Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6.5 Creedmoor

- Thread starter Sportin Wood

- Start date

I having issue trying for figure out how people are getting the velocities they are posting. I am shooting a Longrange Rifles Inc 6.5CM Kreiger 1:8.5 twist 27" barrel, my load is 41.5gr of H4350 with 140gr Amax and 210M primers. I am pushing 2767fps. My primers are showing signs of flow around the firing pin, but I have no signs of pressure on my brass. I am leery of pushing it much more since I am already over the max load. Does any one have any advice?

That firing pin flow is probably just a larger firing pin hole and not a real sign of pressure. Are the outer edges of the primer still rounded? If so then I wouldn't worry but you do what you feel comfortable with. That said some chambers are different and barrels show pressure sooner so you might not be able to get the pressures others do.

I having issue trying for figure out how people are getting the velocities they are posting. I am shooting a Longrange Rifles Inc 6.5CM Kreiger 1:8.5 twist 27" barrel, my load is 41.5gr of H4350 with 140gr Amax and 210M primers. I am pushing 2767fps. My primers are showing signs of flow around the firing pin, but I have no signs of pressure on my brass. I am leery of pushing it much more since I am already over the max load. Does any one have any advice?

If I'm not mistaken, 41.5 is not max load. The 41.5 on Hornadys box is just an advertised recommended starting load. Most factory boxes I've seen and most reloads end up between 42-43 grains. Start at 41.5 and work up.

Yes they do. It's one of the cartridges that's listed very conservative. The factory load was developed at 41.5grns and that is what is listed on the box. Due to powder lot variances there is usually between that and 42.5grns actually in the cases.

Just work up slow and stop where your rifle tells you to stop.

Just work up slow and stop where your rifle tells you to stop.

Finally got some 6.5 Creedmoor time in..bareel break in and some load development

For my fellow CREEDMOOR nuts out there:

EDIT: There has been some discussion about the primer pockets in the Hornady 6.5 Creedmoor brass and I did find that they are not as uniform as pretty much any other brass I have loaded over the years (and that is TENs of thousands). I did not measure the pockets, but did find that a few primers went in too easy, almost to the point where I first thought that the seater punch sometimes had not picked up a primer to insert. Most primers were a little harder than what you normally feel (I always use a hand primer..NEVER one with a bunch of leverage) to get to seat and then there were a few that either would not accept a primer at all or were nearly impossible to seat....so hard that I could not feel the primer bottoming in the pockets....had to squeeze some of them so hard that it was scary! What I did with the ones that were apparently somewhat undersized pockets was to gently (BY HAND!!) run my crimp remover into them and that seemed to fix the problem. I have never seen such variability in primer pockets on ANY caliber of brass, whether it be high dollar stuff, regular new brass or once, twice three times fired stuff. Going to be interesting to see how well these primer pockets hold up as they get loaded over and over. Just a comment.....I suppose it COULD be the primers, but then I buy these things by the bricks and have NEVER, EVER run into this where it was due to primers not being of uniform size....Just thought I should toss that in there to add to the pool of knowledge/answers about the Hornady brass. END OF EDIT.

What I did with the ones that were apparently somewhat undersized pockets was to gently (BY HAND!!) run my crimp remover into them and that seemed to fix the problem. I have never seen such variability in primer pockets on ANY caliber of brass, whether it be high dollar stuff, regular new brass or once, twice three times fired stuff. Going to be interesting to see how well these primer pockets hold up as they get loaded over and over. Just a comment.....I suppose it COULD be the primers, but then I buy these things by the bricks and have NEVER, EVER run into this where it was due to primers not being of uniform size....Just thought I should toss that in there to add to the pool of knowledge/answers about the Hornady brass. END OF EDIT.

Today I finally got some time on a day where the wind wasn't howling and the temps were in the 45 to 50 degree (f) range to make a trip out to shoot my newly put together 6.5 Creedmoor. The gun is a Krieger LW Varmint profile, a 8 inch twist rate (stainless) barrel with a finished length of 26 inches , Timney trigger, Remmy 700 S/A trued up/blue printed action with a Sako extractor installed in the bolt, scope is a Vortex Viper PST 6 to 24 X 50 1st focal plane MOA/MOA (Vortex says that the reticles cover .18 MOA) on a Picatinny rail. Stock is a Choate Machine with a Karsten's cheek piece. Before any of you go off on me about the stock...I think I was the ergonomic model for Choate when they designed this stock..it fits me PERFECTLY and is weighty enough to lend a good degree of stability when I shoot in matches. I weighed this rig and it is 14.5 pounds as it will be used in matches with everything mounted on it.. This is the first Vortex PST that I have tried and, so far, it seems to me that the reticles are a tiny bit on the thick side, but when I get to firing actual targets they could turn out to be just right. Quite good optics, though...I can see holes in the target better through the scope on the rifle than I can with my spotting scope!! (I guess I need a 2500 buck or whatever Swarovski like my buddy has, huh? But, THAT is NEVER gonna happen!!)

