Precision loading on the 650 will depend more on what powder you want to use than anything.

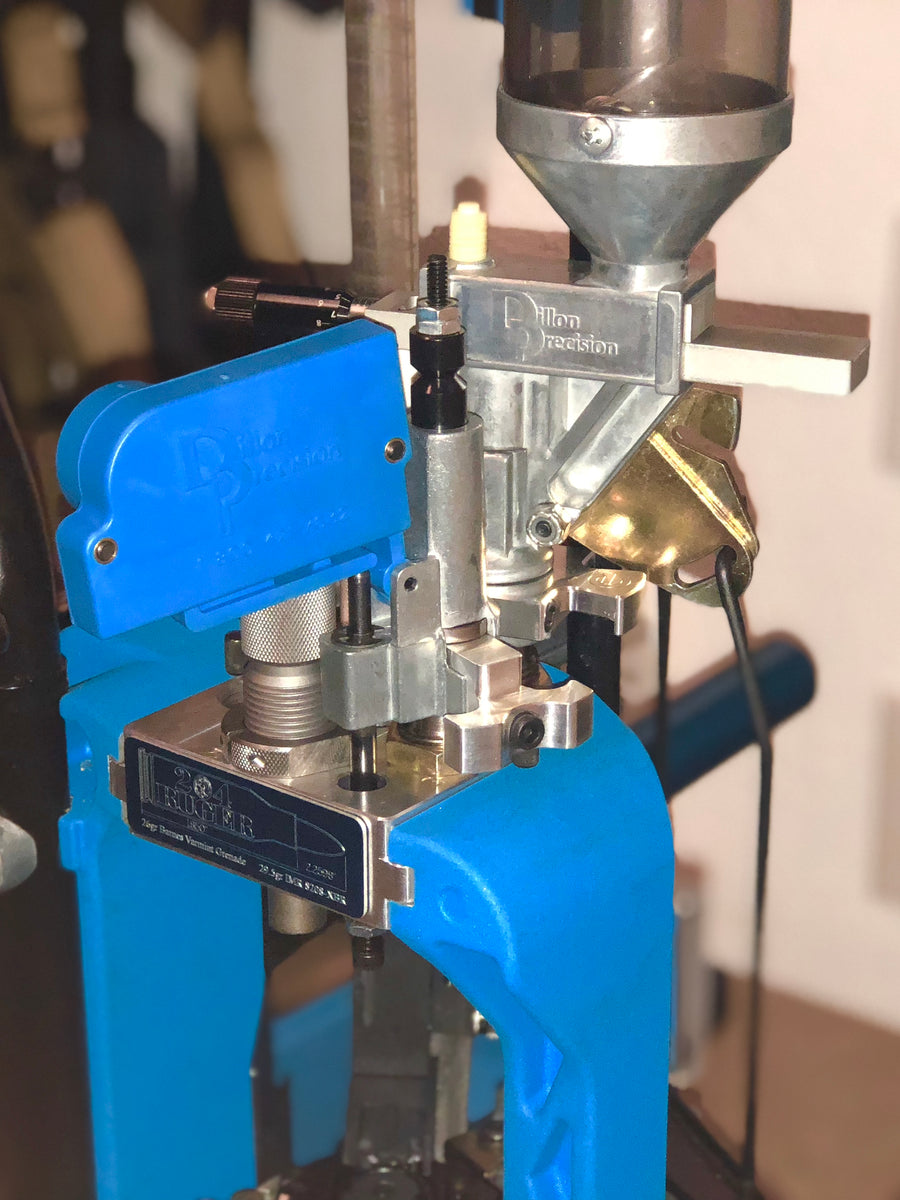

Only if your using the Dillon powder dispenser... A bunch of us use the Dillon powder die without the dispenser and a funnel to drop powder like Varget, H4350 and the like. I recently worked with Area 419 to have an adapter made that fits the Dillon powder die with their aluminum milled funnel which is what Im using now. You can buy it directly from Area419.