@ELR researcher,

Sorry, i read it again. Now i know you can't confirm 800grain bullet at 4000fps.

But i still like the idea of 800 grain 50 cal bullets at 4000 fps. Only the future will show who is right here.

@badassgunworks,

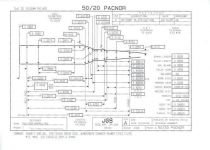

regarding the starting point of this thread. Honestly, I think nobody, really nobody can say anything about the 12.7x114mm because nobody has a cartridge print or knows the exact specifications of the cartridge. 12.7x114 = not 14.5x114. I don't know if it's really just a 14.5x114 necked down to 12.7. maybe other changes were made.

Now to 20mm cases.

I found a lot of different info on this, on too many different sites... and I really don't know what to think about it. various information from 3200 to 4000 fps with (50 cal) 750 grain and 800 grain bullets.... whatever. I'm also really tired of looking for information that can't be properly confirmed. If it takes 100k, 150k or 300million psi to get 4000fps...speculating about it without testing it in the real world makes me just tired.

The only thing I can confirm. Various companies and people have tried to necked down a 20mm case to 15mm, 14mm and 50 cal. But not one of those was a commercial success.

@Dan Warner

I don't want to say that in an ugly way but you can just eat popcorn or share your thoughts with us.

What was the issues on 14.9 SOP Cartridge? Where are the Errors? Why wasn't it a commercial success?

Sorry, i read it again. Now i know you can't confirm 800grain bullet at 4000fps.

But i still like the idea of 800 grain 50 cal bullets at 4000 fps. Only the future will show who is right here.

@badassgunworks,

regarding the starting point of this thread. Honestly, I think nobody, really nobody can say anything about the 12.7x114mm because nobody has a cartridge print or knows the exact specifications of the cartridge. 12.7x114 = not 14.5x114. I don't know if it's really just a 14.5x114 necked down to 12.7. maybe other changes were made.

Now to 20mm cases.

I found a lot of different info on this, on too many different sites... and I really don't know what to think about it. various information from 3200 to 4000 fps with (50 cal) 750 grain and 800 grain bullets.... whatever. I'm also really tired of looking for information that can't be properly confirmed. If it takes 100k, 150k or 300million psi to get 4000fps...speculating about it without testing it in the real world makes me just tired.

The only thing I can confirm. Various companies and people have tried to necked down a 20mm case to 15mm, 14mm and 50 cal. But not one of those was a commercial success.

@Dan Warner

I don't want to say that in an ugly way but you can just eat popcorn or share your thoughts with us.

What was the issues on 14.9 SOP Cartridge? Where are the Errors? Why wasn't it a commercial success?

Last edited: