Hey fellas,

I have been wanting to add some weight to my .308 to help with stability, recoil, etc. I looked at the MDT weight kits but at $60 per .78lbs they are out of my budget. I'm not sure what MDT makes their weights out of, but at that price it must be something fairly exotic. I don't see a need for that, so sketched this up and cobbled it together out of A36. It's about $20 worth of steel and $20 worth of hardware.

Design Insights:

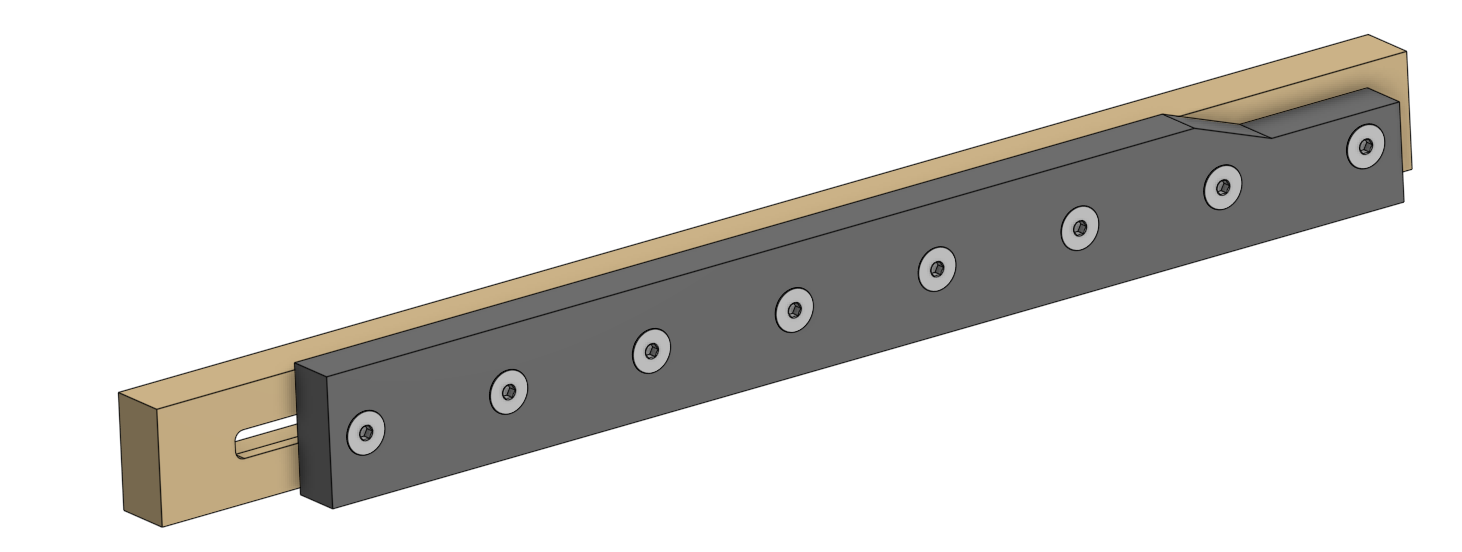

I wanted to add 4lb's to the rifle, move the CG slightly rearward, and also try to stiffen the forend if possible. The arca rail should not be obstructed, but adding surface area to the bottom of the forend is desirable. As such, the weights should be mounted as low as possible without obstructing the arca rail.

Because each weight is about 2 lbs I had some concerns about the weights sliding around under recoil. The MDT weights have lugs that interface with the M-Lok slots. I don't have a mill, so I was having a hard time deciding how to do this. In the end I decided to place a few 8-32 socket head cap screws on the back side which are aligned with the front wall of an M-lok slot. Each weight is attached by 8 10-24x7/8" flat head screws, 6 of which attach through M-lok slots to square nuts. The remaining 2 screws attach to the ACC chassis' threaded mounting points near the front action screw. By attaching here I hoped to add some stiffness to the forend.

