (for 6 arc I go in 0.1gr increments) then look at overall group size between the 3 powders. The one with the smallest group is your best match for that bullet/barrel combo.

It would look something like below (powder C is best/least fussy match for the bullet/barrel):

Then you can do a bunch of more refined tests for charge weight/COAL once you zero in on your powder to find the specs that produce the least amount of change to your point of impact as your charge weights go up/down in the ladder test

What was the amount of brass growth on your first firing? I’m measuring 10,000s of a inch when I compare a new case to a 1x fired case just as an FYI I think this is a generous chamber but case must be resized 2-thousands of shoulder bump in order for me to be able to chamber the brass after being shotMy 6ARC experience is solely in AR15s using Starline and Hornady brass....

That being said, I have experienced the "belting" issue that you mention using both Starline and Hornady brass when I was using a RCBS Small Base sizing die. After a few hundred rounds, I decided to buy a Lee sizing die and the issue completely disappeared. I have read that many others have had the same experience.

Another brass related issue I have noticed is split necks. My Starline brass started to have splits around the 3rd firing....1 out of 100 cases I estimate. On the 4th firing, it was about 5 per 100.

I look forward to seeing your firing results from the Alpha brass. I just need to have a few too many beers one night so I can motivate myself to order some!

I messed around with what was supposed to be a quality 6 arc barrel. I never could get it shoot. I had a bunch of other problems also.Yes I have tried multiple bullets with multiple powders. I’m not new to reloading. I normally pick a bullet and a powder that I want to use and find an accurate load. This barrel might just be a turd but I’m not the type to give up very quickly without trying a lot of options. I cant get it to shoot 105 hybrids with varget and alpha brass so it’s probably a turd.

Then I picked up a cheap cmmg 6 arc barrel, while I was waiting for an x-caliber 6 arc barrel, having washed my hands cometeley of the company with the trouble barrel. The cmmg shooots pretty good for a 16" .750 profile barrel, and the x-caliber shoots quite well. It is a 22"+2 gas spr profile.

too late, I already went at it with a Dremel…If theyll take that handguard back id swap if for the one with larger ID.

I seem to have got enough room on the edges anyway, and the important area is without compromising integrity.

it looks to be enough room now… with the barrel favoring the right side gas block was making contact with the handguard entire time. I would think that would absolutely fowl up harmonics.

Now it’s got quite a bit of space and the hand guard has to be hit from the side to make contact with the gas block.

Last edited:

Heads up re: shooting heavies if you haven’t discovered it yourself already. I was shooting some 109’s in alpha brass at 2.260” and they chamber ok but not ideal, they are so pointy that the tip sometimes gets caught up in the area below the feed ramps. Better to try and go down a little more to 2.252ish to allow some wiggle room if the powder charge allows it.

What company made such a shitty 6arc barrel that you gave up on them completely? We should know who to avoid.I messed around with what was supposed to be a quality 6 arc barrel. I never could get it shoot. I had a bunch of other problems also.

Then I picked up a cheap cmmg 6 arc barrel, while I was waiting for an x-caliber 6 arc barrel, having washed my hands cometeley of the company with the trouble barrel. The cmmg shooots pretty good for a 16" .750 profile barrel, and the x-caliber shoots quite well. It is a 22"+2 gas spr profile.

Last edited:

Rainier UM Gold extensions are trash. They replaced my first barrel after it set back the lugs in the extension .015 in 200 rounds. Second barrel with same shit extension has already set back lugs .006 in 100 rounds so I pulled it. Fuck them, I told them what the problem was the first time. They did nothing different.What company made such a shitty 6arc barrel that you gave up on them completely? We should know who to avoid.

I have a 22” Craddock RTR setting on the bench.

That does make sense that the enhance version upper would have more clearance.. talking to some of the guys at the shop they did not advise me at getting a suppressor compatible hand guard as they’re pretty darn bigI had this issue when I ran a fatter OdinWorks 20" 6.5 Grendel barrel in a BCM MCMR 15" handguard, gas block had very slight clearance that was gobbled up in handguard flex under bipod load. The guys at Ridgeline mentioned this about the BCM handguards when I was there a couple years back, the flexy part.

Gas block clearance is snug on some handguards on the market. I fixed the OdinWorks 20" with an Aero Precision Enhanced upper receiver & handguard with lots of interior room in the tube. A slimmer profile gas block might have helped a tiny bit but on a fatter barrel with fat gas block journal your handguard options will need to be the fatter tubes.

got a new PWS 6 arc upper with 1:7.5 18” bbl. I’m waiting on my TOMB for my suppressor but I got bored and loaded up some 107 smks in Hornady brass, CCI 450, 28.6 Cfe223, at 2.255” coal. Just a smidge of pressure but over all they shot great. At 300 yards I was dinging a 6” plate I the same spot for about 10 shots. Will lower accordingly for my suppressor but I’m super impressed with the PWS Mk118.

Similar threads

- Replies

- 65

- Views

- 9K

- Replies

- 9

- Views

- 395