A job came in that had what most would consider an ambitious timeline. Take a new-in-the-box M700 and build a tuned up barreled action from it in 2 days. Not impossible, but your going to be hustling. Due to be ready by CoB today. We open at 8am and close at 4pm. Mtn time.

Now, complicate it. Was out of receivers and they were a day late due to a winter storm. We started at 10:30am this morning. In addition to the blueprinted receiver/bolt, barrel installation, add the following electives:

How long? Pick a number. Would the deadline get met? You decide.

We just did all of this. 3 hours, 37 minutes. Start to #14. I've not called the client yet.

So, here we go:

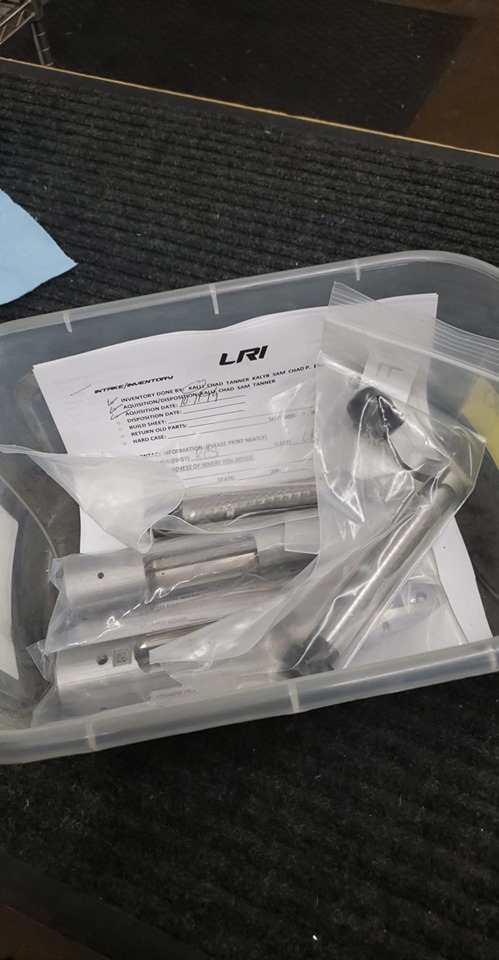

1. Intake/Log in.

2. Hone receiver:

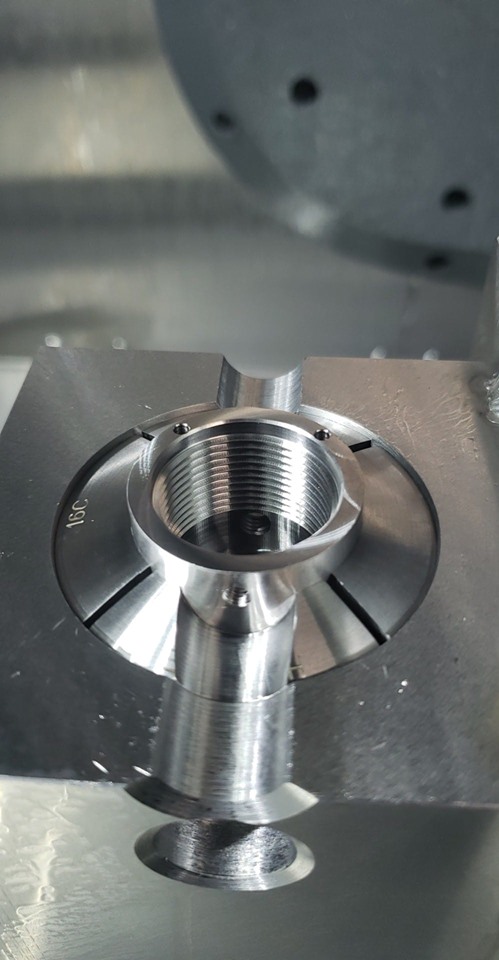

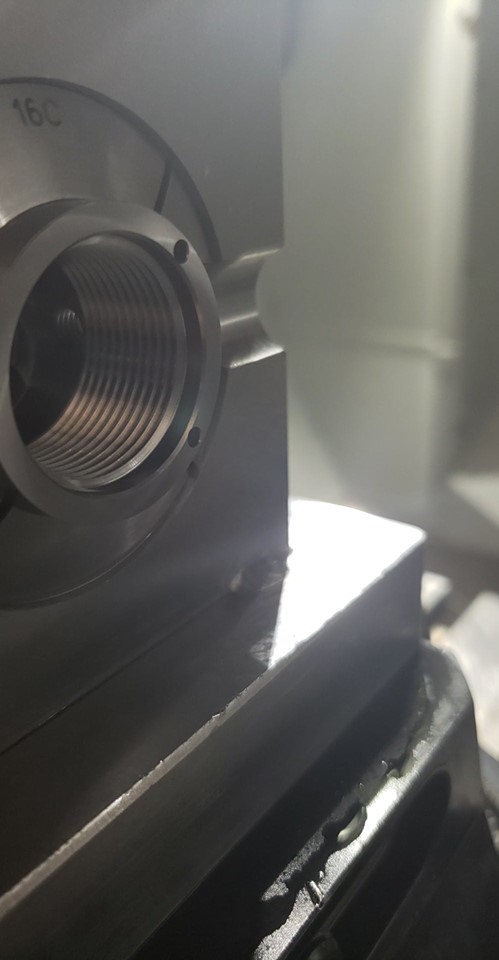

3. Setup and machine in 5 axis.

3a. Machine ring face

3b. ID bore

3c. Thread mill to 1.085-16

3d. Chamfer ring face

3e. Higbee cut lead thread

3f. Drill for pinned recoil lug

3g. ID bore base holes for 8-40's

3h. ID thread mill base holes to 8-40

3i. Machine for Side Bolt Release

Simultaneous to this being done:

4. Blueprint bolt head

4a. Probe and square the face

4b. Square the lugs

4c. Square the nose

4d. ID thread mill bolt nose for M16xtr bushing

4e. Thread on bushing and solder

4f. Finish machine bolt nose/bushing

4g. Drill for 2nd ejector pin

4h. Machine for M16 Xtr slot

4i. Machine for striker bushing installation

4j. Turn striker pin to .0625"

4k. Flute bolt body