Main objective today was to do the break in as per Krieger, which I did using Hornady SST 129s over Varget...Calculated (using Quick Load) velocity was 2665, but it turned out to be more like 2750 over the chrono. I didn't really shoot this for groups..mainly these were for the break-in process, but I did want to get it printing pretty much where I pointed it for when I started to shoot my test loads. Did it all according to Krieger's web site advice on breaking a barrel in.

Once the barrel seemed to be not making copper, I started in on the 24 loads I made up for the first testing...sort of in accordance with Berger's advice..for a person that does NOT like jamming bullets. So, I loaded them with Federal GM210M primers and 42 grains of Reloader 17 pushing the new Lapua Scenar 136 L (136 grain, advertised BC .545) bullets seated to .010, .050, .090 and .130 off the lands (6 rounds for each distance to be shot in groups of three). I did load several rounds each in lower .5 grain increments so I could see if there were any pressure signs as I shot them working up toward the 42 grainers. No pressure signs at all in my rifle...no marks on the head of the brass, primers looked fine with only a TINY pretty normal looking crater (couldn't catch your thumb nail on it at all) and good, easy bolt lift...no bind at all. As I shot through the set, I found only one round that made the bolt a little hard to close and I think that was likely due to a piece of brass that was a little "chubbier" that its buddies. Velocity results were forecast by Quick Load to be:

.010 off the lands 2832 fps

.050 off the lands 2847 fps

.090 off the lands 2868 fps

.130 off the lands 2876 fps

And they chrono'd (averages)

.010 off the lands 2935

.050 off the lands 2929

.090 off the lands 2957

.130 off the lands 2987

So, they were a little faster than I expected them to be.

I shot off of my (kind of slippery) back pack and supported the rear of the stock with my hand/sand bags. All of the groups were shot at 220 yards with pretty much NO wind.The very last group I shot (.130 off the lands) produced a group of .316 MOA and that was the best with the worst of the 8 3 shot groups being almost 1 MOA and the average for all of them being .678 MOA. I did discover that my chosen targets for the test had bull eyes that were too small....they would be obscured way too easily by the reticle in the scope, so I have changed the targets I will be using in the future so that they have a center dot big enough to where I will be able to tell better EXACTLY where the gun is/should be pointed. (which will be about 1 1/4 inch diameter for use at 220 yards). I think that there are three things at work here that caused me to be disappointed in the groups I shot: (1) the barrel is likely not really even close to being broken in and the groups it shoots will tighten up in a while. (2) Me sliding around on the slippery pack ( this isn't the greatest thing for accuracy during load development, but the matches I shoot in require "field ready" and so I use a pack.....Remember the old "Train like you fight and Fight like you train"?? (3) The size of the bulls eyes I chose for this outing were too small to allow accurate, consistent target alignment.

Hopefully, with some equipment changes, the next outing will give me more USEFUL info, as I really didn't learn a lot today.........

In closing, I will stick in the usual disclaimer: THIS IS NOT INTENDED TO BE RELOAD ADVICE and I recommend that you work up loads yourself in increments that work in YOUR RIFLE, since they all seem to be different!!

Hopefully this was somewhat helpful to someone. I'm hoping that the next trip out with this gun for load testing gives me better info with which to make decisions to wind up with the best loads. i want to use the new Lapua Scenar 136 L bullets as I belive they are one of the better bullets out there.....not to mention that I have 1000 of them !!! If you have any questions/comments relating to all of this, drop me a PM or hit me at [email protected]

!!! If you have any questions/comments relating to all of this, drop me a PM or hit me at [email protected]

See ya....and have fun shooting!!

For my fellow CREEDMOOR nuts out there:

EDIT: There has been some discussion about the primer pockets in the Hornady 6.5 Creedmoor brass and I did find that they are not as uniform as pretty much any other brass I have loaded over the years (and that is TENs of thousands). I did not measure the pockets, but did find that a few primers went in too easy, almost to the point where I first thought that the seater punch sometimes had not picked up a primer to insert. Most primers were a little harder than what you normally feel (I always use a hand primer..NEVER one with a bunch of leverage) to get to seat and then there were a few that either would not accept a primer at all or were nearly impossible to seat....so hard that I could not feel the primer bottoming in the pockets....had to squeeze some of them so hard that it was scary!

