Gday Fellas.

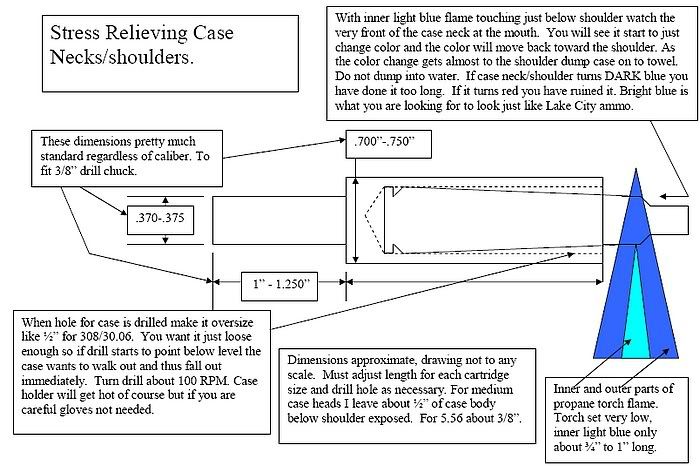

I got thinking today about case annealing after reading through various articles on the web and noticed a fair lack of consistency regarding the temperatures people like to reach whilst annealing, in particular the Tempilaq indicator used.

For example, whilst reading an annealing article on 6mmBR.com aka accurateshooter, I stumbled across some information regarding Hornady releasing their annealing kit with different forms of tempilaq indicator across the board... this got me thinking.

People must obviously use different temp indicators for different areas of the case... But which one is the best?

Clearly there must be a general answer to this question regardless of the case.

Is it 475 degrees 1/4" below the shoulder as sufficient?

or is it 700 degrees 1/4" below the shoulder as sufficient?

Im sure those of us out there using indicator pastes/pens have discovered at what point you achieve that nice looking "blue yet shiney" perfectly annealed case.

So i guess in a nut shell, how do you guage this indication of "properly annealed" AND if you do use Tempilaq which version do you use and at what part of the case do you like to use it on.

Let the discussion begin

I got thinking today about case annealing after reading through various articles on the web and noticed a fair lack of consistency regarding the temperatures people like to reach whilst annealing, in particular the Tempilaq indicator used.

For example, whilst reading an annealing article on 6mmBR.com aka accurateshooter, I stumbled across some information regarding Hornady releasing their annealing kit with different forms of tempilaq indicator across the board... this got me thinking.

People must obviously use different temp indicators for different areas of the case... But which one is the best?

Clearly there must be a general answer to this question regardless of the case.

Is it 475 degrees 1/4" below the shoulder as sufficient?

or is it 700 degrees 1/4" below the shoulder as sufficient?

Im sure those of us out there using indicator pastes/pens have discovered at what point you achieve that nice looking "blue yet shiney" perfectly annealed case.

So i guess in a nut shell, how do you guage this indication of "properly annealed" AND if you do use Tempilaq which version do you use and at what part of the case do you like to use it on.

Let the discussion begin