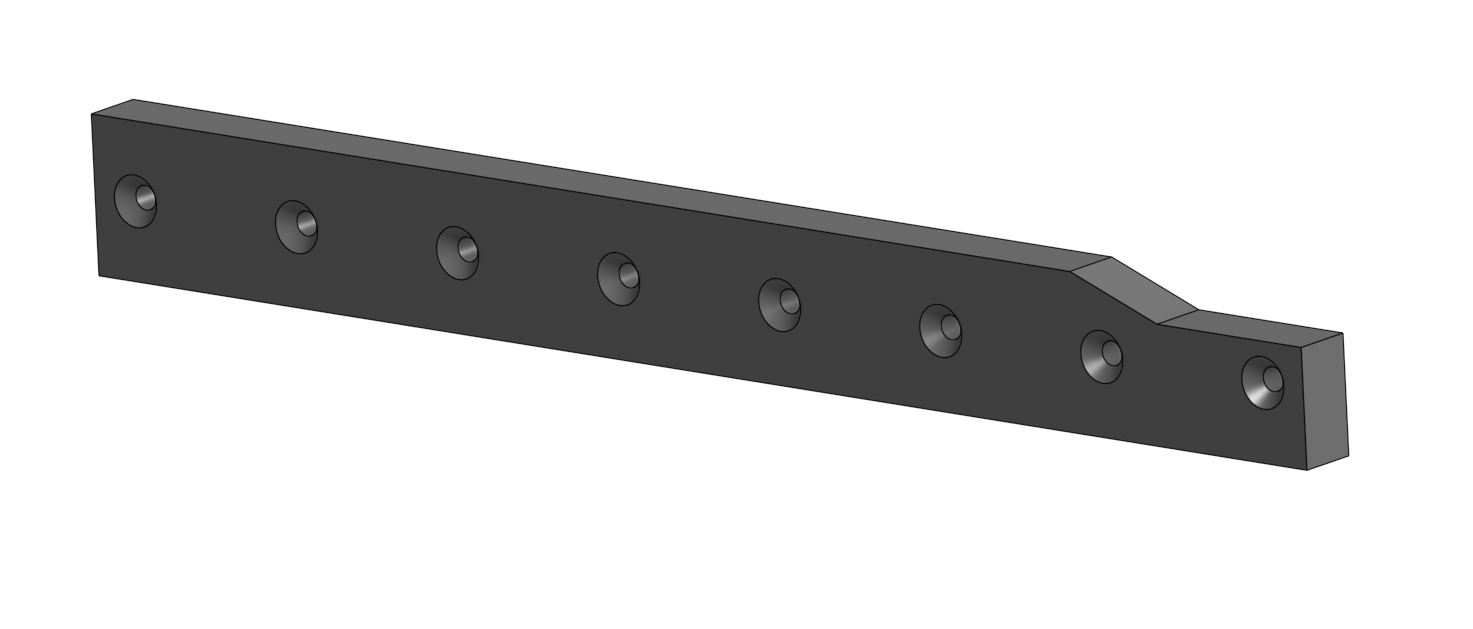

Each weight is an 11.8" x 1 1/4" x 1/2" piece of A36 bar stock. If there's interest, I can post schematics and BOM for those wanting to build their own.

CAD screenshots:

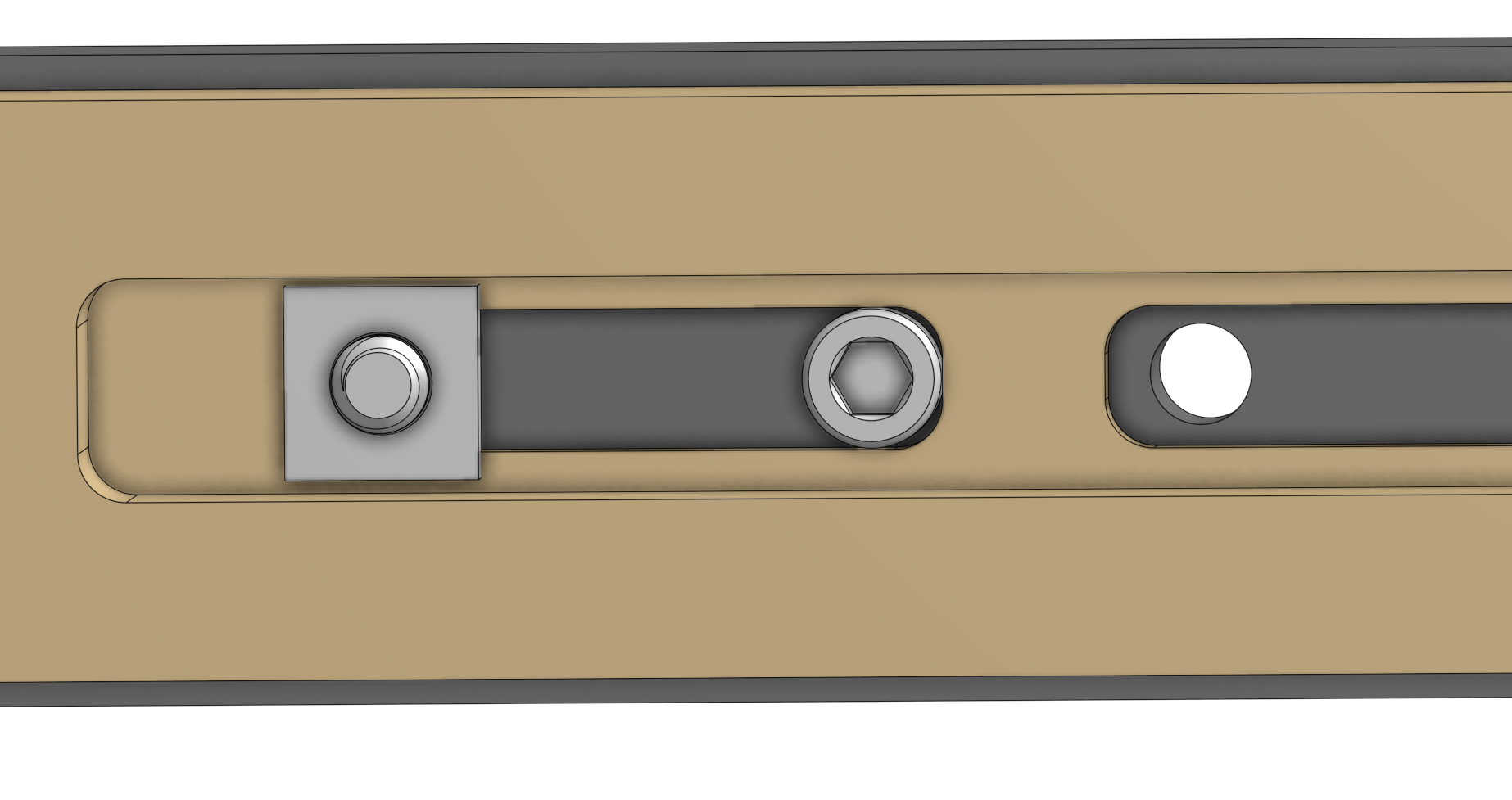

View of the back of the m-lok slots showing the 8-32 anchor screw and the square nut.

Fabrication:

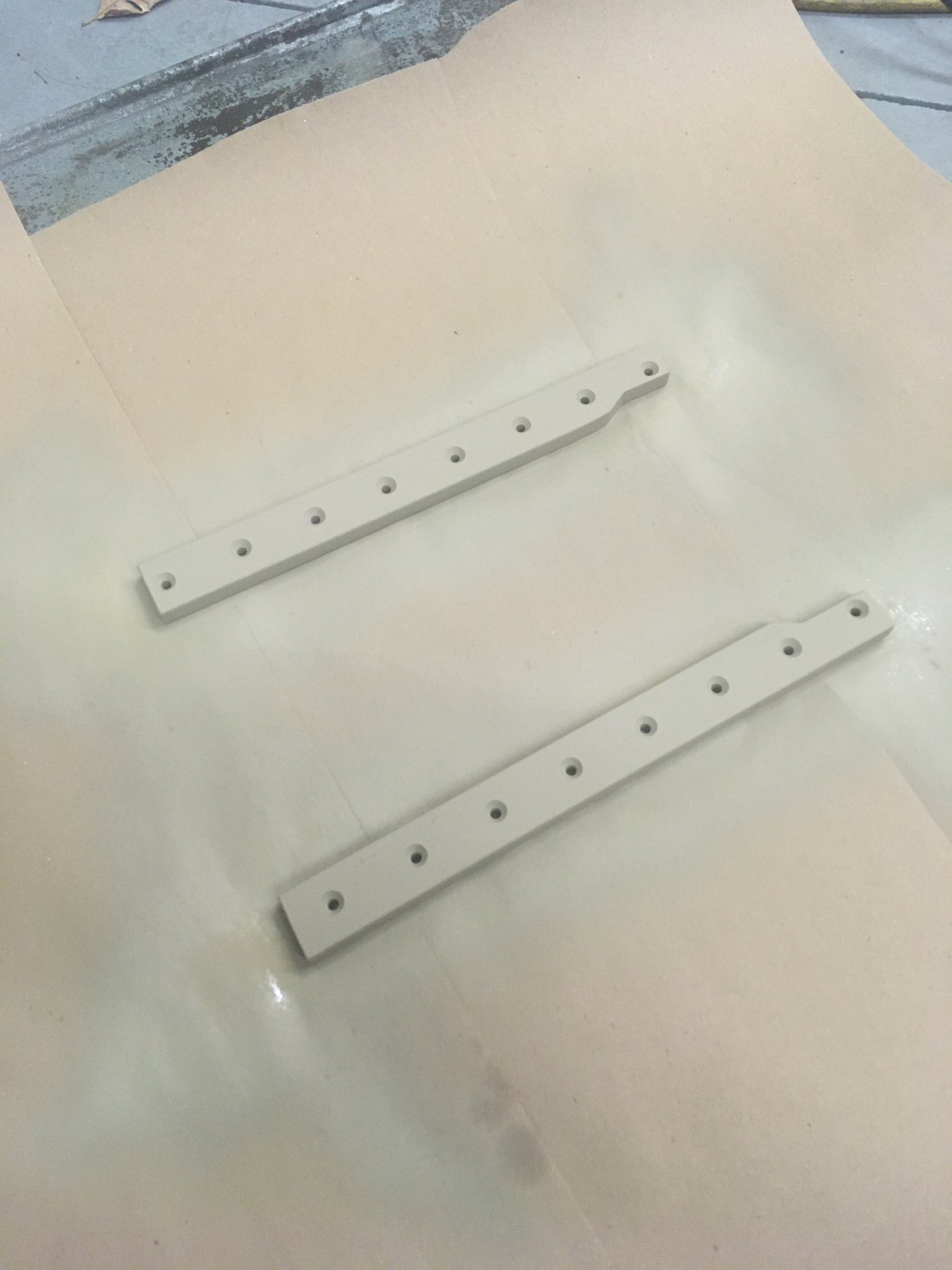

Forgive the crudity, this was done with an angle grinder and a drill press.

Test Fit

Paint

Installed and marked with wax to indicate slippage.

Test day

So far so good. No slippage. I did 50 rounds worth of barricade practice today and right away I appreciate the extra surface area on the bottom of the forend. It's hard to explain but there are a few ways it I can see it helping me grip and stabilize the rifle on a bag.

I have been wanting to add some weight to my .308 to help with stability, recoil, etc. I looked at the MDT weight kits but at $60 per .78lbs they are out of my budget. I'm not sure what MDT makes their weights out of, but at that price it must be something fairly exotic. I don't see a need for that, so sketched this up and cobbled it together out of A36. It's about $20 worth of steel and $20 worth of hardware.

Design Insights:

I wanted to add 4lb's to the rifle, move the CG slightly rearward, and also try to stiffen the forend if possible. The arca rail should not be obstructed, but adding surface area to the bottom of the forend is desirable. As such, the weights should be mounted as low as possible without obstructing the arca rail.

Because each weight is about 2 lbs I had some concerns about the weights sliding around under recoil. The MDT weights have lugs that interface with the M-Lok slots. I don't have a mill, so I was having a hard time deciding how to do this. In the end I decided to place a few 8-32 socket head cap screws on the back side which are aligned with the front wall of an M-lok slot. Each weight is attached by 8 10-24x7/8" flat head screws, 6 of which attach through M-lok slots to square nuts. The remaining 2 screws attach to the ACC chassis' threaded mounting points near the front action screw. By attaching here I hoped to add some stiffness to the forend.

Each weight is an 11.8" x 1 1/4" x 1/2" piece of A36 bar stock. If there's interest, I can post schematics and BOM for those wanting to build their own.

CAD screenshots:

View of the back of the m-lok slots showing the 8-32 anchor screw and the square nut.

Fabrication:

Forgive the crudity, this was done with an angle grinder and a drill press.

Test Fit

Paint

Installed and marked with wax to indicate slippage.

Test day

So far so good. No slippage. I did 50 rounds worth of barricade practice today and right away I appreciate the extra surface area on the bottom of the forend. It's hard to explain but there are a few ways it I can see it helping me grip and stabilize the rifle on a bag.

Last edited: