My buddy just reloaded some 380's. He used once fired brass, resized and loaded 3.4gr 231(max load)and a slight roll crimp. The fired brass has a doughnut not quite half way from the bullet end of the case. If I put a fired case into the chamber it stops with about 1/4 inch sticking out. I told him to stop. Sounds like to hot a load but I have never seen a doughnut midway on a pistol case. Is this how too hot a load shows on pistol brass?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

380 brass doughnut

- Thread starter Derek01

- Start date

Re: 380 brass doughnut

Could be several things. What pistol? Is it cam locked or pure blow back? Section the brass. Is the front half thinner than the rear? Can you see the doughnut from outside of the case, or is it a case manufacture item? It could be that the manufacturer made the rear thick and the front end thinner for strength purposes...also it could be an internal step to prevent the bullet from being seated deeper upon chambering.

Could be several things. What pistol? Is it cam locked or pure blow back? Section the brass. Is the front half thinner than the rear? Can you see the doughnut from outside of the case, or is it a case manufacture item? It could be that the manufacturer made the rear thick and the front end thinner for strength purposes...also it could be an internal step to prevent the bullet from being seated deeper upon chambering.

Re: 380 brass doughnut

being a .380,I think don't need it a roll crimp,but a slight TAPER crimp_ seems you have some bulged case (not a donut,for sure)_a bulged case is the consequence of a too much hot load,and a roll crimp is perfect to make a hot load even hotter_stop,please_read some reloading manual,control if you have the correct .380 dies, and don't start from the max!

being a .380,I think don't need it a roll crimp,but a slight TAPER crimp_ seems you have some bulged case (not a donut,for sure)_a bulged case is the consequence of a too much hot load,and a roll crimp is perfect to make a hot load even hotter_stop,please_read some reloading manual,control if you have the correct .380 dies, and don't start from the max!

Re: 380 brass doughnut

The pistol is a Taurus PT-58. Sorry the crimp was a slight taper crimp not roll crimp. He was working up loads because the feet per sec was so low. I told him to stop and perhaps try another powder to see if he can get faster speed without higher pressure. He does start low and work up. Just that neither of us has seen buldged cases like that before. Thanks for helping

The pistol is a Taurus PT-58. Sorry the crimp was a slight taper crimp not roll crimp. He was working up loads because the feet per sec was so low. I told him to stop and perhaps try another powder to see if he can get faster speed without higher pressure. He does start low and work up. Just that neither of us has seen buldged cases like that before. Thanks for helping

Re: 380 brass doughnut

Pics would really be nice.Now with that said your load might be OK I load for a P238 useing HP38( same as 231 ) @ 3.4gn with a 88gn or 90gn bullet.Now my over all length for both are .965 but you never said your over all length.I too put a slight tapper crimp on my loads.So I think if all was done RIGHT the load is OK to fire.When I tested my loads it not only fired in my P238 but it all so fired in a full size Bersa with out any kind of problems or pressure.

OK I just reread your post like 4 times.If I am reading it right you said that a fired case will not go into the chamber all the way.This should be right because of it being a fired case.I ask you if a reloaded bullet ( or resized case ) will go into the chamber like it should.If not then something is wrong.You did say that he was useing ounce fired cases to load with.

So to check behind him try putting a resized case into the chamber to see if he has the die set to resize the case like it should be.I would even check to see that if he has the rest of the dies set to do as they should all so.The bell die/powder through die should be set to bell the case just enough to allow a bullet to just start being seated by hand.

Pics would really be nice.Now with that said your load might be OK I load for a P238 useing HP38( same as 231 ) @ 3.4gn with a 88gn or 90gn bullet.Now my over all length for both are .965 but you never said your over all length.I too put a slight tapper crimp on my loads.So I think if all was done RIGHT the load is OK to fire.When I tested my loads it not only fired in my P238 but it all so fired in a full size Bersa with out any kind of problems or pressure.

OK I just reread your post like 4 times.If I am reading it right you said that a fired case will not go into the chamber all the way.This should be right because of it being a fired case.I ask you if a reloaded bullet ( or resized case ) will go into the chamber like it should.If not then something is wrong.You did say that he was useing ounce fired cases to load with.

So to check behind him try putting a resized case into the chamber to see if he has the die set to resize the case like it should be.I would even check to see that if he has the rest of the dies set to do as they should all so.The bell die/powder through die should be set to bell the case just enough to allow a bullet to just start being seated by hand.

Re: 380 brass doughnut

Funny you posted before I did.Yeah he sounds like he is on the right track after reading your last post.For me with my P238 I have been chaseing the FPS thing myself.the only way I could do it was to add .2 more grains to my load.I will add that its as fare I can go with my pistol with HP 38.I too have post in many places trying to get help but yet found any to my liking.

The only other thing I have found to work for me is that I tried a 88gn Remington HP bullet with 3.7gn HP-38.When I tested it in a watter jug test it gave me a better mushroom from 15 feet than a 90gn XTP did.My next bullet of choice when I run out of the 88gn bullets will be a 90gn Seirra HP.I have yet to find a powder to fit the bill even playing around on QL.

Funny you posted before I did.Yeah he sounds like he is on the right track after reading your last post.For me with my P238 I have been chaseing the FPS thing myself.the only way I could do it was to add .2 more grains to my load.I will add that its as fare I can go with my pistol with HP 38.I too have post in many places trying to get help but yet found any to my liking.

The only other thing I have found to work for me is that I tried a 88gn Remington HP bullet with 3.7gn HP-38.When I tested it in a watter jug test it gave me a better mushroom from 15 feet than a 90gn XTP did.My next bullet of choice when I run out of the 88gn bullets will be a 90gn Seirra HP.I have yet to find a powder to fit the bill even playing around on QL.

Re: 380 brass doughnut

380 brass has a .175" thick web. Further than that from the base is thin case wall.

I have overload worked up 380s.

I would put them in 3 categories:

a) Get case bulges at 10% more powder than published loads.

Feed ramp intrusion is .270 ~ .290"

The Kel-tec P3AT and Ruger LCP are the only pistols in this category.

b) Get case bulges at 100% more powder than published loads.

Feed ramp intrusion ~ .215"

c) Do not get case bulges at 200% extra powder.

Feed ramp intrusion .175" or less.

One pistol bulged a .095" thick chamber wall [barrel, not the case] with a triple load.

The blow backs do better than the locked breech, as they are older and heavier designs.

What can you do?

Take the 380 barrel out of the pistol.

Put piece of brass in your barrel.

Trace the outline of the feed ramp on the brass with a needle.

Measure the distance from the base of the case to the line.

That is the barrel's feed ramp intrusion.

If you were an advanced reloader working up to a case bulge, you might notice that the bulge is .010"~ .020" different from the needle measurement. That error is increased by headspace minus case length and decreased by inside bend radius offset.

380 brass has a .175" thick web. Further than that from the base is thin case wall.

I have overload worked up 380s.

I would put them in 3 categories:

a) Get case bulges at 10% more powder than published loads.

Feed ramp intrusion is .270 ~ .290"

The Kel-tec P3AT and Ruger LCP are the only pistols in this category.

b) Get case bulges at 100% more powder than published loads.

Feed ramp intrusion ~ .215"

c) Do not get case bulges at 200% extra powder.

Feed ramp intrusion .175" or less.

One pistol bulged a .095" thick chamber wall [barrel, not the case] with a triple load.

The blow backs do better than the locked breech, as they are older and heavier designs.

What can you do?

Take the 380 barrel out of the pistol.

Put piece of brass in your barrel.

Trace the outline of the feed ramp on the brass with a needle.

Measure the distance from the base of the case to the line.

That is the barrel's feed ramp intrusion.

If you were an advanced reloader working up to a case bulge, you might notice that the bulge is .010"~ .020" different from the needle measurement. That error is increased by headspace minus case length and decreased by inside bend radius offset.

Re: 380 brass doughnut

My friends shooting a 95 gr bullet at 0.984" His reloading book says 3.4gr of 231 is max. Hodgdon online says 3.2. the buldge is only one one side so it could be from the feed ramp. I will post photos of the case tonight when I can get a few from him. Thanks again

My friends shooting a 95 gr bullet at 0.984" His reloading book says 3.4gr of 231 is max. Hodgdon online says 3.2. the buldge is only one one side so it could be from the feed ramp. I will post photos of the case tonight when I can get a few from him. Thanks again

Re: 380 brass doughnut

The marks on many semi auto case heads will be an ejector mark at 9 O'Clock and an extractor mark at 3 O'Clock. Case bulges are rare, but if they are there, they will be at 6 O' Clock.

Beretta 1934 380s are different, with the extractor on top.

The marks on many semi auto case heads will be an ejector mark at 9 O'Clock and an extractor mark at 3 O'Clock. Case bulges are rare, but if they are there, they will be at 6 O' Clock.

Beretta 1934 380s are different, with the extractor on top.

Re: 380 brass doughnut

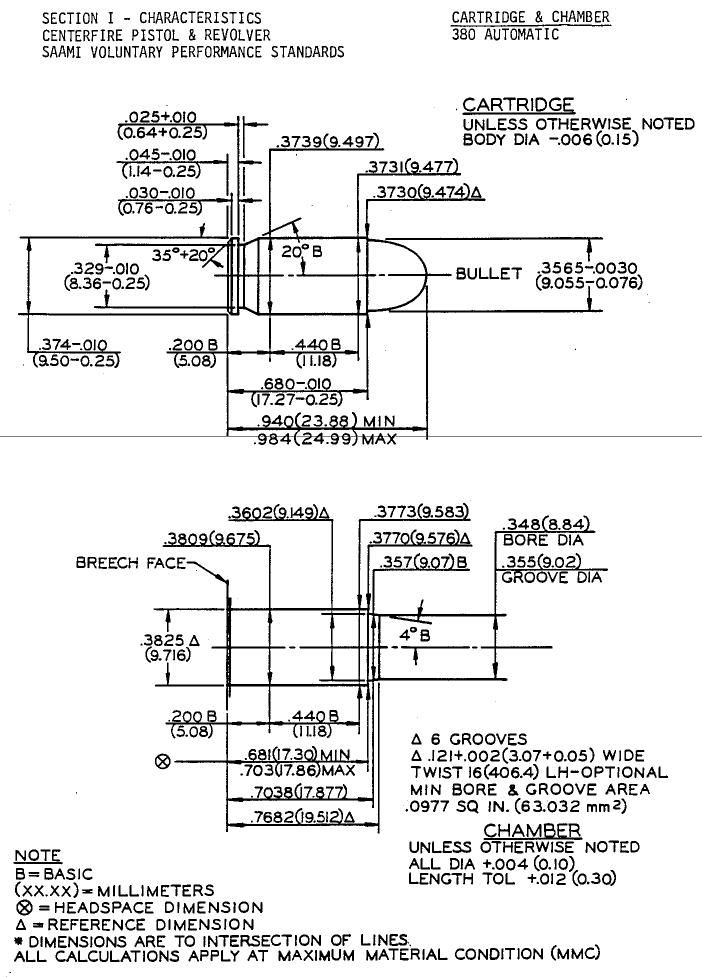

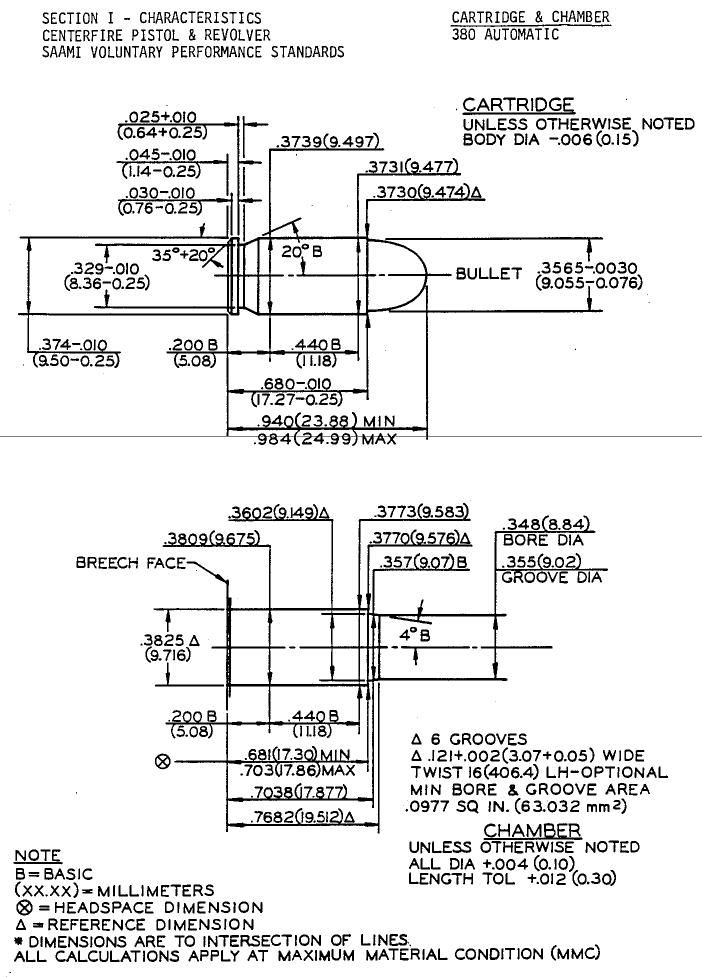

Here is a pic of a bulged case with 380 +P level loading in very poor case support chamber ~ .270" feed ramp intrusion.

The OP bulge is even further from the case head.

What the OP has is a large diameter chamber.

The SAAMI range for chambers is from .388" to .392" where that bulge occurs.

If you can measure the diameter at that bulge accurately, and it is greater than .392", then the problem is the chamber.

Better still would be if you could measure the chamber, but that is harder to do.

Here is a pic of a bulged case with 380 +P level loading in very poor case support chamber ~ .270" feed ramp intrusion.

The OP bulge is even further from the case head.

What the OP has is a large diameter chamber.

The SAAMI range for chambers is from .388" to .392" where that bulge occurs.

If you can measure the diameter at that bulge accurately, and it is greater than .392", then the problem is the chamber.

Better still would be if you could measure the chamber, but that is harder to do.

Re: 380 brass doughnut

Your brass is hot loaded and is ejected from a barrel that is not fully supported, or simply Glocked, the fix is to down load a little, and run the brass thru a Lee Buldge Buster or Redding GRX, the LBB is cheaper and does exactly the same thing.

Your brass is hot loaded and is ejected from a barrel that is not fully supported, or simply Glocked, the fix is to down load a little, and run the brass thru a Lee Buldge Buster or Redding GRX, the LBB is cheaper and does exactly the same thing.