Today I finally got some time on a day where the wind wasn't howling and the temps were in the 45 to 50 degree (f) range to make a trip out to shoot my newly put together 6.5 Creedmoor. The gun is a Krieger LW Varmint profile, a 8 inch twist rate (stainless) barrel with a finished length of 26 inches , Timney trigger, Remmy 700 S/A trued up/blue printed action with a Sako extractor installed in the bolt, scope is a Vortex Viper PST 6 to 24 X 50 1st focal plane MOA/MOA (Vortex says that the reticles cover .18 MOA) on a Picatinny rail. Stock is a Choate Machine with a Karsten's cheek piece. Before any of you go off on me about the stock...I think I was the ergonomic model for Choate when they designed this stock..it fits me PERFECTLY and is weighty enough to lend a good degree of stability when I shoot in matches. I weighed this rig and it is 14.5 pounds as it will be used in matches with everything mounted on it.. This is the first Vortex PST that I have tried and, so far, it seems to me that the reticles are a tiny bit on the thick side, but when I get to firing actual targets they could turn out to be just right. Quite good optics, though...I can see holes in the target better through the scope on the rifle than I can with my spotting scope!! (I guess I need a 2500 buck or whatever Swarovski like my buddy has, huh? But, THAT is NEVER gonna happen!!)

Main objective today was to do the break in as per Krieger, which I did using Hornady SST 129s over Varget...Calculated (using Quick Load) velocity was 2665, but it turned out to be more like 2750 over the chrono. I didn't really shoot this for groups..mainly these were for the break-in process, but I did want to get it printing pretty much where I pointed it for when I started to shoot my test loads. Did it all according to Krieger's web site advice on breaking a barrel in.

Once the barrel seemed to be not making copper, I started in on the 24 loads I made up for the first testing...sort of in accordance with Berger's advice..for a person that does NOT like jamming bullets. So, I loaded them with Federal GM210M primers and 42 grains of Reloader 17 pushing the new Lapua Scenar 136 L (136 grain, advertised BC .545) bullets seated to .010, .050, .090 and .130 off the lands (6 rounds for each distance to be shot in groups of three). I did load several rounds each in lower .5 grain increments so I could see if there were any pressure signs as I shot them working up toward the 42 grainers. No pressure signs at all in my rifle...no marks on the head of the brass, primers looked fine with only a TINY pretty normal looking crater (couldn't catch your thumb nail on it at all) and good, easy bolt lift...no bind at all. As I shot through the set, I found only one round that made the bolt a little hard to close and I think that was likely due to a piece of brass that was a little "chubbier" that its buddies. Velocity results were forecast by Quick Load to be:

.010 off the lands 2832 fps

.050 off the lands 2847 fps

.090 off the lands 2868 fps

.130 off the lands 2876 fps

And they chrono'd (averages)

.010 off the lands 2935

.050 off the lands 2929

.090 off the lands 2957

.130 off the lands 2987

So, they were a little faster than I expected them to be.

I shot off of my (kind of slippery) back pack and supported the rear of the stock with my hand/sand bags. All of the groups were shot at 220 yards with pretty much NO wind.The very last group I shot (.130 off the lands) produced a group of .316 MOA and that was the best with the worst of the 8 3 shot groups being almost 1 MOA and the average for all of them being .678 MOA. I did discover that my chosen targets for the test had bull eyes that were too small....they would be obscured way too easily by the reticle in the scope, so I have changed the targets I will be using in the future so that they have a center dot big enough to where I will be able to tell better EXACTLY where the gun is/should be pointed. (which will be about 1 1/4 inch diameter for use at 220 yards). I think that there are three things at work here that caused me to be disappointed in the groups I shot: (1) the barrel is likely not really even close to being broken in and the groups it shoots will tighten up in a while. (2) Me sliding around on the slippery pack ( this isn't the greatest thing for accuracy during load development, but the matches I shoot in require "field ready" and so I use a pack.....Remember the old "Train like you fight and Fight like you train"?? (3) The size of the bulls eyes I chose for this outing were too small to allow accurate, consistent target alignment.

Hopefully, with some equipment changes, the next outing will give me more USEFUL info, as I really didn't learn a lot today.........

In closing, I will stick in the usual disclaimer: THIS IS NOT INTENDED TO BE RELOAD ADVICE and I recommend that you work up loads yourself in increments that work in YOUR RIFLE, since they all seem to be different!!

Hopefully this was somewhat helpful to someone. I'm hoping that the next trip out with this gun for load testing gives me better info with which to make decisions to wind up with the best loads. i want to use the new Lapua Scenar 136 L bullets as I belive they are one of the better bullets out there.....not to mention that I have 1000 of them

See ya....and have fun shooting!!

Last edited:

SGM buy a Hornady Headspace tool with a .400 insert or use a SIZED 40SW case and measure your fired decapped cases, use the longest measured fired case or cases as your reference, bump the shoulder back .001, I guarantee you your case head separation will be a thing of the past. From what I read your sizing your brass too much, hence the case head separations, your technique of sizing until a stripped "bolt falls free" is incorrect, you should feel slight resistance half way down, which is exactly what a case with a shoulder bumped .001 will have. I do both, use a HSG and the stripped bolt technique with slight resistance half way down, never once in 35k rifle rounds reloaded have I had case head separation, please stop doing as I have always done and adjust your technique, Rob01 has more experience with the 6.5 Creedmmor than any one else on the Hide, or Planet for that matter, this not a powder lot problem but a sizing too much problem.

I'm finishing up a couple of builds in this caliber,

Can't wait to put those together and try some loads out,

Will post results on this thread

BTW: this is an awesome thread , and thanks to all those 6.5CM shooters,

we can find some good info here ,

Please keep this going

Can't wait to put those together and try some loads out,

Will post results on this thread

BTW: this is an awesome thread , and thanks to all those 6.5CM shooters,

we can find some good info here ,

Please keep this going

I found 3 pounds of h4350 and purchased 200 130gr Berger VLDs and 50 Barnes 127 LRX. I have 25 140gr VLDs which I've had the pleasure of killing 2 deer with, one at 515 the other at 485. I've also missed 2 at 520 and 540... I was using the IMR 4350 and both of my misses we're substantially short and the temperature was in the 20's each time vs the upper 60's when I developed the load. Thus the switch to h4350. What I am looking at is Berger load data for the 130s stating max load data WAY lower (41.6 @ 2727fps) than some of the loads I see here. My rifle is a Remington 700 with a 26" Lilja 3 groove 1:8 twist. Am I missing something? Thanks in advance!

I found 3 pounds of h4350 and purchased 200 130gr Berger VLDs and 50 Barnes 127 LRX. I have 25 140gr VLDs which I've had the pleasure of killing 2 deer with, one at 515 the other at 485. I've also missed 2 at 520 and 540... I was using the IMR 4350 and both of my misses we're substantially short and the temperature was in the 20's each time vs the upper 60's when I developed the load. Thus the switch to h4350. What I am looking at is Berger load data for the 130s stating max load data WAY lower (41.6 @ 2727fps) than some of the loads I see here. My rifle is a Remington 700 with a 26" Lilja 3 groove 1:8 twist. Am I missing something? Thanks in advance!

I have a Savage Predator Hunter 6.5 Creedmoor and loaded up to 44.1 gr H4350 with the Berger 130 Hunting VLD with no signs of pressure. My COAL was around 2.85". (0.040" off the lands)

I found something I feel is getting close..43.4 gr H4350 1x Hornady brass CCI BR2 behind a 130VLD just at the lands running 2920 @10' thru a CED M2. I have shot 3 five shot groups at 200 yards, each measuring just under an inch. I plan on running Berger's 24 load test next weekend to see if the depth changes affect anything for the better or worse.

One question for those who shoot a lot. Do you notice the first shot of the day out of a cold barrel is several feet faster than the 2nd, 3rd, etc? Thanks in advance.

One question for those who shoot a lot. Do you notice the first shot of the day out of a cold barrel is several feet faster than the 2nd, 3rd, etc? Thanks in advance.

SGM buy a Hornady Headspace tool with a .400 insert or use a SIZED 40SW case and measure your fired decapped cases, use the longest measured fired case or cases as your reference, bump the shoulder back .001, I guarantee you your case head separation will be a thing of the past. From what I read your sizing your brass too much, hence the case head separations, your technique of sizing until a stripped "bolt falls free" is incorrect, you should feel slight resistance half way down, which is exactly what a case with a shoulder bumped .001 will have. I do both, use a HSG and the stripped bolt technique with slight resistance half way down, never once in 35k rifle rounds reloaded have I had case head separation, please stop doing as I have always done and adjust your technique, Rob01 has more experience with the 6.5 Creedmmor than any one else on the Hide, or Planet for that matter, this not a powder lot problem but a sizing too much problem.

1. I did get a Hornaday Headspace guage.

2. The issue was that the lock ring on the die had turned about 1/4 turn. The cases in question all had .010" of headspace. I was able to go through all my reloaded lots and determine which ones were bad. Those were all pulled apart and set aside.

3. It was not a powder issue as I loaded new cases with the same load and I got the same dope. Still running 2820 with Berger 140 Hybrids.

It's been solved for a while now, but thanks. The lock ring on the Redding dies have a set screw that hold the ring in place. If you over tighten it you will booger the threads and won't be able to turn the lock ring. However, if you don't get the set screw tight enough, over time it will loosen and then it can (and probably will) move. In my case about a quarter turn, which is about .007".

I've got 5-6 reloads on some of my brass with no problems; however, it's all getting replaced with new brass and the old stuff is getting pitched just to be safe.

Now on to more important things like converting my 308 to a 6 Creedmoor.

.

2. The issue was that the lock ring on the die had turned about 1/4 turn. The cases in question all had .010" of headspace. I was able to go through all my reloaded lots and determine which ones were bad. Those were all pulled apart and set aside.

It's been solved for a while now, but thanks. The lock ring on the Redding dies have a set screw that hold the ring in place. If you over tighten it you will booger the threads and won't be able to turn the lock ring. However, if you don't get the set screw tight enough, over time it will loosen and then it can (and probably will) move. In my case about a quarter turn, which is about .007".

Yeah...I DO NOT like the lock rings that use a set screw against the threads AT ALL!!! I always have changed those out for the type of lock ring that "squeezes" the die to lock it in place. You can buy that type of lock ring here and there...they usually come in bunches of two or three and they are made by FORSTER or are knock-offs of the FORSTER type made by RCBS or whoever. Yeah..it costs a little bit to buy/use these if your chosen dies have the thread boogering set screw type, but I keep several of these in my reloading junk to change out the ones that booger

Like these:

http://www.ebay.com/itm/Lyman-Die-L...045?pt=LH_DefaultDomain_0&hash=item4acdf5b9b5

Last edited:

I finally got ahold of another hundred Hornady factory loads and they shot great in my rifle. I've been having a hard time getting the 140gr AMAX to group well in my rifle and after seeing these factory rounds shoot I thought there was hope after all. I opened one up to see what powder charge weight they were coming with from the factory and was surprised to see that it was not H4350 inside but some other extruded powder that is all black.

It weighed in at 41.3gr, any idea what they have switched to? The sticker on the outside of the box still says 41.5gr H4350 - no surprise there, the last box I checked in May of 2013 was 43.1gr but was still H4350. This stuff looks nothing like the H4350 I have used over the last year.

It weighed in at 41.3gr, any idea what they have switched to? The sticker on the outside of the box still says 41.5gr H4350 - no surprise there, the last box I checked in May of 2013 was 43.1gr but was still H4350. This stuff looks nothing like the H4350 I have used over the last year.

I finally got ahold of another hundred Hornady factory loads and they shot great in my rifle. I've been having a hard time getting the 140gr AMAX to group well in my rifle and after seeing these factory rounds shoot I thought there was hope after all. I opened one up to see what powder charge weight they were coming with from the factory and was surprised to see that it was not H4350 inside but some other extruded powder that is all black.

It weighed in at 41.3gr, any idea what they have switched to? The sticker on the outside of the box still says 41.5gr H4350 - no surprise there, the last box I checked in May of 2013 was 43.1gr but was still H4350. This stuff looks nothing like the H4350 I have used over the last year.

I wonder if this is their new superformance powder???

Are any of you loading N-160? I got my hands on 8# and just sent payment on a 26" Bartlein 6.5 CM barrel by SAC for my Gen 2 DTA. I can't wait to play with this thoroughbred caliber.

Hornady uses H4350 in that load and I am sure that is what that is. With the way H4350 as well as other powders have been selling and the way powder producers have been making it as fast as they can maybe it hasn't been sitting around as long and looks a little different.

They use Varget in the 120grn load but would not be using it in the 140grn load.

They use Varget in the 120grn load but would not be using it in the 140grn load.

Another short session at the range today with the Krieger/trued 700 Remmy/Timney/Choate Machine 6.5 Creedmoor. So far there have been 55 rounds down the tube of the 6.5 Creedmoor including the first batch that were for break-in only. This is a group of 5 I shot today as part of the load development process/ladder. This was shot at 220 yards, front rest was an old pack I have full of junk, rear was old shot bags with DCG in them with my hand squeezing for elevation control. Load was Hornady brass used just as it comes from the factory, 42 grains (weighed) of Reloader 17, 136 grain Lapua 136L Scenars, Fed 210M primer.....seated to .010 off the lands. Velocity chrono'd at 2935 AVG on my PACT chrono..HV and LV were around +/- 15 fps.

Shoots real good so far...I figure that it is giving around .307 MOA (with the semi-unsteady shooter/rests) without much development having been done with varying amounts of powder or different powders.......just the first load I kind of worked up to using what I had most of on hand.....should get somewhat better using the fireformed cases rather than just whatever from Lapua and whatever velocity and powder combination works out best...So far no signs of pressure...good primers, no sticky bolt...actually comes up REAL nice and easy....

The primers in the green case are (from top to bottom) .130 off the lands, .050 off and .010 off. All the same 42.0 grain Reloader 17 loads.

I attached a couple of pictures.

Shoots real good so far...I figure that it is giving around .307 MOA (with the semi-unsteady shooter/rests) without much development having been done with varying amounts of powder or different powders.......just the first load I kind of worked up to using what I had most of on hand.....should get somewhat better using the fireformed cases rather than just whatever from Lapua and whatever velocity and powder combination works out best...So far no signs of pressure...good primers, no sticky bolt...actually comes up REAL nice and easy....

The primers in the green case are (from top to bottom) .130 off the lands, .050 off and .010 off. All the same 42.0 grain Reloader 17 loads.

I attached a couple of pictures.

A few loads that are working extremely well in my AI AE.

130 Berger Hunting VLD

CCI BR2

42.6 H4350

COAL 2.810"

140 A-Max

CCI BR2

41.9 H4350

COAL 2.825"

130 Berger Hunting VLD

CCI BR2

42.6 H4350

COAL 2.810"

140 A-Max

CCI BR2

41.9 H4350

COAL 2.825"

Curious if anyone else is seeing unusually quick loose primer pockets in the Hornady brass. My load is 42.6 gr of 4350 and shows no signs of pressure. However after only 2 loadings, primers seat with out any resistance. A couple of other local shooters are also seeing this.

I purchased this two times fired brass from a fellow hider ,Curious if anyone else is seeing unusually quick loose primer pockets in the Hornady brass. My load is 42.6 gr of 4350 and shows no signs of pressure. However after only 2 loadings, primers seat with out any resistance. A couple of other local shooters are also seeing this.

and in the process of priming the already formed cases

the primer was going in so easy that it felt like there was no primer at all

There was no resistance at all from the primer pocket

I've got 5 firings and primer pockets are good.I purchased this two times fired brass from a fellow hider ,

and in the process of priming the already formed cases

the primer was going in so easy that it felt like there was no primer at all

There was no resistance at all from the primer pocket

I purchased this two times fired brass from a fellow hider ,

and in the process of priming the already formed cases

the primer was going in so easy that it felt like there was no primer at all

There was no resistance at all from the primer pocket

Very interesting…..I'm seriously concerned that I am going to have to start culling brass after only a few firings. I was so impressed with the Hornady brass until this issue. Shot with a couple of other Creedmoor shooters this morning and they are witnessing the same thing. On a brighter note…..man of all the calibers I have had…this Creedmoor is an absolute hammer. Love this thing!!!!

Very interesting…..I'm seriously concerned that I am going to have to start culling brass after only a few firings. I was so impressed with the Hornady brass until this issue. Shot with a couple of other Creedmoor shooters this morning and they are witnessing the same thing. On a brighter note…..man of all the calibers I have had…this Creedmoor is an absolute hammer. Love this thing!!!!

In my case, I suspect that the brass I purchased was maybe fired more then two times or they were loaded near max ,

I have new brass as well and before I blame the brass I want to witness this happening to me with new brass, I 'll post results

Tell you what will help, TULA Russian primers are ever so slightly tighter than BR2s, might give that a try, I got 5K from Natchez.

Tell you what will help, TULA Russian primers are ever so slightly tighter than BR2s, might give that a try, I got 5K from Natchez.

I heard that today from another Creedmoor shooter. Will have to give them a try.

Tell you what will help, TULA Russian primers are ever so slightly tighter than BR2s, might give that a try, I got 5K from Natchez.

Thanks JGorski, that's not a bad idae,

I heard thoseb are good quality primers too

Do you guys FL size your brand new Hornaday brass? if so how much do you back the shoulder down on new brass

Do you guys FL size your brand new Hornaday brass? if so how much do you back the shoulder down on new brass

All I do is expand the necks to clean them up.

