but thought, what the heck, accuracy should be better, dont think it'll hurt anything, Tubb says he's convinced.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Don't get your hopes up.....but it will make your gun heavier

but thought, what the heck, accuracy should be better, dont think it'll hurt anything, Tubb says he's convinced.

At least a hundred times. You guys from the south can talk, maybe you didnt notice what state Im from, we have this white stuff up here, they call it snow, ever hear of it? The range closes the day before deer hunting season and dont reopen til May 1st, gimme a break, ever shoot when your fingers cant feel the trigger? Its 26 fricken degrees right now!! Yeah, the recoil lug, thats for the rebarrel Im having Chad do.

You're not going to get out of it that easy! I went to school in South Dakota and shot all winter, every winter. Can't imagine you're snowed in for the entire time. Time to find a new place to shoot!

Don't get your hopes up.....but it will make your gun heavier

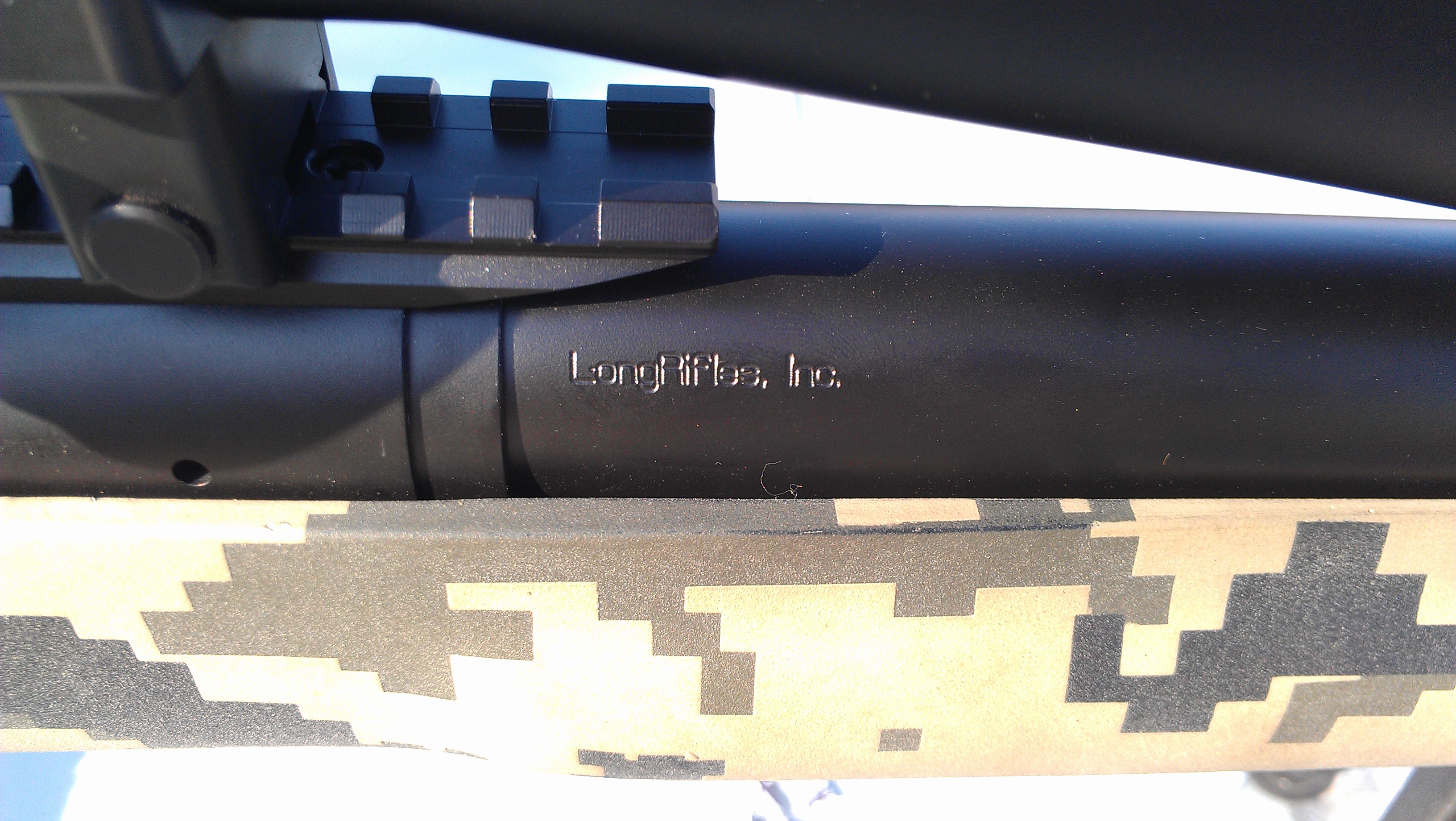

This is something I've wondered about. I'd like to know more about this. From the pictures it looks like the actions with integral recoil lugs have a smaller lug contact surface. Does this make a difference in the longevity of the recoil surface on the stock or the performance of the rifle?A broader footprint (spreading the load over a larger surface) seems to make more sense and this is where I personally feel the aftermarket lugs out perform the factory ones.

i prefer a thicker lug because it gives a bit more "breathing room" when threading up to the shoulder, not because chicks dig it or because i feel it makes the rifle any more accurate.

This is something I've wondered about. I'd like to know more about this. From the pictures it looks like the actions with integral recoil lugs have a smaller lug contact surface. Does this make a difference in the longevity of the recoil surface on the stock or the performance of the rifle?