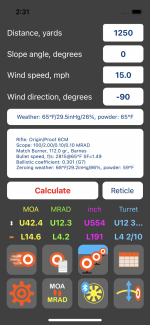

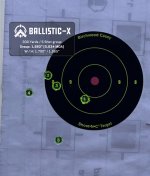

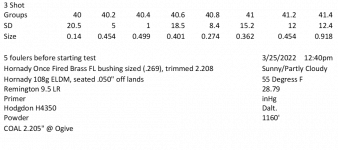

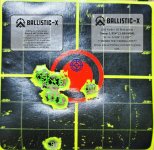

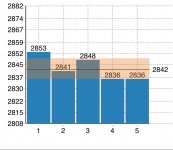

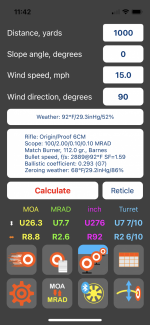

Hey Everyone, I am working up a load for my new MPA BA PMR Pro in 6CM. I have done an initial seating depth test, and found that the rifle really likes .050 - .060 off the lands, so that is where all my rounds are are seated. I just did a 12 round load/ladder test this afternoon, and want to share my results for some feedback. I dont want to go any higher in velocity and want to keep it below 3000fps, which my test has done. I am wondering if I should try out a 5 round load test between 42.2 and 42.4, or possibly between 42.8 and 43.2 (see chart). Any feedback is appreciated. Thanks!

Components are: Hornady 108 ELD-M, Hornady brass, CCI 200 primers, WinStaball 6.5 powder. Brass is all FL sized, trimmed, chamfered.

View attachment 7819205

Relaying data per 2022 Hodgdon Annual Manual : 43 gr is their max @ 3080 fps , 59,500 psi ,24" barrel ,same brass, WNLR primer ,same bullet .

Barrel may speed up ,may not as it gets rounds through it.

Some pick a speed ,and play with seating depth , others find where it groups best with powder charge ,then play with seating depth . Your choice . When I worked my load, I wanted 3000 fps or a tad over. I started .020 off ,got to speed ,but groups weren't quite as good as I expected. Set bullet .010 off ( 108 eldm ) and groups got as small as me and my rifle are capable of producing ( real small , I'm happy ).

Thoughts were asked for, and furnished ....nothing more or less. Just one man's experience. Best of luck to you ,and happy shootin .

Iffin ya already know the above ,disregard this post........I was bored.