All I do is expand the necks to clean them up.

All my Creedmoor brass is once fired but the above is what i do with any new brass. Just clean up the mouth and load them up. I don't worry about shoulder bump until after they are fired in the chamber and then it's about .001" of a bump.

Feelluckypunk, I started using N160 when I couldn't get H4350. I shoot 140 VLD from a 26 inch barrel loading 44.2g N160 which gets me 2875fps. 44.2 is a little on the hot side, I found 2 nodes that shot really well. One at 43.6 and the other at 44.2. It works very well for me. I can get H4350 now and choose to stay with the N160.

I am curious,what kind of primers are the guys using that are reporting loose primer pockets?I am asking this because I changed last week from Fed210M to CCI and experienced the same thing on 2x fired brass.Never had this problem with the Feds.With the CCI primers some are loose and some not.I contacted CCI and they ask me if I use a primer pocket uniformer and if I did to stop,which I don't anyway.My load is.

42.3 GRS H4350

140 Amax

COAL 2.800

Going back to FED primers

CCI is suppose to get back to me this week on this lot# of primers.

42.3 GRS H4350

140 Amax

COAL 2.800

Going back to FED primers

CCI is suppose to get back to me this week on this lot# of primers.

Are any of you loading N-160? I got my hands on 8# and just sent payment on a 26" Bartlein 6.5 CM barrel by SAC for my Gen 2 DTA. I can't wait to play with this thoroughbred caliber.

I loaded 41.2gr N160 behind 140gr AMax and my best 5 shot group was at .146 at 100 yards

I am curious,what kind of primers are the guys using that are reporting loose primer pockets?I am asking this because I changed last week from Fed210M to CCI and experienced the same thing on 2x fired brass.Never had this problem with the Feds.With the CCI primers some are loose and some not.I contacted CCI and they ask me if I use a primer pocket uniformer and if I did to stop,which I don't anyway.My load is.

42.3 GRS H4350

140 Amax

COAL 2.800

Going back to FED primers

CCI is suppose to get back to me this week on this lot# of primers.

My load is a 140 AMax over 42.6 H4350 and I have some brass with 6-8 firings with Remington primers I've thrown out 10 or so out of the original 100 in that lot because of primers, but most of them are still truckin' on.

I am curious,what kind of primers are the guys using that are reporting loose primer pockets?I am asking this because I changed last week from Fed210M to CCI and experienced the same thing on 2x fired brass.Never had this problem with the Feds.With the CCI primers some are loose and some not.I contacted CCI and they ask me if I use a primer pocket uniformer and if I did to stop,which I don't anyway.My load is.

42.3 GRS H4350

140 Amax

COAL 2.800

Going back to FED primers

CCI is suppose to get back to me this week on this lot# of primers.

My load is 42.6 of H4350 with Fed 210's. I am sure hoping Tula primers will fill the now loose pockets or I will be looking at all new brass very soon….which sucks big time after only 2X fired.

Finally a use for my N160 that I bought 10 years ago!!

Does it still light up?

I'll let you guys know if it doesn't. I am just surprised at how much darker it is than the H4350...

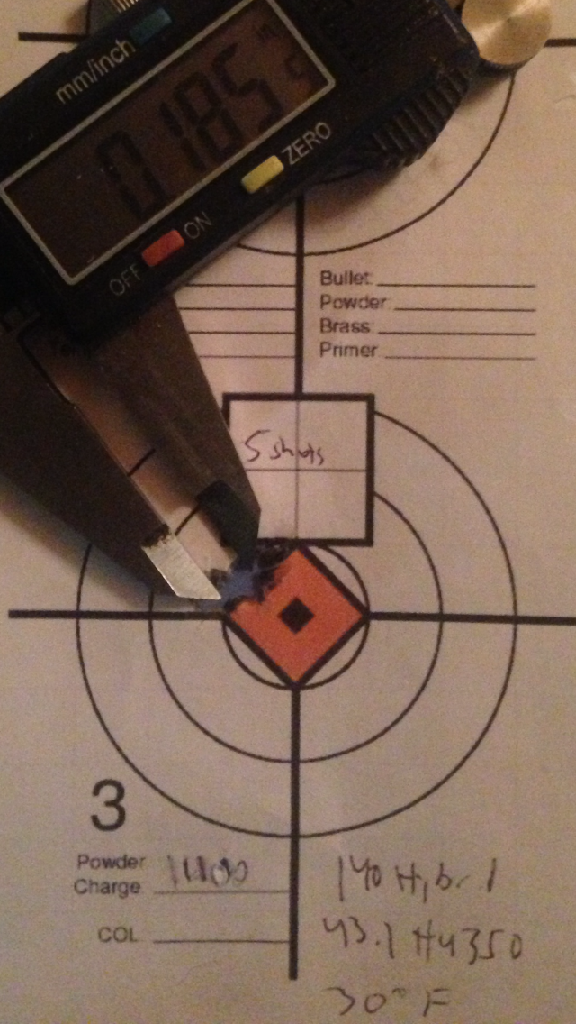

So I loaded up 140 Berger Hybrids and Ran 2 Different OCWs over the long weekend. My end results are kind of astounding to me and the high node I found has me asking for a sanity check from fellow reloaders.