Next page/post (whatever, lol)

Now, complicate it. Was out of receivers and they were a day late due to a winter storm. We started at 10:30am this morning. In addition to the blueprinted receiver/bolt, barrel installation, add the following electives:

- Time/Tig/solder

- 8-40 base holes

- Pinned lug

- Bolt fluting

- Tac knob

- M16xtr install

- dual ejectors

- Bush the firing pin and turn to 1/16"

- Thread the muzzle

- Fit a thread protector

- Engrave it

- Spin polish it, t

- Side Bolt Release installation

- Test fire

- Call client to tell him its done.

How long? Pick a number. Would the deadline get met? You decide.

We just did all of this. 3 hours, 37 minutes. Start to #14. I've not called the client yet.

So, here we go:

1. Intake/Log in.

2. Hone receiver:

3. Setup and machine in 5 axis.

3a. Machine ring face

3b. ID bore

3c. Thread mill to 1.085-16

3d. Chamfer ring face

3e. Higbee cut lead thread

3f. Drill for pinned recoil lug

3g. ID bore base holes for 8-40's

3h. ID thread mill base holes to 8-40

3i. Machine for Side Bolt Release

Simultaneous to this being done:

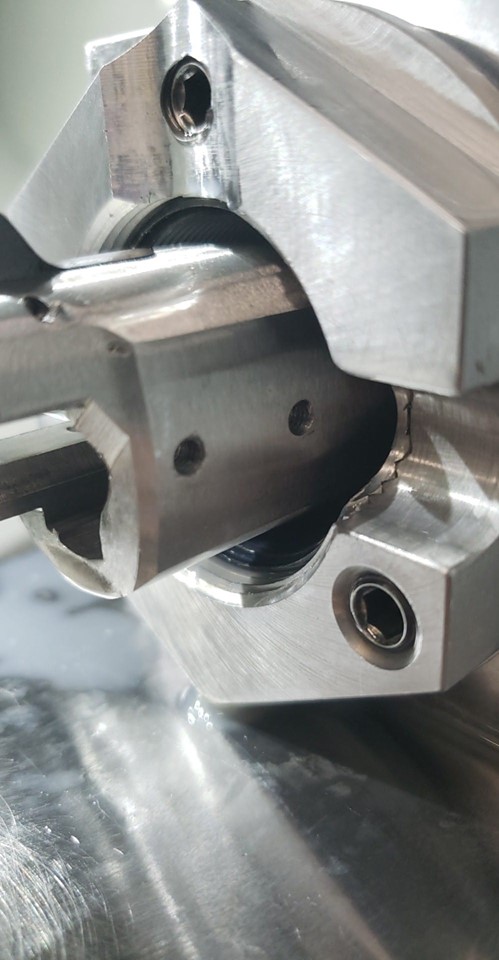

4. Blueprint bolt head

4a. Probe and square the face

4b. Square the lugs

4c. Square the nose

4d. ID thread mill bolt nose for M16xtr bushing

4e. Thread on bushing and solder

4f. Finish machine bolt nose/bushing

4g. Drill for 2nd ejector pin

4h. Machine for M16 Xtr slot

4i. Machine for striker bushing installation

4j. Turn striker pin to .0625"

4k. Flute bolt body

Next page/post (whatever, lol)