This is in my 25" Bart barrel chambered by Aaron Roberts of Roberts Precision Rifles (+1 to Aaron great smith, I highly reccomend his work)

140 Berger Hybrid

COAL 2.805"

210M Primers

Once fired hornady brass

H4350

I had two low nodes at 42.9 and 42.3 Grs of 4350 they grouped well.

I had a great node at 43.1grains. This is the first one that I thought I could actually mass produce and have success with. During this OCW I ran all the way up to 43.7 and did not have the slightest hint of pressure. So I went home and loaded another OCW up to 44.1

Sure enough 44.1grs of 4350(Not a typo) produced the best accuracy node of the day. Again no pressure. The bolt felt great and ran smoothly and the primers look excellent.

My question for you other seasoned re loaders out there is that is this higher node 'dangerous'? Or is it just going to burn my barrel? Shorten my brass life?

This is in my 25" Bart barrel chambered by Aaron Roberts of Roberts Precision Rifles (+1 to Aaron great smith, I highly reccomend his work)

140 Berger Hybrid

COAL 2.805"

210M Primers

Once fired hornady brass

H4350

I had two low nodes at 42.9 and 42.3 Grs of 4350 they grouped well.

I had a great node at 43.1grains. This is the first one that I thought I could actually mass produce and have success with. During this OCW I ran all the way up to 43.7 and did not have the slightest hint of pressure. So I went home and loaded another OCW up to 44.1

Sure enough 44.1grs of 4350(Not a typo) produced the best accuracy node of the day. Again no pressure. The bolt felt great and ran smoothly and the primers look excellent.

My question for you other seasoned re loaders out there is that is this higher node 'dangerous'? Or is it just going to burn my barrel? Shorten my brass life?

So I loaded up 140 Berger Hybrids and Ran 2 Different OCWs over the long weekend. My end results are kind of astounding to me and the high node I found has me asking for a sanity check from fellow reloaders.

This is in my 25" Bart barrel chambered by Aaron Roberts of Roberts Precision Rifles (+1 to Aaron great smith, I highly reccomend his work)

140 Berger Hybrid

COAL 2.805"

210M Primers

Once fired hornady brass

H4350

I had two low nodes at 42.9 and 42.3 Grs of 4350 they grouped well.

I had a great node at 43.1grains. This is the first one that I thought I could actually mass produce and have success with. During this OCW I ran all the way up to 43.7 and did not have the slightest hint of pressure. So I went home and loaded another OCW up to 44.1

Sure enough 44.1grs of 4350(Not a typo) produced the best accuracy node of the day. Again no pressure. The bolt felt great and ran smoothly and the primers look excellent.

My question for you other seasoned re loaders out there is that is this higher node 'dangerous'? Or is it just going to burn my barrel? Shorten my brass life?

All of the above. There's really no point to be running 44 grains of powder (especially in the summer) because your DEFINETLY going to get over pressure when it's hot. I found a very accurate load at 42.6 h4350 same OAL. I don't care who gets pissed off at this... H4350 ain't magical. I've experienced BIG swings in velocity with hot and cold. And there's really no big advantage at all to gain another 50 fps when in reality it's going to shoot another 35 yards supersonic but at the cost of your barrel, brass , ect. I'm not trying to be a know it all. Just giving you my honest opinion.

I think you got a weak batch of powder. Hornandy sometimes runs 43 gr in their load to keep up velocity.

Now recent 140 a max loads have indeed been loaded with a different powder. Still waiting to hear back what they switched to. The new powder is black and has a hole in the center of it. Its clocking slower and producing slightly higher pressures

Now recent 140 a max loads have indeed been loaded with a different powder. Still waiting to hear back what they switched to. The new powder is black and has a hole in the center of it. Its clocking slower and producing slightly higher pressures

Similar threads

- Replies

- 10

- Views

- 529

- Replies

- 17

- Views

- 2K